Bio-based, fire-resistant composites become mainstream

Projects use Duplicor prepreg panels with highest Euroclass B fire performance without fire retardants for reduced weight, CO2 footprint in sustainable yet affordable roofs, high-rise façades and modular housing.

Figure 1. Large-scale innovation, mainstream projects. Lightweight Duplicor prepreg composite panels have been used to restore 13,300 square meters of roofing for the Van Gendt Hallen heritage site (left), to enable The Pulse’s open-plan high-rise office tower (center) and to build 99 affordable yet flexible modular housing units for the Netherlands elderly care organization Cicero. Photo Credit, all images: Holland Composites/Duplicor, The Pulse of Amsterdam, flickr.com (center) and Qbix (right).

As explained in CW’s 2019 tour article, Holland Composites (Lelystad, Netherlands) has been developing composite solutions in architecture and construction for decades. The company’s first project, an energy-efficient 6 × 3 × 3-meter (l, w, h) modular housing unit for universities called Space Box, was an instant success, selling thousands of units. The company went on to complete a variety of high-profile projects, fabricating and installing composite roof structures and façades, including its Raficlad system of translucent composite panels that can be made in any color and incorporate visual fibers, logos or even dried organic matter.

But Holland Composites’ founders, Pieterjan Dwarshuis and Sven Erik Janssen, could see the industry needed a better solution than the carbon fiber-reinforced polymer (CFRP) and resin-infused glass fiber panels they had been using. “We faced a serious challenge with these composites in the mainstream building market because the polyester, phenolic and epoxy resins we were using are considered toxic materials,” explains Janssen. “It’s very difficult now to put these into buildings. The industry is instead looking to more natural and bio-based materials. The other issue is that these petroleum-based resins burn.”

“We were always struggling with getting the fire performance right with composite materials,” agrees Eric van Uden, managing director of Solico Engineering (Oosterhout, Netherlands). His company has provided structural engineering for Holland Composites construction projects since 2005. “We could use highly filled fire-retardant [FR] resins, but they were very costly. Because they had lower properties, we needed a lot of kilos of resin.” This then increased weight and demanded more structural support.

Now, however, Holland Composites is proposing what Janssen calls a game-changing solution: Duplicor bio-based, fire-resistant composites. “We’re using a plant-based resin with a mix of possible fibers depending on the application,” he explains. “And we no longer use PIR [polyisocyanurate] or EPS [expanded polystyrene] foams in sandwich construction, but just recycled PET foam.” The latter, he concedes, is not bio-based, “but it does help to remove plastics from the environment. Duplicor is durable, it actually stores CO2 and it is a solution to build with less material. More and more tenders in the building industry are being awarded not only on price, but also on the environmental impact of the materials and process that you use.” And, he adds, “Duplicor is affordable.”

The development of Duplicor

This technology results not only from Holland Composites’ many years of learning in developing composites for marine and construction applications, but also years spent specifically on the Duplicor approach. “Seven years ago, we started working with a company that was experimenting with a resin they made from sugarcane straw, a kind of agricultural waste,” says Janssen. “But we couldn’t infuse with it. We finally asked one of our prepreg suppliers to try putting the resin into a prepreg and that was the key. But we also saw it had a really high temperature resistance, therefore it could have good fire resistance.”

Indeed, tests in 2019 showed the resin burned much less quickly than the company’s previous composites. By November 2020, testing by fire safety specialists Efectis (Saint-Aubin, France), per the European Standard EN 13501, showed Duplicor panels successfully achieved fire classification B-s1, d0. The certificate cites panels 15-150 millimeters thick, with 200 micrometers of ultra-high solids (UHS) paint, a 2.5-millimeter-thick glass fiber/bio-resin skin laminate (1,950 kilograms/cubic meter density) and 15- to 150-millimeter-thick PET foam core (40-60 kilograms/cubic meter density). “This means that Duplicor cored panels and solid laminates have no flame spread and are very hard to burn,” says Janssen.

“It’s not Grade A according to our European standard, but it reaches the highest level of the vertical combustible materials, which is actually the highest value you can reach with composite materials without any FR additives,” adds van Uden. “That’s enough for use in European buildings. The regulation is that the first 3 meters should be Class B and then up to 12 or 14 meters you can have Class C or D. Above 30 meters that should again be Class B. So, this material suits as-is for all building applications.”

Duplicor production

Holland Composites continued development, patenting the Duplicor technology and bringing fabrication in-house. In 2021, it built a second 4,000-square meter factory, next to the original Holland Composites building in Lelystad, dedicated to Duplicor production (see Fig. 3 below).

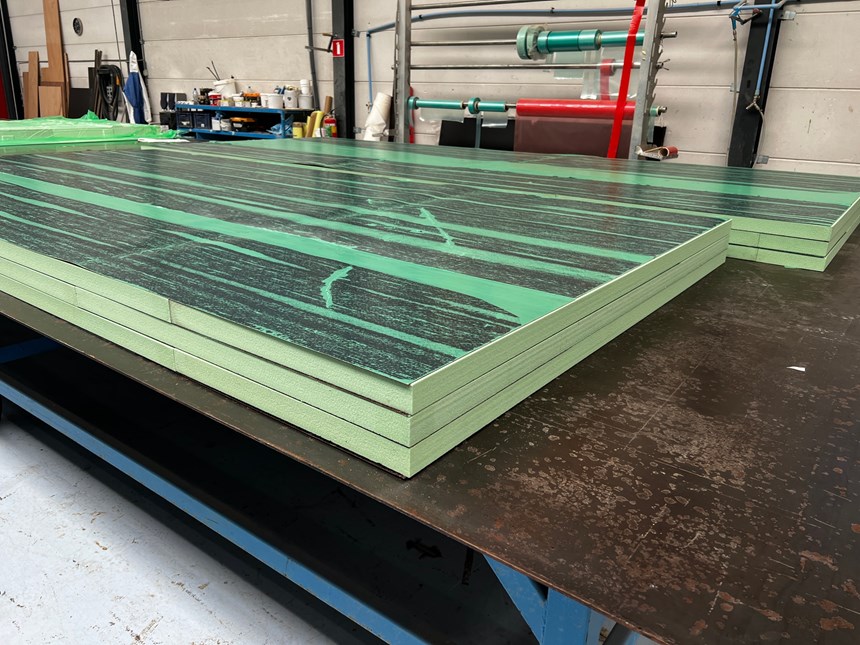

The brownish-colored resin arrives in bulk containers. “We mix it with accelerators and a thermal hardener, and then feed that into our prepreg machine,” says Janssen. “We have installed a 35-meter-long prepreg manufacturing line which is the same that is used for carbon fiber/epoxy prepregs, but custom made for us. We can make thousands of square meters of Duplicor prepregs with high fiber content. These are not 200 gram/square meter carbon fiber/epoxy prepregs, but instead materials for 1,600-gram quadraxial laminates with 35% resin content. So, you’re talking about a 2.5 kilogram/square meter prepreg material, which is designed for building purposes — i.e., one layer and done.”

Rolls of prepreg are produced according to the specifications for each project and then converted into panels. To further aid production speed, Zund (Altstätten, Switzerland) automated cutters are used to cut the prepreg, which pick-and-place robots then put into molds. “We then use the set of skills developed for Holland Composites’ projects,” says Janssen. “We can use these molds in a hot press, oven or autoclave to make profiles, laminate sheets or simple sandwich panels.” The Duplicor factory has two 12-meter-long hot-press production lines which can produce panels or profiles up to 3.5 meters long and 1.25 meters wide. It also has four ovens, sized roughly 4 × 4 meters. Parts can also be made next door using Holland Composites’ 6.5 × 2.2-meter autoclave, its 12 x 4-meter heated vacuum table — traditionally used for resin infusion — or one of several modular ovens developed to expand up to 15 × 10 × 3.5 meters for large marine projects.

Engineering Duplicor structures

“One of the first things we had to do was to determine the engineering parameters so we could design with Duplicor and ensure we meet the Eurocodes building standards in Europe,” explains van Uden. “We did a whole test program with Holland Composites to characterize Duplicor materials in terms of stiffness, strength and degradation due to moisture, temperature, etc. We tested different varieties of their material with biaxial fabrics, woven roving and unidirectional [UD] reinforcements, as well as different core materials.”

The Duplicor laminates were higher in performance than previous composites. “We began discussing how we could make structures thinner,” says van Uden. “With the previous process, that always seemed difficult to do. We would have a 200-300-millimeter-thick foam core wrapped with dry fibers and then injected with resin. But with this new prepreg system, we could make structures more like shells so that if we needed core material to stiffen panels, then it is only 10-20 millimeters thick.”

That makes a huge difference, says Janssen. “So, we are using less material in a thinner panel, but because it’s an integrated panel with this recycled PET foam, we can provide a high thermal insulation factor of 5.8-6.0 with a thickness of only 180 millimeters. A concrete panel with the same properties is almost 400 millimeters thick because they have to add insulation foam. Thus, with Duplicor, we can offer wall panels that are 15 to 22 centimeters slimmer compared to traditional aluminum/wooden and concrete constructions, which provides extra usable floor space. In Amsterdam, you easily pay €5,000 per square meter for that floor space.”

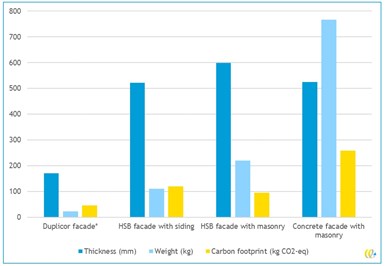

LCA study comparing Duplicor to conventional façade construction where HSB stands for timber frame construction. *The carbon footprint of the Duplicor façade panel also includes transport. Photo Credit: Duplicor LCA report from CE Delft

Holland Composites also studied Duplicor’s carbon footprint compared to concrete and wooden frame construction (abbreviated as HSB in the Netherlands). In 2021, it commissioned a lifecycle analysis (LCA) study from the sustainability research and consulting firm CE Delft. The study compared Duplicor to three traditional constructions for façades based on an R-value of 5.8 to 6.0. Note that typical R-values per inch thickness are 0.8 to 1.2 for concrete, 1.25 for softwood lumber and 5.0 for extruded polystyrene foam. “The analysis showed that we can achieve that insulation performance in a structural facade weighing just 24 kilograms per square meter,” says Janssen. “Compare that to concrete at 450 kilos per square meter. So, we actually offer more space for the same building plan and use less material.”

Results from the LCA study comparing the four façade panels showed Duplicor offered superior performance: 3-4 times lower thickness, 5-30 times lower weight and 2-6 times lower carbon footprint. “If you use plant-based materials, you actually store CO2,” notes Janssen. How these benefits can be exploited in mainstream building projects is highlighted in the following case histories.

The Pulse

The Pulse is a two-tower, 56,000 square-meter development being completed in Amsterdam’s Zuidas business district. It was designed by well-known architects MVSA (Netherlands) to integrate a state-of-the-art office tower and a high-rise residential building with an urban forest and walkpath as well as restaurants, a cinema and supermarket. Duplicor was selected for the façade of the 24-story office tower, which features natural light and sweeping views via some of the largest, open-plan offices in the Netherlands. Construction began in 2021.

“The design of the building’s façade is canting more as you move up,” notes Janssen. “With every floor, the glass window leans a bit more forward. MVSA also used different element types on each floor to create some movement in the design. So, there are 16 different types of façade elements and also a one-piece corner element — all with the glass window integrated into them.”

The design for the Duplicor façade began with engineering partner Solico. “It started with Holland Composites’ idea of having a box-like structure with an outer and inner shell,” recalls van Uden. “You could then fill in that gap with a combination of recycled PET foam and rock wool or even blown-in insulation. Each element would then come out of the mold as an integrated structure with outer and inner shell and insulation material, but it also needed to be cost-effective. And that was really a new way of making these kinds of structures.”

“We then made finite element models for each type of element,” he continues, “and used those to determine wind loads, snow loads and self-weight to deal with the glass, which is actually the majority of the weight because the composite itself is quite light. We made our first calculations and then we started to optimize. For example, we needed some extra stiffening in some corners and more shape in some panels to accommodate insulation, etc.”

Figure 2. Enabling light-filled, flexible, sustainable spaces. The Pulse office tower uses Duplicor composite façade elements as the load-bearing closure between its concrete floors. The molded units integrate solar panels on top and canted, floor-to-ceiling glazing to achieve the building’s innovative design while also providing thermal insulation, fire resistance and interior/exterior finish in one pass, reducing build time, cost and CO2 emissions. Photo Credit: The Pulse of Amserdam, flickr.com, Duplicor

“De Groot & Visser [Gorinchem] designed the system of support points to the building, where they can do the adjustments in the vertical direction and they also designed the seals required for watertightness, because that’s actually their specialty,” says van Uden. “And then we engineered how to connect those seals in the façade element and how to reinforce the attachment points — for example, where local reinforcements were needed.”

“We created 1,200 elements, measuring roughly 4 × 4 meters each,” says Janssen. “Each element has a recess so that you can fit PV [photovoltaic] solar panels on top.” These provide sustainable power without being seen yet are easy to access and maintain. “We had to perform the B Class fire test with these PV panels included. And we also integrated cabling for the solar panels and finished each element with a metallic finish coating. We never use a gel coat.” Elements were supplied to the building site as needed, where they received window glazing before being craned to each floor and installed by two De Groot & Visser installation specialists.

This construction process moved very quickly, says van Uden. “The building process entailed making concrete floors and columns and then you just close those out with these composite façade elements where everything is integrated: structure, insulation and glazing. And that installation goes quite fast because each element is lightweight and easy to handle. You lift it to the concrete floor, adjust it, complete the attachment and watersealing and then move to the next one.” These elements also form the interior surface of the office spaces. “That is what you touch on the inside,” he explains. “There is no other finishing. So, it’s a very efficient, sustainable type of construction.”

Figure 3. Duplicor Process Chain

Van Gendt Hallen

The Van Gendt Halls are five factory buildings from the late 19th century located in central Amsterdam that are being sustainably renovated into an energy-neutral national monument which will house the Drift Museum, as well as a mix of office, commercial and community spaces.

“We have these historically listed buildings in Holland, that have a preservation status,” says Janssen. “Their renovation should maintain the building’s original construction and shape, but also bring the building up to new standards — better insulation for reduced energy consumption and more windows to increase natural light inside, etc. However, the existing structure is typically old wood and thin, rusty steel, so there’s not enough strength left to support this renovation. And yet we cannot take away the beautiful wooden frameworks due to the building’s historical status. So, it creates a real problem.”

“If you don't want to add numerous columns and girders, then you have to keep weight of the new and renovated structures very low,” adds van Uden. “That’s why this project chose to use Duplicor sandwich panels for the whole roof.” A key enabler was that Duplicor could recreate the iconic “steam hoods” on top of these buildings, originally built for the Royal Dutch Factory of Tools and Railway Equipment. “All of the steam and heat from the locomotives and steelwork went out of the building through louvered hut structures on the roof,” explains Janssen. “The construction team had already calculated that wood framed construction weighed too much. But by using lightweight Duplicor composite sandwich panels, they could restore the original shape of these hoods as well as use higher rated thermal insulation, install PV solar panels and other energy-saving systems, and also meet fire resistance requirements.”

Duplicor was used not only for the steam huts, but also for the flat roof panels. “And in between these is a glass window system to bring sunlight inside the building as well,” notes Janssen. “The flat panels we made included a recess for holding all of that glazing and formed the structure to carry all of that load.” Again, the weight of the glass was much more than that of the composite roof panels.

Figure 4. Restoring the roof of Van Gendt Hallen. Duplicor panels enabled restoration of this steam locomotive factory heritage site, including iconic “steam hood” roof structures, while adding windows and solar cells to flat areas without exceeding the original wood and steel skeleton’s load capability. Photo Credit: Braaksma Roos architects (top two images)

The design process began with the architects’ initial designs. “We used those to determine the loads for the various roof structures and how the connections would work,” says van Uden. “We then specified the reinforcements and dimensions for the Duplicor panels and built the FEA [finite element analysis] models to validate and optimize the design. We put all the loads into the FEA models and designed the steam hood connections to the roof structure and also for the flat panel and glazing systems. We then could optimize the laminate sequence, core material and thickness for the Duplicor panels and add reinforcements to support the solar panels, etc.”

The steam hoods were fabricated into modules on the ground, lifted into place with a crane and then assembled into the building structure. Van Uden notes that the wind loads for these were very high, requiring a lot of fasteners to make the connections to resist those loads. The same process was used to complete the flat roof sections. The project has now been completed and was immense, says Janssen. “We renovated almost 13,000 square meters of roofing.”

Refurbishing and future-proofing

“I think there is a big market in refurbishing buildings,” says van Uden. “There are a lot of old buildings here in the Netherlands, but also in other countries, that need to be refurbished to comply with new fire regulations and also for increased loading. I think there’s a whole new industry there and composites can help.”

“Designers and engineers now have a solution to recreate the original historical building without being limited by conventional, heavier building materials which prevent them from optimizing the renovation,” says Janssen. “Our solution not only enables performance to current standards but also to meet future energy needs and withstand how our climate is changing. We are providing the thermal protecting skin of a building, and the better you can protect and thermally insulate your building, the better you’re prepared for what is coming in the near future. If we can then also include PV panels on our roofs and façades, even better, because this is needed for the future as well.”

“I also see the potential to refurbish buildings by extending living space outside the building by adding balconies and other structures,” says van Uden. “Those buildings from the 60s are quite cramped, quite small spaces, and designs are evolving to integrate more interior light as well as exterior plants and trees into buildings. So, I think in the whole spectrum of refurbishing, composites can really play an important role.”

Modular housing, no compromises

These two case histories are exciting, notes Janssen, because they are not the typical high-profile projects for composites where money is no object. Van Uden agrees, “I think we can learn a lot doing those projects, but for a company it’s quite difficult to make that kind of project profitable, because they are always one-offs. Duplicor is very different because it is aimed to provide a more cost-effective composite material for mainstream projects.” Indeed, this is being demonstrated through modular housing — traditionally, a very cost-sensitive sector within construction.

“We have formed two new companies for this,” says Janssen. “We are entering the modular housing market with Qbix, and QSpace is how we started out, with the university housing, but now with Duplicor, we can optimize new designs and make them even more cost-efficient.” He notes that a lot of modular housing companies use steel containers. “But none of them can shape their modules like we can do with composite materials, and that also gives an edge for how we do the construction.”

Qbix is already being used in a project to build 99 housing modules in Limburg for the Netherlands elderly care organization Cicero. “That is being built entirely from 2D building elements — floors, walls and roofs — all made from Duplicor. We use 2D materials made in molds that can actually scale for large building projects — a kind of Lego blocks for new buildings. And another aspect of this approach can be seen in the success of IKEA, where you take home a wardrobe in three flat boxes and assemble the panels together using an easy-to-understand diagram. This is exactly what we are doing with the Qbix modular system. Flat stacked elements are transported with a design grid that you can use to create any building that you imagine.”

“And by using bio-based and recycled materials, the carbon footprint is much better than concrete,” adds van Uden. These are game-changing biocomposites for a bigger scale of building projects, says Janssen. “We are not trying to make art pieces but instead innovate the building industry on a large scale. We have better material properties, use less material and emit less CO2.”

“The building industry right now thinks all of this isn’t possible — that you must compromise on something,” he continues. “But we have worked for years to develop this lightweight, fire-resistant, composite sandwich material that is more cost-effective than the composites we had been using. But it goes further because watersealing, thermal insulation, fire protection and inside/outside finish can all be integrated into one product. And we can mold it to achieve the geometric form that architects want to create or recreate. So, there are no compromises anymore.”

Related Content

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreRead Next

Composites-reinforced concrete for sustainable data center construction

Metromont’s C-GRID-reinforced insulated precast concrete’s high strength, durability, light weight and ease of installation improve data center performance, construction time and sustainability.

Read MoreComposite thermal breaks boost window insulation value

The composite insulation systems used in windows to insulate building interiors, while rarely seen, are vital to sustainable and efficient residential and commercial construction.

Read MoreBuilding the Museum of the Future

FR composite panels provide structure, sealing and iconic facade for pioneering architecture in Dubai.

Read More