No business case for teaching robots

The German Aerospace Center (DLR) developed a flexible automation platform for this work cell to build families of CFRP aerostructures that use the same process — dry noncrimp fabric, pick-and-place layup and resin infusion — to fabricate products like rear pressure bulkheads and fuselage panels. Collaborative robots are not taught, but instead define their own collision-free paths for picking and placing cut plies into a tool based on CAD and process definition inputs and AI algorithms. Such AI-driven automation is one basis for future smart Composites 4.0 factories.

Source | (top) DLR Institute for Structures and Design, (bottom) ©KUKA AG

Composites 4.0 is one small galaxy in the universe of Industry 4.0, which is the digital transformation in how goods and services are designed, produced, delivered, operated, maintained and decommissioned. For composites manufacturing, the goal is to use automation, sensors and data, 5G communications, software and other continuously evolving digital technologies to make products and processes more efficient, intelligent and adaptive.

Composites manufacturers are proceeding through this digital transformation along a spectrum. Initial steps include inline inspection and optimized processes that reduce waste and cost while increasing part quality and yield. More advanced solutions work toward intelligent, autonomous production that is not just agile, but responds to and even anticipates changing markets and customer demands.

“Composites 4.0 is not an end, but a tool,” explains Dr. Michael Emonts, managing director of the AZL Aachen Center for Integrative Lightweight Production at RWTH Aachen University (Aachen, Germany), whose iComposite 4.0 project demonstrated an adaptive process chain with potential to reduce an automotive floor pan cost by 50-64%.

“There is a difference between just making things digital and digital transformation that actually changes the processes behind your business and opens new opportunities and business models,” contends Christian Koppenberg, managing director for composite parts producer Dynexa (Laudenbach, Germany).

“Composites 4.0 is not just using robots,” asserts Dr. Michael Kupke, head of the German Aerospace Center’s (DLR) Center for Lightweight Production Technology (ZLP, Augsburg), which has developed an artificial intelligence [AI]-equipped work cell where collaborative robots can switch from producing composite rear pressure bulkheads to fuselage panels without reprogramming or retraining. “It is the technology that ensures you don’t have to teach the robots, because there is no business case for that. Composites 4.0 is more than just increasing efficiency and cutting cost. It is a change in how companies think about and approach production that will determine which companies survive and which do not.”

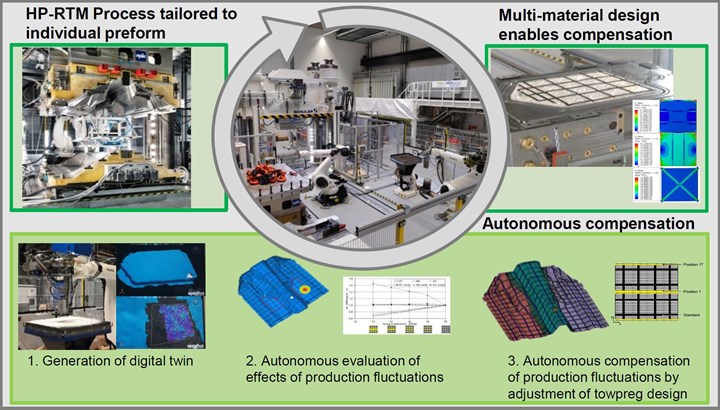

Adaptive preforming, RTM

“The idea of the iComposite 4.0 project was to create preforms from cost-effective rovings and tows by combining dry, long glass fiber (25-30 millimeters) sprayed and subsequently reinforced with a grid of unidirectional (UD) carbon fibers via automated fiber placement (AFP),” explains Emonts. “The chosen demonstrator, a rear under vehicle floor pan, was previously made with more costly textiles which also produced more than 60% waste.”

The Composites 4.0 transformation required integration of the fiber spraying, fiber deposition and subsequent resin transfer molding (RTM) processes so that they reacted to each other and adapted based on the part quality measured between steps (Fig. 1). “We used a machine vision system from Apodius GmbH [Aachen, Germany] with an optical laser sensor and a camera module to characterize the surface topology of the sprayed preform,” says Emonts. “Apodius adapted the software to analyze the percentage of fibers in each direction. The iComposite 4.0 line compared this to the digital design and decided if it met the mechanical requirements. If yes, it applied the standard UD grid for reinforcement. If no, it decided where to place additional UD fiber layers.”

Fig. 1. iComposite 4.0 adaptive process

This AZL Aachen led-project combined 3D fiber spraying, automated UD tape laying and RTM into an adaptive process chain. Automation allowed the processes to react to each other based

on preform quality, which is assessed by an optical laser between steps. Source | AZL Aachen

However, these additional UD layers could cause part thickness and geometry to exceed tolerances. “Therefore,” he explains, “we combined the preforming line with an adaptive RTM process which, if necessary, adjusted the part thickness by increasing pressure on certain parts of the press.” This too was automated, with the aim to replace intervention from the line operator, but it did require simulation of part performance using measurement data and standard FEA software.

“Currently, simulation of the part mechanical properties is performed offline,” says Emonts. “We generated a database of process and part variations, created algorithms to react to each variation and validated these via FEA. Thus, based on the variations measured by the line, the algorithms directed it to perform an appropriate mitigation. To make the line adaptive in-situ, the next step would be to add machine learning.” Meanwhile, AZL is pursuing numerous Composite 4.0 projects including self-optimized production of hybrid thermoplastic composites and injection molded parts with integrated stiffening of tape-based tailored blanks.

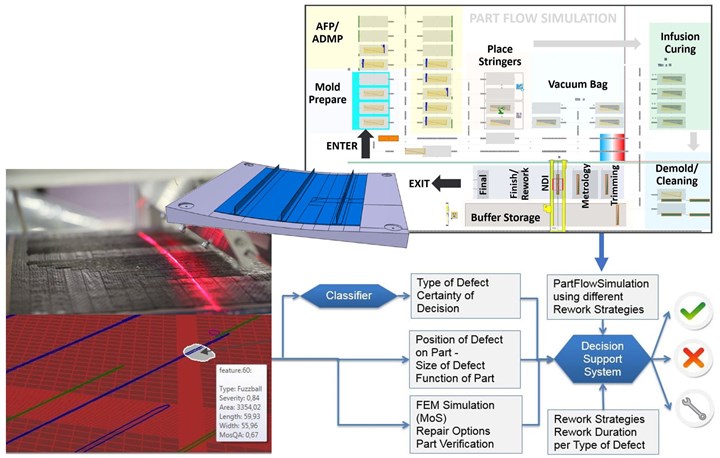

Zero-defect CFRP wingskins

The ZAero project (see “Zero-defect manufacturing of composite parts”) is another key Composites 4.0 project, that started in 2016. It aimed to increase productivity for large carbon fiber-reinforced plastic (CFRP) structures such as wingskins. Defects would be reduced by using automated inline inspection with either prepreg AFP or Danobat’s (Elgoibar, Spain) automated dry material placement (ADMP, see “Proving viability of dry fabrics, infusion for large aerostructures”). Process monitoring during resin infusion or prepreg cure would predict state of cure and shorten cycle time. Collected process and defect data were used with FEA to predict part performance. This was then input into a decision support tool for how to address identified defects. A part flow simulation for CFRP wingskins was developed that, when fed into this tool, helped to optimize a rework strategy (Fig. 2). Today, many such parts are reworked during manufacturing, but only after NDI. Earlier rework and improved process control were indeed goals of the ZAero project, as well as enablers for its targeted 15% increase in production rate, 15-20% reduction in production cost and 50% less waste.

Fig. 2. Zero-defect wingskins

The ZAero project demonstrated inline defect control for CFRP-stiffened panels. Shown from top left, counterclockwise: integrated laser sensor for AFP, defect classification, flow chart showing combination with FEA modeling of part performance and a decision support tool as well as part flow simulation for CFRP wing skins (top right) to optimize strategies for rework.

Source | Profactor

By the September 2019 final review, the prepreg AFP sensor developed by project leader Profactor (Steyr, Austria) not only achieved automated inline inspection, but could also be used to correct parts in-situ. “This sensor can detect the standard defects such as gaps, overlaps, FOD, fuzzballs and twisted tows, as well as early and late cut of each tow,” says Dr. Christian Eitzinger, head of machine vision for Profactor. A missing tow can be corrected automatically with the placement of an additional tow precisely where it was omitted. The machine must be stopped, however, to remove fuzzballs or a twisted tow. “A database built using Dassault Systèmes’ (Paris, France) 3D Experience for CATIA allows us to calculate the effects on the part’s performance based on the size, shape and type of defect. Processing all defects in a ply takes only seconds. The machine operator then decides what defects can be left and what must be reworked.”

For infusion process monitoring and control, Airbus (Toulouse, France) worked through subsidiary InFactory Solutions (Taufkirchen, Germany) to develop three sensors that measure temperature, state of cure and resin flow front (see “Sensors for monitoring resin infusion flow front”.) “We have integrated these with CATIA 3D Experience and shown that the data can be reliably acquired and added to each part’s digital thread,” says Eitzinger. (See online sidebar “Composites 4.0: Digital thread vs. digital twin”.)

The final of three part demonstrators was an upper wing cover subsection with three stringers (see online sidebar “ZAero project update”). For this part, Profactor’s decision support tool was demonstrated live at partner FIDAMC (Madrid, Spain), connected to the part flow simulation — based on Siemens PLM (Plano, Texas, U.S.) Tecnomatix Plant Simulation software — running on Profactor’s server in Austria. In addition to building a defect database, ZAero conducted experiments with machine learning. Manually designed, generative computer models combined with deep neural networks detected and classified defects, achieving a rate of 95% correct classification of different regions (gap, overlap, tow, fuzzball) in real ADMP monitoring data, even when artificially created defect data was used for the deep network training (analogous to how ultrasonic testing systems are calibrated on a range of deliberate defects).

“We will definitely pursue some kind of next phase,” says Eitzinger. Meanwhile, Profactor is commercializing modular sensors for fiber orientation and defects during automated layup. InFactory Solutions is also offering its AFP and resin infusion sensors, and fiber placement partners Danobat and MTorres (Torres de Elorz, Navarra, Spain) are now selling their equipment with integrated inline inspection.

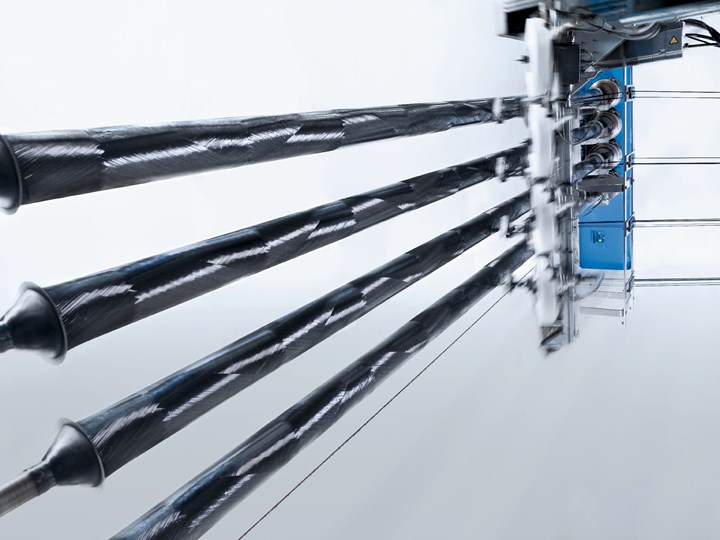

Dynexa’s digital transformation journey

Dynexa is a composite parts manufacturer specializing in CFRP tubes and shafts. “We had always tried to digitize everything,” says managing director Koppenberg. “We already got rid of manual and analog processes, integrating everything mostly into our ERP [enterprise resource planning] system. But how do we do this in manufacturing? We understood that everything we put into a worker protocol or procedure is a code, and this is a basis for digital transformation. But where is it stored? On a local server, in the cloud or within the machine? We would ask five people and get seven answers as to what we should do.” (See online sidebar, “Composites 4.0: Where to start?”)

Fortunately, the German government had set up a program for universities to provide free Industry 4.0 consulting for small and medium enterprises (SMEs). Dynexa began work with the Darmstadt “Mittelstand (SME) 4.0” Competence Center. “They said not to worry about the digital architecture but look more to what you need to measure and how to do that,” recalls Koppenberg. “We picked one process that involved significant manual measuring, where we knew we had quality, time and cost issues.”

Fig. 3. Digital transformation first steps

Working with the Darmstadt SME 4.0 Competence Center, Dynexa developed a digital camera system to monitor tube/shaft thickness and automatically adjust resin pick up (bottom) during filament winding (top), eliminating manual measurement and improving efficiency and cost. Source | Dynexa

Dynexa uses a wet filament winding process.(see “Composite output shaft ready for automotive proving ground.)” A key step is resin pick up, where the dry fiber is run onto a compaction roller which rolls up out of the resin bath. Sitting against the compaction roller is a doctor blade which determines the amount of resin to be combined with the dry filament before it’s wound. “If we pick up too much resin, we may exceed the specified tube diameter,” says Koppenberg, “but with too little resin, we risk falling below the minimum diameter allowed.”

“Without measuring, you only know the final diameter after cure, when all of the value has been invested,” he points out. “So, the operator must stop the machine, measure the part, write it down and then restart. From years of experience, we know what the laminate thickness should be at each stage of winding. Thus, the operator compares the measurement and adjusts the doctor blade to correct resin pick up as necessary, but this is very manual and relies on operator skill and experience.”

To digitize this, Dynexa talked to myriad laser and camera manufacturers. “They would say, ‘we have the solution’ but then no one could make it work,” notes Koppenberg. The University of Darmstadt team, however, enabled use of a camera by figuring out the corrections needed due to certain physical factors, such as light reflection from the wet surface. “Now, we have the winding machine connected to the measuring device, which operates in a very standardized way,” he adds.

The team developed a database of correction tables and decision algorithms which enables the filament winding machine to know what the target needs to be for each stage of the specific tube being wound. “If the measuring device input shows that the resin pick up is not where it should be,” explains Koppenberg, “the filament winding machine responds by adjusting the doctor blade to bring it back into spec without stopping winding to measure.”

Every winding machine now has the digital measuring system, and an ethernet card. “The most expensive part was installing and running the cables to the server,” quips Koppenberg, “but now we can talk to every machine and collect all the data.” And there is another benefit. “Before, operators were programming at the machines, but once we connected them to the server, we can program at any desktop or laptop computer. This has further reduced downtime and removed another production bottleneck.”

This first digital step has allowed Dynexa to improve its process control, quality and efficiency, allowing it to become more cost effective. It has also spurred further transformation.

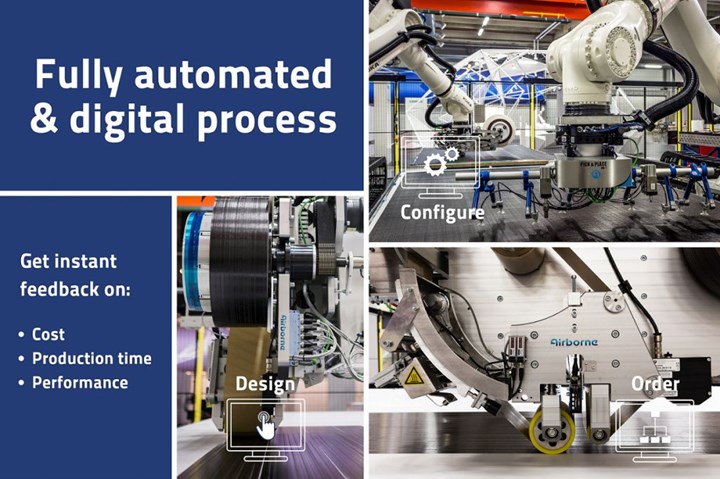

Changing paradigms for composites

“We are in a stepwise process of providing a new ecosystem for our customers,” says Matthias Bruckhoff, Dynexa’s head of sales and marketing. He gives an example: “In Amazon, you can see what you have bought and when, as well as suggested new products. We used to take customer requirements and then respond in a few days using our calculations and engineering tools. Now, this will be online. Our customers will look at products and calculate what they need, cost and delivery in a matter of minutes. This is not new, but it is for our industry. Just as we freed up our machine operators to focus on more machines and higher-level tasks, we will now free up our engineering team to focus on more specialized and sophisticated products.”

Fig. 4. On-demand Manufacturing Portal

Airborne launched its online portal for composites in 2019 (top) where customers enter designs and receive cost and estimated delivery for laminates/parts made by Airborne’s automated manufacturing cells, including, in a future extension, the Falcon high-volume thermoplastic composites line developed for SABIC (bottom). Source | Airborne

Airborne (The Hague, Netherlands) launched its On-demand Manufacturing Portal for automated manufacturing of composites in September 2019 (see “Airborne launches composite printing portal”). Using this tool, customers enter designs into the web-based platform. The system then creates the machine code on the fly and determines the production duration and cost. Products can then be customized and, once ordered, produced in an automated manufacturing cell. The portal was launched using Airborne’s Automated Laminating Cell (ALC) to process thermoset prepreg. It will be extended to other processes, for example, the high-volume thermoplastic composites (TPC) production line developed for SABIC’s (Riyadh, Saudi Arabia) Specialties business unit.

“This portal is a key building block of how we see the digital future of composite manufacturing,” says Marcus Kremers, chief technology officer at Airborne. “Five years ago, we changed from a parts manufacturing business model to helping customers with automation and digitization. We are developing a portfolio of solutions that make it easy for customers to build with composites.” This portfolio includes the ALC, automated honeycomb potting, automated ply kitting and the high-volume line using TPC tapes, dubbed the Digital Composites Manufacturing Line (DCML) by SABIC and Falcon by Airborne. The latter is an example of Airborne’s bespoke solutions. “We are embedding our composites materials and parts manufacturing knowledge into these automated systems so that the customers don’t have to be specialists,” says Kremers.

Airborne has three business models: buy the automation, rent it or leave it with Airborne to operate via manufacturing as a service (MaaS). Airborne automated cells have sensors and inline inspection systems that generate alerts based on a database of defects and tolerances defined by the customer. “The Falcon line has very low tolerances for visual quality defects,” Kremers notes, “but our automation for aerospace is more driven by structural tolerances. We are also continuously advancing our technologies to be self-learning and self-adaptive. For example, our next software version for ALC tape laying will have the ability to identify defects and amend the production program on the fly.”

Longer term, the vision is to expand the on-demand portal to collect composite parts production capacity distributed across multiple companies and regions. Kremers cites Protolabs (Maple Plains, Minn., U.S.), which provides injection molded, sheet metal, CNC machined or 3D-printed protoypes on-demand in as little as a day. Similarly, Plyable’s (Oxford, U.K.) online app provides molds to manufacture composites, offering materials ranging from polyurethane board to steel, including composite and 3D-printed tools. “That is a different way to organize the value chain,” says Kremers. “We are making the machines and software that will make this possible for composite parts.”

AZL Aachen is also pursuing this goal with its Ultra-Fast Consolidator Machine, developed to produce multi-layer TPC laminates in less than five seconds. Commercialized in 2019, it uses Conbility (Aachen, Germany) robotic, laser-assisted AFP applicators and 25-millimeter wide UD tapes as well as a piece-flow principle — state-of-the-art in the high-speed printing industry — to produce TPC laminates, simply tacked or fully consolidated, in a variety of thicknesses, with local reinforcements. “Our vision is to provide scalable machines that will enable online platforms,” says Emonts. “Lines can have multiple stations, each with multiple AFP applicators. The customer will enter the requirements and get options for plybook, cost and delivery. Once finalized, the applicators communicate to each other to organize production, not the operator. This is completely intelligent production of tailored composites.”

Automating the automation

The ZLP’s main focus is automated production of CFRP structures. “Automation for just one part or program is hard to justify,” notes Florian Krebs, ZLP team leader for flexible automation. “However, if you move beyond task-specific machines to an automation platform that is reconfigurable with almost no additional setup, now you have a business solution. The more flexible the platform, the quicker the return on investment.”

The work cell shown in the opening images was designed as part of the ZLP project PROTEC NSR to build a family of parts that follows the same process route: pick-and-place layup of dry noncrimp fabrics and resin infusion (see online sidebar “No business case for teaching robots”). “This process was designed for the Airbus A350 rear pressure bulkhead, but you could also make a fuselage panel or a wing cover on this line because the steps are similar,” says Krebs.

“To achieve flexible automation platforms requires certain technology bricks, including algorithms for the robots, as well as sensors and how to understand the data they produce,” says Kupke. “For example, the PROTEC NSR production line is designed toward maximum modularity — all modules interconnected to each other to demonstrate a self-configuring, -correction and -optimizing system, scalable in size and complexity.”

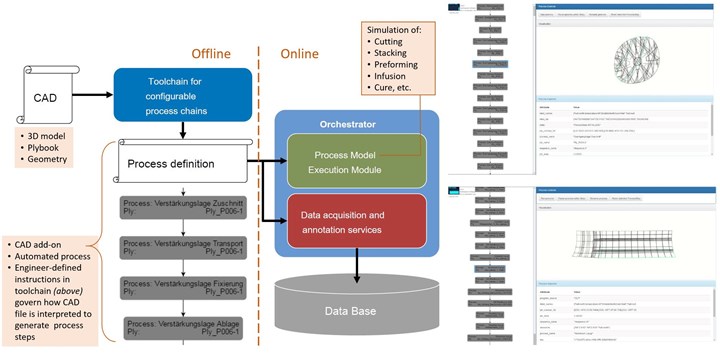

Fig. 5. Digital structure for flexible, intelligent automation

For the PROTEC NSR project, ZLP developed a flexible automation platform that can produce a CFRP rear pressure bulkhead (top right) or fuselage panel (bottom right), and switch between these quickly by simply changing the CAD file. Engineer-defined instructions in the toolchain (dark blue box) govern how to interpret the CAD data to automatically generate new process steps.

Source | DLR Institute for Structures and Design

He explains the modules as shown in Fig. 5, which include CAD model, process definition, process model that allows simulation and execution of the process, manufacturing execution module, sensors to acquire data, software to annotate the data and database for storage.

“On the left side of this diagram, you make a plan. The execution module then implements that plan,” says Kupke. “During the process steps, we acquire data from all involved machines and processes, for example, the cutter, the robots, the building (temperature, pressure, humidity), the cameras during pick-and-place, etc. We analyze the data in real-time during the process and also annotate the collected data automatically with meta-data to feed it into the database, which forms the basis for the digital twin of the process. The most important point of the digital twin is to have one central repository, one source of truth. Each part’s CAD model and process definition are part of its single source of truth.”

With these modules in place, the line operates autonomously with the push of a button. From the CAD model, production plan and cameras, the robots infer which cut piece comes next and look for it on the table (e.g., from 100 other cut pieces). “They decide how to configure the grippers to pick it up and lay it in the tooling, and know where to place it.” Based on the production plan, the robots determine each start/end path for all of the process steps and know when each is done. “Usually, these paths are taught by a human,” notes Kupke. “But in our system, each path is defined automatically, collision-free and in real time. If you change the CAD model or the process definition, then the robots will adapt without any additional teaching effort. But what if you change the part completely? With this type of automation, you could make that change very quickly. This is the route to flexible production. Our role at ZLP is to pave this route by developing technology bricks and linking them together.”

Opportunity and ontology

The COVID-19 pandemic has highlighted the value of flexible production. It also has created an increasingly unpredictable business environment. “In the last two to three years, everything has gotten more volatile,” notes Dynexa's Bruckhoff. “Our customers want answers very fast, in order to respond to their customer. By offering our new online ecosystem, we make the whole supply chain more competitive.”

This is well-recognized by the aviation industry. “We need a digital basis for production lines and whole sites that enables both horizontal and vertical integration,” says Marc Fette, chairman of the Technical Division Aerospace Technologies of the VDI – The German Association for Engineers and COO for Composite Technology Center (CTC, Stade, Germany), an R&T subsidiary of Airbus. CTC projects in Composites 4.0 include material and asset tracking, collaborative robots, advanced process chains and more. But Fette stresses the need for ontology — a terminology and common protocol for digital communication and data exchange. (See the online sidebar “Composites 4.0 architecture and ontology”.)

“You need a holistic networking for all the machines and production systems in a given plant,” he explains, “but this must also extend to the entire value-creation chain, including disciplines such as engineering, procurement, logistics and materials and process certification, on the one hand. On the other hand, all stakeholders, such as suppliers, have to be considered and involved in this change process. We see a lot of pilot projects, but when you look in detail, there is still a lack of strategy for a holistic approach per company or production chain.”

He continues: “We have a very large, global network of suppliers and they have the same requirements in order to operate as a digitally connected supply chain. Most of our suppliers are SMEs working for both aircraft manufacturers, Airbus and Boeing. If there is no discussion about a common standard, then you pass these challenges on to the suppliers. They most likely cannot afford to comply with two sets of differing standards for all of their machines, including documentation, assessing data, cyber security, etc.”

Fette concedes these are big ideas and says that aircraft OEMs are creating plans to address these challenges. “But there are many obstacles like this, and it’s really complex, involving not just technology but social, economic, ergonomic and legal issues — it’s a change process mentally. We are just at the beginning. But to succeed, we must understand that these new systems rely on people and these people must be on board, not just at OEMs, but in the whole global network.”

“Markets are becoming more fragmented across all industries and everyone is facing a paradigm shift,” notes ZLP’s Krebs. “Many people don’t see that as an opportunity,” adds Kupke, also of ZLP. But those who do see that opportunity envision democratized access to composites enabled by Composites 4.0, and with that, a much broader market, including applications that we are only beginning to conceive.

Related Content

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreCo-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

Read MoreAngeloni launches non-stitched multiaxial NCF fabric option

An adhesive grants the same stability of traditionally stitched composite fabrics, making Stratos suitable for use in a range of fibers and production processes.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)