Material ConneXion introduces composites around the world

Physical and virtual material libraries and access to designers should attract composites industry participation.

Material ConneXion (New York, N.Y.) is a global materials consultancy that delivers information about the latest advanced and innovative materials to designers worldwide. If you’re a designer for Addidas, Motorola or Toyota, where do you get information about cutting edge material developments? Multiple technical journals, newsletters and conferences? Perhaps, but Material ConneXion has become a favored option by many because it eliminates weeding through university- and marketing-speak, concisely highlighting a material’s innovation — e.g. new viscose fiber with 10X increase in dye absorption for reduced processing costs. It also does this with the originality, elegance and efficiency of an Apple design. Case in point, subscribers can walk through the rows of visually stunning materials in brick-and-mortar libraries around the world — which are also available online — but can also receive a box of curated wonder materials every few months via the ActiveMATTER service.

Material ConneXion was started in 1997 by George M. Beylerian, founder of the contemporary design store Scarabaeus in New York City and the Beylerian Limited brand of furniture which was acquired by Steelcase (Grand Rapids, Mich.). The other members of Material ConneXion’s executive team bring global expertise in publishing, consumer product design, architecture and industrial design. But then comes the science. Vice president of library and materials research Andrew Dent has a Ph.D. in materials science from the University of Cambridge in England and previously held research positions at Rolls Royce (London, England) — specializing in turbine blades for the present generation of jet engines — and at the Center for Thermal Spray Research, State University of New York (SUNY, Stony Brook, N.Y.), as well as performing research for the U.S. Navy, DARPA, NASA, and the British Ministry of Defense. In fact, over half of Material ConneXion’s staff are material scientists, specialists in a particular material technology (polymers, ceramics, etc.) or sustainability experts. The company seeks to bridge the gap between science and design.

Material ConneXion has over 70,000 members worldwide and advises companies, designers and engineers from offices in the U.S., Italy, Japan, Korea, Sweden and Thailand. Though many of its customers request confidentiality, it also serves many on the Fortune 500 list. Its clients include IKEA, General Motors, Fisher Price, Nike, Samsung, Samsonite and Target, as well as thousands of architects and industrial design firms.

Besides all of the innovative materials, which I love, and Material ConneXion’s modern approach, I believe its reach into the industrial design community offers value to companies in our industry. Suppliers of unique composite materials and processes should apply to have these added to the MCX library. No fee is required and submissions are reviewed by an independent jury, which adds 30 to 40 new materials to the library each month. Out of 7,500 plus materials, currently 400 are composites or materials used in composites.

“We want to receive materials submissions from composite material suppliers,” says VP of library and academic programs Michael LaGreca. “We talk to thousands of designers on a continuing basis, and want to make sure they have the latest in materials developments and potential solutions.” Companies interested in submitting materials for library selection should contact Access@materialconnexion.com .

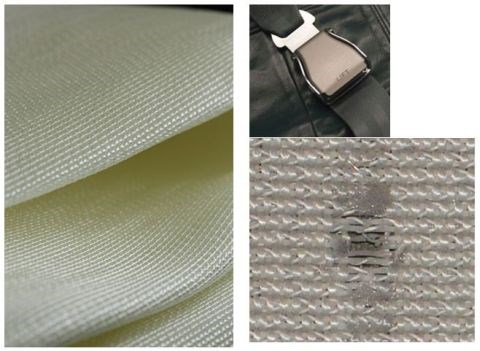

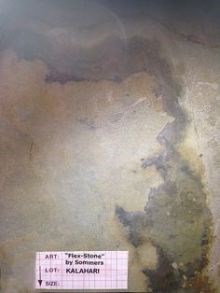

The other opportunities I see are for composites materials to be included in Material ConneXion’s publications and technical reports and in the presentations it gives at global trade shows and conferences. For example, it exhibited at the 2014 International Boatbuilders’ Exhibition and Conference (IBEX, Sep. 30 - Oct. 2, Tampa, Fla.), displaying an on-site library of materials in the Composites Pavilion. Samples included a textile woven to be auxetic — having a negative Poisson’s ratio so that it becomes thicker when stretched, not thinner — and fabric-like material made from thin schisms of Italian stone combined with layers of adhesive, textile and resin to form a flexible veneer, less than 0.5 mm/0.02 inch in thickness and 0.4 kg/m² (.08 lb/ft²) in areal weight (which is less than a carbon fiber/epoxy twill 2/2 prepreg with 44 percent resin content). Composites could gain that type of exposure in events for other industries.

Auxetic textile woven to thicken with tensile loading (left). Applications include safety belts, straps and ballistic/blast protection, for example, this single layer of Zetix fabric after 8 grenade blasts from 1 meter distance shows a shrapnel strike point with zero penetration despite heat damage. SOURCE: Material ConneXion (left), Auxetix (Exeter, U.K.) and Advanced Fabric Technologies (Houston, Tex.).

“What we brought to IBEX is just a small sample of the materials that we think could be translated to the marine industry which are currently being used in other industries like apparel and automotive,” said MCX material scientist Sara Hoit. “This cross-pollination often provides a direct solution or sparks an idea for a new innovation.”

|

Flexible stone material made from real Italian stone, adhesive, fabric and resin, less than 0.5mm thick. SOURCE: Sommers Plastics Products (Clifton, N.J.)

And that is another benefit I see for companies in the composites industry — to learn about new materials that might improve or add value to their current systems and technologies or be inspired to take their materials into totally new industries and applications.

Related Content

3D-woven composites find success in aerospace, space

CAMX 2024: Bally Ribbon Mills experts are displaying the company’s various joints, thermal protection system (TPS) technologies and other 3D woven composites for mission-critical applications.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreHighly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreCFRP planing head: 50% less mass, 1.5 times faster rotation

Novel, modular design minimizes weight for high-precision cutting tools with faster production speeds.

Read MoreVIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.

Read More