Developing milling for CMC because grinding takes too long

Economical processes that can cut machining time by 70% are being tested on aeroengine turbine blade demonstrators by Hufschmied and DLR in the SCANCUT project.

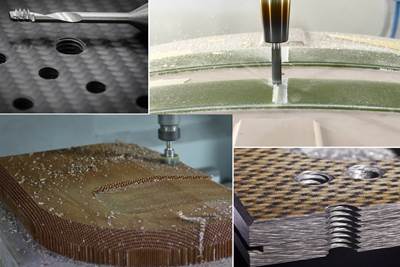

Traditionally turbine blades in aircraft engines have been metal (left). Now, ceramic matrix composite (CMC) versions are being explored (right) enabling higher temperatures and lower weight for more efficient engines. A cutting tool developed by Hufschmied (bottom left) offers an optimized micro-geometry specialized for CMC machining needs.

Extreme heat and strong temperature fluctuations pose major challenges for materials in aircraft engines. In order to increase the efficiency and effectiveness of engines, the trend is toward ever-higher operating temperatures. Ceramic materials in particular, which have excellent high-temperature properties, offer the potential for improved temperature resistance. Monolithic ceramics, though, are brittle, and thus not suitable as structural components. However, by adding fiber reinforcement to a ceramic matrix — i.e., ceramic matrix composites (CMC) — damage-tolerant properties are possible. Silicon carbide (SiC/SiC) CMC developed at the German Aerospace Center (DLR, Augsburg) can currently withstand uncooled continuous loads of up to 1250°C, with potential for even higher temperatures. In addition, the lower density of these materials offers the possibility to further reduce aircraft engine weight and thus increase thrust-to-weight ratio for improved efficiency, necessary for aviation’s decarbonization.

One goal has been to use CMC to replace metal turbine blades in aircraft engines. But this has been repeatedly postponed for several reasons, including the lack of efficient production processes and machining/postprocessing of the CMC blanks required for tight-tolerance blades. DLR and Hufschmied Zerspanungssysteme GmbH (Bobingen, Germany), with its U.S. subsidiary Hufschmied Tools Corp. (HZS), collaborated with the Augsburg University of Applied Sciences (Augsburg, Germany) in the SCANCUT project to develop new manufacturing technologies for CMC turbine components.

Hufschmied is known in the industry for process optimization of CFRP and GFRP composites machining and already has experience working with machining SiC/SiC. In 2018, together with a manufacturer of CMC materials, it succeeded in replacing a grinding process with milling for SiC/SiC bearing sleeves that reduced the overall machining time by around 70%. As a partner in the DLR-funded SCANCUT project, Hufschmied has taken another step forward.

CMC properties demand a new approach

The desired properties of CMC are also those that make machining and postprocessing so difficult. Fiber-reinforced ceramics have high temperature resistance and high rigidity combined with high toughness, while the SiC fibers give the material a quasi-ductile behavior. Near-net-shape components also require postprocessing in order to produce smooth surfaces and achieve the tightest possible tolerances. Thus, CMC has mostly been machined by grinding instead of cutting because the extremely high hardness and heat resistance of SiC lead to a very high load on the cutting edge of milling tools.

Traditionally, such situations would be addressed by using diamond-coated tools. With CMC, this was previously not possible because the diamond coating would flake off after a short time. In the 2018 project, Hufschmied therefore developed a polycrystalline diamond (PCD) milling tool specifically for the SiC/SiC bearing sleeves. But is this the only option?

PCD tools are expensive and complex to manufacture. Thus, this material is more commonly used for cutting inserts. At Hufschmied, the geometries of the cutting edges have always been one of the factors used to achieve the greatest improvements in machining. However, PCD offers limited possibilities for this. So, a new approach was needed.

Test series with dummy material

Work in the SCANCUT project was performed using a more commonly available and less expensive CMC made with carbon fiber reinforcement in a carbon/SiC matrix known as C/C-SiC. In addition to making the test series affordable, it was found that the behavior of C/C-SiC hardly differs from that of SiC/SiC. Thus, testing began at the Hufschmied Technology Center in Bobingen, south of Augsburg, with the aim to find an alternative to PCD in order to produce complex surfaces on CMC blanks more cost-effectively. “Compared to PCD tools, diamond-coated solid carbide tools allow greater freedom of geometry at reduced costs,” says Macken, “provided that a way can be found to avoid the potential for uncontrolled wear of coated tools.”

Trial, error and breakthrough

Note, a new standard tool for machining CMC is not yet available to buy. However, development has reached a stage where it is clear that efficient machining with diamond-coated solid carbide tools is possible. To continue to push this technology forward, Hufschmied carried out a series of tests with four different tool variants. Three aspects were varied, and their interactions examined: cutting edge geometry, coating technology and cutting parameters.

A close-up of the newly developed cutting tool. Source | Hufschmied Zerspanungssysteme

When it came to the tool cutting edge geometry, the developers initially focused only on the micro-geometry of the cutting edge. Issues such as the number of cutting edges or the macro-geometry were left out for the time being and will be explored in planned follow-up projects. The second aspect investigated was the coating. Hufschmied has developed numerous solutions for particularly abrasive materials (e.g., CFRP, GFRP, graphite) and has already patented its own microcrystalline diamond coating. Thus, it experimented with variants of this technology in order to test whether a durable coating can be developed for CMC. The third aspect — and this is essential for any machining optimization — was the variation of the cutting parameters. Experiments were carried out with infeeds between 0.05-1 millimeter, feed per tooth between 0.01-0.2 millimeter and spindle speeds between 1,000-20,000 revolutions/minute.

With a newly developed micro-geometry and a diamond coating optimized for CMC, it was then possible to develop a cutting tool prototype that showed controlled wear behavior. This means that the coating wears gradually but does not chip off when confronted with the fiber-reinforced ceramic, as is the case with conventional diamond-coated tools.

“Based on this initial success, we will continue to develop and test until we have made our contribution to the triumphant advance of CMC in the aerospace industry and beyond,” explains Christel Hufschmied, managing director of Hufschmied Machining Systems. “We’ve made a start and now it’s time to compare the tool life of the new tools with that of PCD tools. The closer those are, the more economically interesting our new approach will be.”

About the Author

Joshua Macken

Joshua Macken has been a development engineer at Hufschmied Zerspanungssysteme GmbH (Bobingen, Germany) since September 2023. In 2019, he graduated from Munich University of Applied Sciences in applied research in engineering sciences (M. Sc.)., and for 3 years was a research assistant at the THA studying the machining of CMC materials. In his current role at Hufschmied, Macken’s main topics of interest include machining of ceramic and CMC materials, process monitoring and digitalization.

Related Content

MATECH C/ZrOC composite is deployed in hypersonic aeroshells

Ultra high-temperature insulating CMC targets hypersonics, space heat shields and other demanding applications, tested up to 2760°C under extreme stagnation pressures.

Read MoreGeneral Atomics wins DOE contract to develop silicon carbide CMC for fusion power plants

GA-EMS will leverage experience with SiGA SiC/SiC cladding for nuclear fuel rods to develop new SiC composite foam and other materials for fission and magnetic fusion programs.

Read MoreORNL, Sierra Space create novel C/SiC TPS for reusable space vehicles

CMC tiles will be used on the Sierra Space DC100 Dream Chaser spaceplane carrying critical supplies and science experiments to and from NASA’s ISS.

Read MoreDITF Denkendorf advances sustainable carbon fibers, oxide fibers for CMC and more

The German Institutes of Textile and Fiber Research are targeting more sustainable carbon fiber via low-pressure stabilization and bio-based precursors, and working with Saint-Gobain to commercialize oxide ceramic fibers for CMC.

Read MoreRead Next

Optimizing, customizing composites hole drilling

Matching the drill tool to the job can save thousands of man-hours and millions of dollars.

Read MoreOptimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read More

.jpeg;maxWidth=150;quality=70)

.jpg;maxWidth=300;quality=90)

.jpeg;maxWidth=400;quality=70)