Processes

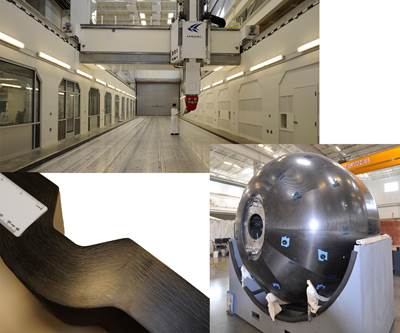

Big machines, small tolerances

An examination of the lengths Janicki Industries (Sedro-Woolley, Wash.) goes to ensure dimensional precision in its massive CNC-machining operations.

Read MoreJanicki Industries: Breaking the mold

Once known only as a toolmaker, Janicki offers unique precision, production capability and problem solving as it pioneers leading-edge composites technology.

Read MoreLFI process: Molding strong and attractive spa enclosures

Dynasty Spas (Athens, Tenn.) finds a composite alternative to wood hot tub surrounds in a polyurethane (PU)-based long fiber injection (LFI) solution implemented by Romeo RIM Inc. (Romeo, Mich.).

Read MoreRail car doors: Waterjet cutter shapes panels with precision

When GFMI Aerospace & Defense (Fountain Valley, Calif.) was approached with the task of cutting hundreds of glass fiber/epoxy panels for use in the manufacture of rail car doors, it relied on a waterjet cutting system supplied by OMAX Corp. (Kent, Wash.).

Read MoreBuilding a better tail boom

Out-of-autoclave carbon fiber/thermoplastic demonstrator is a 30 percent lighter drop-in replacement for an existing aluminum design.

Read MorePolyurethane pultrusion: Next-gen equipment

Two years ago, Martin Pultrusion Group (MPG, Oakwood Village, Ohio) finalized the design of a next-generation pultrusion machine and has developed a proprietary direct injection box design for high-pressure pultrusion of polyurethane composites.

Read MorePultruding polyurethane: Sheet pilings break boundaries

High-pressure pultrusion process creates polyurethane composite sheet pile system with the strength and stiffness to compete with steel.

Read MoreFlow-front dynamics: Heat and vacuum hold

Three infusion experts talk about ways and means to avoid erratic flow fronts during resin infusion processes.

Read MoreAiming infusion at the application

With so many process variables to play with, how do you know which new solutions that promise better, faster infusion are right for your application?

Read MoreCutting train doors with precision

GFMI Aerospace & Defense uses waterjet cutting technology to produce glass fiber/epoxy door panels for a major rail car manufacturer.

Read More