Air taxis like Lilium Jet, shown here in a rendering in flight over New York, are designed for intracity and intercity transport of 2-5 people. These aircraft, which fall under the heading of urban air mobility (UAM), feature all-electric propulsion and make significant use of composite materials. Photo Credit: Lilium

The idea of a flying car has long been heralded in popular culture, from the Jetsons cartoon in the early 1960s to the Star Wars landspeeder in the ‘70s, and many other incarnations in more recent science fiction. The promise they all put forward is a future where daily transportation could enter the third dimension and bypass the traffic and congestion that is modern commuting. Further, their assumption was that such easy transport was just around the corner — a not-insurmountable technical challenge. Today, almost 60 years post-Jetsons, it does appear that we are, finally, on the cusp of such a transportation revolution.

There are, right now, several aircraft development programs far along the manufacturing and flight-test path that aim to help ease passenger and/or cargo transport in large urban areas throughout the world within the next five years. All of these aircraft are battery-powered and depend greatly on the weight-saving, strength-giving power of composites.

Beta Technologies’ ALIA 250c UAM features four lifting rotors and one pushing rotor. It is designed to carry passengers, but one of its first jobs will be to provide human organ transport services for emergency transplant operations. The ALIA is being fabricated by Blue Force Technologies. Photo Credit: Blue Force Technologies

UAM, AAM, eVTOL

What is this transportation revolution? It goes by many names. It began with electric vertical takeoff and landing (eVTOL) aircraft, but this can be too specific at times, so the industry switched to urban air mobility (UAM). NASA prefers advanced air mobility (AAM), which covers a lot of bases and takes away the urban-focused nature of the technology — despite the fact that AAM is very much designed for the urban environment.

Regardless of the name — we’ll use the more common UAM here — aircraft of this genre are designed to perform one of two functions. One is to provide piloted or autonomous air taxi service, transporting people from point A to point B (heliport/airport-to-heliport/airport) over a distance of 25-400 kilometers, intracity or intercity. The second function is to provide autonomous cargo transport in similar environments.

The economics and metrics driving UAM are numerous, and not all can be explored here (KPMG offers a good primer on the technology and what’s behind it), but one of the biggest drivers is the rapid urbanization of the planet. By 2050, according to the UN, 68% of the world’s population — about 7.1 billion people — will live in urban areas. This will put substantial pressure on transportation infrastructure, making travel by car increasingly difficult. Expanding travel into the airspace over cities is expected to ease that pressure. Hence the burgeoning UAM market.

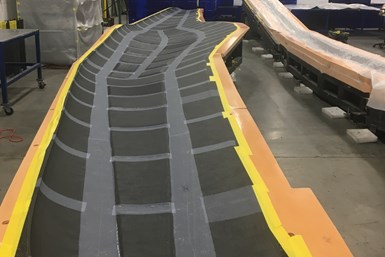

Blue Force Technologies is using liquid resin infusion to fabricate composite structures for the prototypes of Beta Technologies’ ALIA aircraft. The company is focused on unitized construction to minimize bonding and joining. Shown here is the layup of the ALIA’s tail section. Photo Credit: Blue Force Technologies

Aerospace quality, automotive quantity

Regardless of market forces and economics, UAM manufacturers have entered composites fabrication territory heretofore unexplored. UAM aircraft, to enter service, must be certified by the authority that governs air travel, similar to how large commercial aircraft are certified. In the U.S. that’s the FAA and in Europe it’s EASA. Earning that certification requires that the aircraft meet certain safety and performance metrics. Use of composites to meet certification requirements, although not trivial, is easily within reach of several common material and process combinations.

However, UAM manufacturers also are considering full-rate production volumes in the hundreds of units, if not thousands. This is a far cry from the eight-per-month rate for manufacture of the Boeing 787 or the Airbus A350. Achieving such rates will require development of process, process control and automation technologies that can repeatably, reliably and efficiently produce high-quality, on-spec aerostructures. Thus, UAM manufacturing has become the poster child for the common composites phrase, “Aerospace quality, automotive quantity.”

One of the leaders of the air taxi service is, predictably, Uber, which has created Uber Elevate, an aerial ridesharing service. Uber Elevate has contracted with several UAM manufacturing partners who will build aircraft for the company. These include Aurora Flight Sciences, Bell, Embraer, Hyundai, Jaunt Air Mobility, Joby Aviation, Overair and Pipistrel Vertical Solutions.

Mischa Pollack, vehicle design and structures lead at Uber, said during a CAMX 2020 presentation that the company anticipates initial certification of its service in a few cities by 2023, followed by expansion in 2026 and then significant scale-up in 2028. By 2035, he said, Uber Elevate expects to have aerial ridesharing services in more than 50 markets with demand for 10,000 UAM aircraft per year. “This number,” he said, “is still closer to commercial aerospace manufacturing rates, but we still need composites manufacturing to evolve.”

Technicians at Blue Force Technologies work on fabrication of the 50-foot carbon fiber/epoxy wing skin, spars and ribs for the Beta Technologies ALIA. Photo Credit: Blue Force Technologies

What does such evolution look like? Pollack’s full-rate production wish list is basically a roadmap to the industrialization that the composites industry has anticipated for several years: Up to 4,500 metric tons per year of high-modulus/high-strength carbon fiber, increased automation via automated tape and fiber placement, expanded use of compression and pultrusion processes, strategic use of fiber-reinforced additive manufacturing, automated bonding and welding, real-time inline inspection, little or no waste, increased use of low-embodied-energy materials, substantial use of recycled materials and application of sustainable energy, material and process strategies.

Fortunately, the composites industry has a few years to develop the supply chain that can meet such needs. In the meantime, how each UAM manufacturer will move into production varies. Some, as noted below, are keeping all production in-house. Some are doing prototyping in-house but will shift full-rate production to partners. Others have engaged third-party partners from the start and will maintain that strategy into production.

There are more than 100 companies today working on the development of UAM aircraft for air taxi or cargo transport services, but only a handful have been sufficiently funded to produce flying prototypes or demonstrators. They are: Beta Technologies (South Burlington, Vt., U.S.), EHang (Guangzhou, China), Joby Aviation (Santa Cruz, Calif., U.S.), Lilium (Munich, Germany), Pipistrel (Ajdovščina, Slovenia), Volocopter (Bruchsal, Germany) and Wisk (Mountain View, Calif., U.S.).

All of the UAM aircraft profiled here have several common features: First, they are relatively small, with capacity for two to four passengers, or an equivalent mass of cargo. Second, they are almost all flown autonomously. Third, they are fully electric and depend on rechargeable batteries for flight. Fourth, they rely on the use of lifting rotors that enable vertical takeoff and landing. Not every UAM manufacturer listed here was willing to share with CW how it deploys composites on its craft. What follows is a summary of information provided.

Blue Force Technologies technicians remove a cured wing spar for the Beta Technologies ALIA from its mold. Blue Force says that although infusion was chosen for prototype fabrication, it might switch to out-of-autoclave prepreg for full-rate production. Photo Credit: Blue Force Technologies

Beta Technologies

Quietly and quickly moving forward is Beta Technologies, which is developing the ALIA 250c piloted eVTOL for transport of up to five passengers. This plane features four lifting rotors and one pushing rotor. The lifting rotors are located on booms forward and aft of each over-fuselage wing; the pushing rotor is located at the rear of the plane behind the horizontal tailplane. Target range for the ALIA 250c is 400 kilometers, and although it is designed to carry passengers, the first application of the aircraft will be for human organ transport for launch customer United Therapeutics.

Manufacture of all composite structures for the ALIA 250c is being performed by Blue Force Technologies (BFT, Morrisville, N.C., U.S.), which specializes in design, engineering, tooling, prototyping and full-rate production of composite parts and structures for the aerospace end market. Shawn Herrmann, VP Future Projects at BFT, says his team was particularly challenged by Beta Technologies, which had a number of weight and performance stipulations attached to the ALIA 250c. He says BFT was guided by three elements of the Beta design: A strict minimum structural weight fraction (of total plane weight) of 25%, highly contoured configurations with multiple structure-to-structure interfaces that require aerodynamic blending, and a highly unitized structure with minimal joints.

“Beta is going for a range design point that nobody else has ventured into, and therefore we must carry a large, efficient wing without sacrificing empty weight fraction for hover,” Herrmann says. “Every pound removed from structure can go to batteries, and thus longer range.”

50-foot wing tool for the Beta Technologies ALIA, fabricated by Blue Force Technologies. Photo Credit: Blue Force Technologies

To fabricate the first aircraft, BFT had to hit its aggressive weight target using a process that lends itself to soft tooling, without giving up significant performance versus a typical low-temperature curing standard modulus prepreg. “We have found that by using our proprietary infusion-based process,” says Herrmann, “combined with our soft-tooling approach, we can build an entire experimental [flightworthy] airframe in the same amount of time required to build carbon tooling for a prepreg-based prototype.”

Herrmann says BFT has been developing resin infusion techniques for primary structure on prototypes over the past five years. With ALIA, the company conducted further materials and process testing to iterate and enhance its infusion techniques to yield mechanical properties that would achieve the structural weight fraction required by the program. Moreover, it did this with a resin system that required only room-temperature cure and freestanding post-cure. Further, BFT endeavored to fabricate the ALIA’s structures with as few joints as possible, which means long unitized structures — including the 50-foot wing and the two 35-foot booms that hold the lifting rotors.

The resin system used to fabricate the first ALIA, says Herrmann, was developed in-house and thus is not an officially qualified material. This is adequate for prototyping, he admits, but as the ALIA enters production, certification likely will compel different materials and process decisions, including a potential shift to prepregs. “Certification will be the major driver in material selection for the production aircraft,” Herrmann says. “The production aircraft will look the same and be similar in weight, but will employ materials and processes that make sense for certification and high-rate production.”

Other considerations for full-rate production — the volume of which Beta has not disclosed — include materials and process flow, as well as automation. BFT has already begun working on the former, and the latter, says Herrmann, is almost a certainty: “Automation must yield mechanical properties used in design, must produce at the rate for which the factory was sized and at the forecast minimal recurring cost, and must be shown to be repeatable and reliable to yield laminates consistent with defect size and density assumptions made in the damage tolerance approach to certification. We see a future of rate production using various levels of automation in layup, inspection, trim/drill, assembly, etc.”

EHang’s EHang 216 is a an autonomous UAM designed to carry cargo or passengers. It features eight coaxial rotors and is fabricated by EHang’s manufacturing partner and aerocomposites specialist FACC, based in Austria. Photo Credit: EHang

EHang

Taking a slightly different tack is EHang, which is developing the EHang 216, an autonomous helicopter eVTOL designed for air taxi transport of two passengers or cargo (also called air logistics). It features eight coaxial rotors, each of which is mounted on a structural arm that extends radially from the bottom of the fuselage. The rotor arms can be folded up vertically to facilitate storage of the craft. Like Volocopter’s VoloCity (see below), the EHang 216 stands on skids. It has a maximum payload of 220 kilograms and maximum range of 35 kilometers.

Videos of the EHang 216 in flight are plentiful, demonstrating the craft’s ability as a people and cargo carrier. In May 2020, EHang was granted what the company says is the world’s first commercial pilot operation approval from the Civil Aviation Administration of China to use EHang 216 for air logistics purposes. This was followed in July 2020 by the granting of a Special Flight Operations Certificate issued by Transport Canada Civil Aviation. This will allow trial flights of EHang 216 in Québec, Canada.

EHang’s strategic manufacturing partner — including composites — for the EHang 216 is aerospace fabricator FACC AG (Ried im Innkreis, Austria). Neither EHang or FACC was willing to share composite materials or processing information with CW for this story, but FACC has reported that it will work with EHang to optimize aircraft under development and help develop plans for serial production. FACC will also help with certification, aftermarket maintenance services and research and development.

Joby Aviation

Joby Aviation’s unnamed UAM is piloted and features eight tiltrotors. Its wheeled landing gear allows it to land like a conventional aircraft or a helicopter. Photo Credit: Joby Aviation

One of the highest profile AAM programs belongs to Joby Aviation, which is developing an as-yet unnamed piloted helicopter eVTOL for air taxi transport of up to four passengers. The Joby craft is notable in that it features six tiltrotors. Two rotors are mounted on each over-fuselage wing, and there are two mounted on the tail. The craft stands on three-wheeled landing gear, has a range of 240 kilometers and a maximum speed of 320 kilometers per hour.

Joby has a multi-year commercial partnership with aerial ridesharing service Uber Elevate, but says it is also considering launching a ridesharing service of its own. In any case, the company is targeting 2023 for entry into service.

Joby would not share composites materials and process information about its aircraft with CW for this story, but it is well known that Joby has developed significant composites manufacturing operations in and near its Santa Cruz facility. John Geriguis, advanced development at Joby, said in a presentation at CAMX 2020 that Joby’s industrialization goals are similar to those outlined by Uber’s Pollack, but framed as what the company wants to avoid in its composites manufacturing operations: Little or no waste, no materials expiration, no materials out-time limits, no human resource issues, no dependence on human variables, no human inspection and no repairs after full build. Geriguis also noted that although Joby currently uses thermoset resin systems, there is opportunity for integration of thermoplastic composites in future generations of the aircraft.

Lilium’s Lilium Jet is powered by 36 ducted tiltfans. The aircraft is piloted and has room for up to four passengers. Photo Credit: Lilium

Lilium

Germany-based Lilium is developing the Lilium Jet, a piloted, fixed-wing eVTOL air taxi with seating for up to four passengers. Despite “Jet” in the name, the Lilium Jet is powered by 36 tilting ducted fans mounted on the leading edge of each wing and the horizontal tail fin. It’s designed for intercity service and has a range of 300 kilometers and a maximum speed of 300 kilometers per hour . Lilium has flight-tested the Lilium Jet, which can be viewed in a video posted on the Lilium site in October 2019. Lilium announced in July a carbon fiber supply contract with Toray (Tokyo, Japan). In the announcement, Lilium said Toray will supply carbon fiber directly to Lilium initially for use in the production of additional technology demonstrators. When the Lilium Jet enters prototyping and production, Toray will deliver carbon fiber to suppliers that will manufacture composite parts for Lilium.

Yves Yemsi, chief program officer at Lilium, says carbon fiber composites will be used in all primary structures on the Lilium Jet, including the fuselage, wings and flaps. Feedback and info promised from Lilium; has not been delivered.

The Pipistrel Nuuva A300 is a cargo-only, autonomous electric aircraft and features eight lifting rotors and one pushing rotor. Photo Credit: Pipistrel

Pipistrel

Somewhat of an outlier is Pipistrel, which is developing the Nuuva V300 autonomous eVTOL, not for passengers but for air cargo and air logistics applications. It uses eight lifting rotors and one pushing rotor and has a maximum payload of 460 kilograms. Cargo is stored within the fuselage, accessed from the side or the nose section. Pipistrel is in the midst of producing the first Nuuva V300 prototype, but the company is already taking production orders and plans to manufacture “several hundreds” per year.

Pipistrel says it has more than 25 years experience manufacturing composite aerostructures and is focusing on parts exchangeability, field repairability and quick-curing processes for the Nuuva V300. The company is using epoxy-based prepregs only, processed primarily via hand layup and room temperature cure, with occasional autoclave cure for smaller parts. Pipistrel says it expects to use out-of-autoclave, prepreg-based automation extensively when the aircraft enters production.

Volocopter’s VoloCity is an autonomous UAM that has capacity for two people. It features 18 rotors mounted on a circular frame over the fuselage. Photo Credit: Volocopter

Volocopter

The craft being developed by Volocopter, called the VoloCity, is an autonomous helicopter eVTOL with seating for two passengers. VoloCity, which uses skids instead of wheeled landing gear, is powered by 18 lifting rotors, has a maximum payload of 200 kilograms, 110 kilometers per hour maximum airspeed and a range of 35 kilometers. VoloCity’s rotors are arranged on a structural rim anchored to the top of the fuselage, with 12 rotors located equidistantly on the circumference of the rim and six more on a smaller diameter inside the rim. Each rotor has a diameter of 2.3 meters; the total diameter of the rim is 11.3 meters. Volocopter is taking reservations now for VoloCity, which it hopes will enter service by 2023.

Volocopter says it is applying composites to the entire VoloCity airframe, rotor planes and seats. Prototype and demonstrator craft are being manufactured by an unnamed composites fabricator partner using carbon fiber and glass fiber via wet layup. Resin type was not identified, but likely is epoxy. In a statement, Volocopter says it has selected a qualified fiber/resin combination because, “based on time constraints and goals, it was important to use a qualified material that suited our needs and our timeline for production.” When VoloCity enters full-rate production, Volocopter says it expects to shift to an out-of-autoclave prepreg, with fabrication provided by “international manufacturers.”

How many VoloCity craft Volocopter expects to produce annually is unknown, but statements from the company in response to information requests for this story suggest “thousands,” adding that, “What is certain though is that we are looking to achieve production rates closer to those of car manufacturers than those of aircraft manufacturers currently.”

Wisk’s Cora is an autonomous UAM with room for two passengers. It features 12 lifting rotors and one pushing rotor. Wisk is a joint venture of Boeing and Kitty Hawk. Photo Credit: Wisk

Wisk

Wisk, a joint venture of Boeing (Seattle, Wash., U.S.) and Kitty Hawk (Palo Alto, Calif., U.S.), is developing the Cora, an autonomous, fixed-wing eVTOL air taxi with seating for two passengers. Cora is powered by 12 lifting rotors — three located forward and aft of each wing — and one pushing rotor located at the aft end of the fuselage in front of the tail section. The plane stand on three wheeled landing gear. Cora has a maximum range of 40 kilometers and a maximum speed of 160 kilometers per hour.

Wisk says all primary structures on Cora are fabricated in-house with composites using a proprietary combination of resin and fibers. In a statement, Wisk said qualified materials were chosen because “it is generally easier to start design from an already proven solution.” The manufacturing process is laser-guided hand layup with out-of-autoclave consolidation under vacuum bag. Finished structures are assessed with limit load testing, thermography and ultrasonic inspection. As production ramps up, the company expects to integrate automation technologies to meet “production rates that are currently envisioned for eVTOLs.” Wisk also says it expects to maintain in-house manufacturing when Cora enters full rate production, with contractors providing supplementary production as capacity constraints dictate.

|

Table 1: UAM Manufacturers, Aircraft |

|||||

|

Manufacturer/craft |

Propulsion |

Control |

Capacity |

Max. range |

Max. speed |

|

Beta Technologies’ ALIA  |

4 lift rotors, 1 push rotor |

1 pilot |

5 passengers |

400 km |

274 kph |

|

EHang EHang 216  |

16 rotors (8 pairs) |

Autonomous |

2 passengers or 220 kg |

35 km |

130 kph |

|

Joby (unnamed)  |

6 tiltrotors |

1 pilot |

4 passengers |

240 km |

320 kph |

|

Lilium Lilium Jet  |

36 ducted tiltfans |

1 pilot |

4 passengers |

300 km |

300 kph |

|

Pipistrel Nuuva V300  |

8 lift rotors, 1 push rotor |

Autonomous |

460 kg (cargo) |

300 km |

220 kph |

|

Volocopter VoloCity  |

18 rotors |

Autonomous |

2 passengers or 200 kg |

35 km |

110 kph |

|

Wisk Cora  |

12 lift rotors, 1 push rotor |

Autonomous |

2 passengers or 180 kg |

40 km |

160 kph |

Related Content

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreNext-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More