Composites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

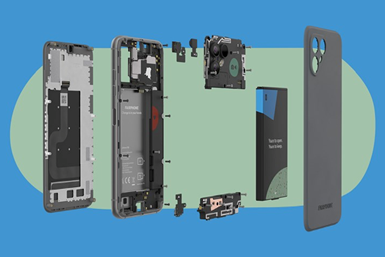

A new smartphone launched in 2022 by startup Carbon Mobile GmbH features what is said to be the industry’s lightest, thinnest design, thanks to a CFRTP composite shell that better protects electronics while making the device easier to repair and recycle compared to legacy designs. Other notable innovations include overcoming carbon fiber’s tendency to block radio frequency (RF) signals while also enabling isotropic grounding and electrostatic discharge (ESD) solutions, and designing the device to reduce environmental impact. Source | Carbon Mobile GmbH

Composite materials play an important role in the design and manufacturing of consumer electronics, lending such qualities as light weight, durability and aesthetics for various devices. Composites also offer design flexibility, enabling manufacturers to create sleek and ergonomic parts and accessories for devices like smartphones and wearables. In addition, composites can be engineered to have improved thermal conductivity, aiding in the efficient dissipation of heat generated by electronic components. Glass fiber-reinforced polymers (GFRP), which provide electrical insulation, are often used for insulation purposes in electronic devices and are widely used in printed circuit boards (PCB), the structures that connect electronic components to each other in most devices.

As consumer trends in electronics have progressed, demand for increasingly lighter, durable devices continues to rise. While GFRP remains widely used, the use of carbon fiber increases. Known for their exceptional strength-to-weight ratio, carbon fiber is increasingly being turned to for its strength and lightness in applications such as covers for smartphones, laptops or smartwatches. Carbon fiber also enhances the durability of electronic devices, ensuring resistance to impact and wear.

In recent years, research and development initiatives, along with prototype demonstrations, have demonstrated composites to be viable substitutes for metals. This shift has enabled the production of radio-transparent device components that are not only lighter and more durable but also align with sustainability goals. Particularly, the emphasis on the sustainability and recyclability of thermoplastic composites has significantly heightened the appeal of these materials to consumers.

Innovations in RF, heat dissipation

Cutting-edge advancements in materials within the electronics market are frequently driving new developments and carbon fiber-reinforced thermoplastic polymer (CFRTP) composites have emerged as a forefront innovation in this dynamic landscape.

In June 2022, Arris (Berkley, Calif., U.S.), known for its additive molding process, published a study it conducted to analyze the radio frequency (RF) response of glass fiber and carbon fiber composites in a smartphone cover design. The findings demonstrated a smartphone cover that is both lighter and stiffer, while still preserving the essential RF levels necessary for effective communication between the phone’s electronic components and antennas and cell towers.

In 2022, CW also reported on a research project conducted by several Japanese universities using cellulose nanofiber as a filler with a composite component to help solve challenges with effective heat dissipation within electronic components. The nanofiber films that were created are also said to be recyclable at the product’s end of life (EOL).

In March 2023, Carbon Mobile (Berlin, Germany), a startup company that develops radio-enabled carbon fiber composites in electronics devices, and chemicals company SABIC (Riyadh, Saudi Arabia), announced a collaboration to drive industry-wide adoption of next-gen, advanced carbon fiber composites in smart devices. The collaboration enables Carbon Mobile to leverage SABIC’s range of materials, including the company’s Trucircle portfolio of materials designed for recyclability.

Carbon Mobile is known for its patented HyRECM technology, which produces a robust carbon fiber composite monocoque housing structure for a very thin and light smartphone, with the least amount of material used as possible. To further boost the device’s connectivity, a conductive ink trace is integrated into the carbon fiber structure to stabilize the electrical and wireless properties. In 2001, the technology was featured on Carbon Mobile’s Carbon 1 MKII smartphone. The device features a CFTRP cover supplied by Lanxess (Cologne, Germany), and is manufactured using Carbon Mobile’s patented process. The advantages of this case include its lightweight, durability and radiolucency. Additionally, the fully thermoplastic shell facilitates easy disassembly and recycling when the product reaches its EOL.

In addition, in 2023 SABIC also launched a new glass fiber-reinforced LNP Thermocomp WF006V compound, which is well-suited for laser direct structuring (LDS) of antennas that are integrated into the housings and covers of consumer electronics devices, appliances and other electronic components.

Recyclability in electronics

The Fairphone 4, with a glass fiber-reinforced center frame, made in part with recycled materials from Covestro. Source | Fairphone

As alluded to above, environmental responsibility, sustainability considerations and a growing use of recycled materials play an increasingly important role in the manufacture of electronics.

In 2023, Swancor (Nantou, Taiwan) introduced EzCiclo low-dielectric epoxy hardener tailored for copper-clad laminates (CCL), enabling the use of recycled waste plastics in printed circuit board (PCB) production.

And in 2022, Dutch smartphone company Fairphone (Amsterdam, Netherlands) began using a Covestro (Leverkusen, Germany; Shanghai, China) product line of post-consumer recycled polycarbonate and thermoplastic polyurethanes (TPU) in smartphone case components. Covestro’s Maezio brand of continuous CFRTP composites, which come in tape or sheet form, have been used in smartphone cases as well as a variety of other consumer applications.

Evolution in energy sources

Innovation in electronics also extends to new energy sources and storage applications offering more efficient and sustaible ways to power devices.

In 2023, researchers from the Institute of Thin Films, Sensors and Imaging (ITFSI) from the University of the West of Scotland (UWS, Paisley) explored the use of the 3D graphene foam material Gii by Integrated Graphene (Stirling, U.K.) as an active layer in an energy generator known as a triboelectric nanogenerator (TENG). The project is aimed at transforming mechanical energy wasted in nature into electrical energy that could be used to power small electronic devices and sensors.

In addition, a new type of composite material studied by the University of California, Riverside in 2023 offers unique properties defined by quantum condensate effects, presenting new approaches to energy storage. These quantum composites revealed an unusually high dielectric constant — more than two orders of magnitude enhancement — while remaining electrically insulating, thus offering potential for a range of innovative applications related to variable capacitors, capacitive sensors, capacitors for energy storage and reflective coatings.

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreRead Next

Composites end markets: Sports and recreation (2024)

Light weight and high performance continue to make composites popular in the elite sporting good market. Sustainability in both materials and recycling solutions are a key innovation area.

Read MoreComposites end markets: Industrial (2024)

The use of composites in industrial applications is increasing, driven by the need for higher performance and longer life, whether its parts for industrial machinery, EOAT components, corrosion-resistant equipment and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More