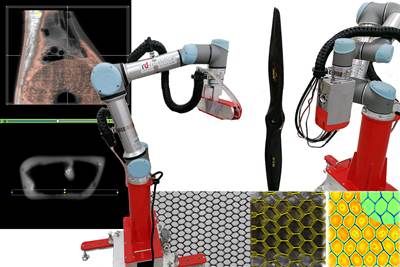

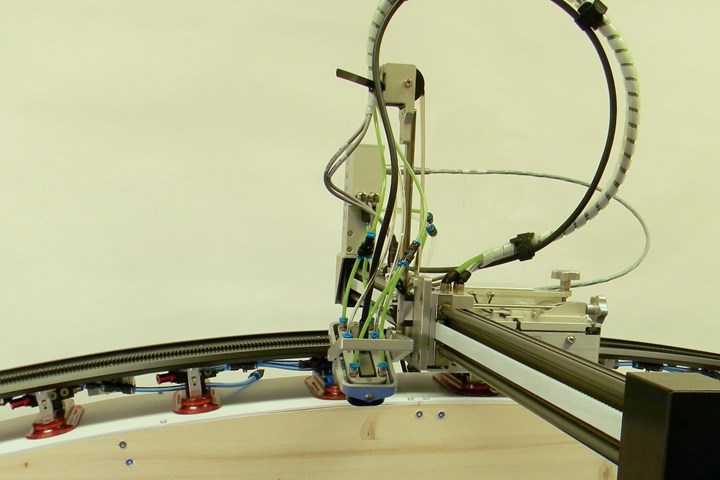

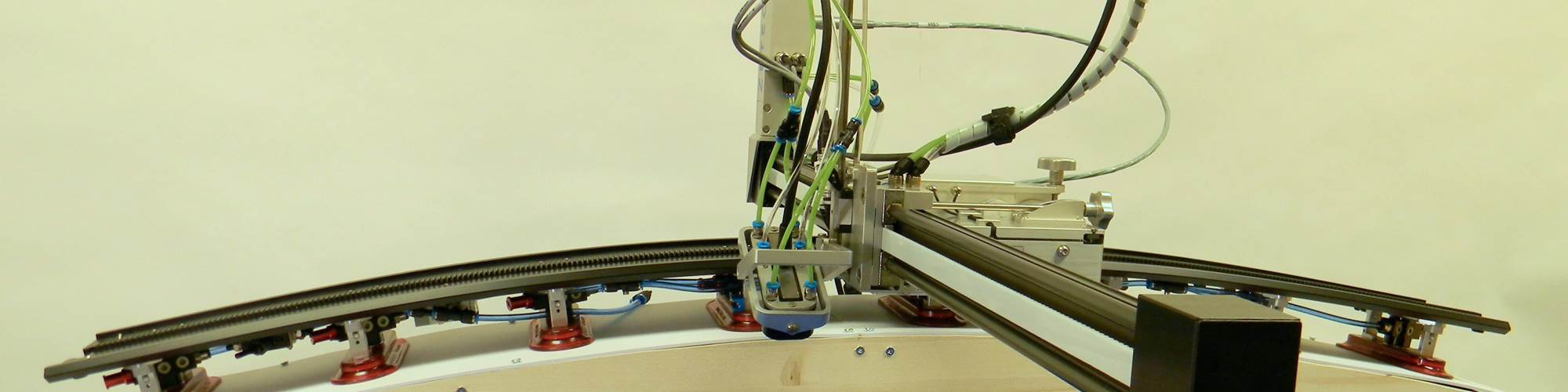

A scanner ensures that ultrasonic probes stay properly aligned as they move over the surface of the inspection area. Scanners with motorized actuator arms, suction cups and adjustable, flexible tracks are ideal for ultrasonic inspections of large surface areas with complex geometries. Photo Credit, all images: Zetec Inc.

In aerospace manufacturing and maintenance, repair and overhaul (MRO), there are many nondestructive testing (NDT) techniques for aluminum and steel, but far fewer options for carbon and glass fiber-reinforced polymer (CFRP, GFRP) composites.

Given the multi-layered, anisotropic nature of these materials, flaws like cracks, porosity and foreign bodies can occur on the surface or within a particular layer of fiber or resin with no predictable orientation. Delamination defects can propagate quickly, especially in components where a laminate is loaded through the thickness. There may be little or no warning between the points of fatigue and catastrophic failure, which is of critical importance in aerospace and other industries that value the strength-to-weight ratio of composites.

As NDT technologies evolve, ultrasound has proven to be an effective way to determine the depth and size of flaws in composite materials.

What is ultrasound?

Ultrasonic testing (UT) uses pulses of high-frequency sound energy emitted into the material by a transducer or probe. The probe transmits ultrasonic waves at precise intervals and a set angle. When a wave encounters a defect, some of that energy is reflected back like an echo. The time it takes for that energy to reach the probe is calculated, analyzed and presented as an image on a screen for the technician to view.

Conventional ultrasound, using single-element transducers, is limited by high attenuation and low signal-to-noise ratio (SNR). Phased array ultrasonic testing (PAUT) uses multiple independent elements (typically 16-64) in a single probe to generate high-quality guided signals that can travel longer distances and cover more area. This helps speed inspections and make them more thorough, which is especially important on large components with complex geometries.

Instrumentation

PAUT encompasses a system of hardware and software that works together to acquire and process inspection data into meaningful results.

Powerful, portable phased array UT instruments are one of the most important developments in non-destructive testing of composites. Their processing power and compact size make it possible to deliver accurate inspection results whether you’re on the flight line or in the factory. This image is of one such instrument offered by Zetec, the TOPAZ64 PAUT.

At the center of this system is a powerful, compact and portable PAUT instrument that can perform sophisticated testing in the field or at the factory.

These instruments have features like 64-channel code-compliant PAUT and the ability to capture and store all time-domain signals (A-scans) from every transmitter-receiver pair of elements in the array, a technique called full matrix capture (FMC). FMC allows the “full matrix” of raw A-scan signals to be processed in real time, or saved for offline processing using different sets of reconstruction parameters for any given focal law or beam (aperture, angle or focus depth).

Having access to the raw signal information opens the door to advanced algorithms like the total focusing method (TFM), which uses FMC data to produce high-resolution 2D and 3D images for defect characterization and sizing; time of flight diffraction (TOFD) capabilities; and plane wave imaging (PWI) data acquisition.

Software

As computing power evolves, so does inspection software. Software can manage the entire inspection process including probe design (acoustic beam simulation), inspection technique development and validation, high-speed data acquisition, advanced data analysis and comprehensive reporting.

Software can also add flexibility in the inspection process. For instance, on a component with curves or variable thicknesses, maintaining the proper probe orientation typically involves sophisticated and therefore expensive mechanical systems and exact knowledge of the specimen geometry. Software can enable adaptive UT inspection techniques like time reversal, which can compensate for the effects of misalignment between the probe and the specimen in real time.

Software development kits (SDK) allow users to integrate their own development to create custom solutions such as specific UI, processing and analysis tools, custom processed data, remote interaction with an inspection management system and real-time streaming of data to another software platform.

Composites are a challenging application for NDT. As their use expands, the demand for more capable inspection systems continues to build. For manufacturers, MRO managers and NDT service providers faced with complicated tasks like testing composite materials, that means using instruments and software that excel when combined together, in terms of performance, speed and cost effectiveness.

About the Author

Daniel Richard

Daniel Richard is technology manager at Zetec (Snoqualmie, Wash., U.S.), which develops ultrasonic and other NDT solutions for rail, oil and gas, aerospace, and other industries. He is based in Quebec City, Canada.

Related Content

NDT inspection services, automated systems serve aerospace needs

CAMX 2023: Arcadia Aerospace Industries demonstrates its commitment to navigating the rapidly changing aerospace manufacturing landscape with robotic-based machines and motion control systems, certified facilities for NDT services and conducted training and recruitment.

Read MoreMachine, equipment investment strengthens Ruckus Composites’ research, innovation

CNC services expansion, universal testing machines and advanced inspection enable Ruckus to delve deeper into the study and evaluation of carbon fiber damage, as well as nondestructive and destructive testing.

Read MoreLaser NDT, DIC systems demonstrate optimized noncontact composites inspection

CAMX 2024: Dantec Dynamics is presenting three of its laser shearography NDT and DIC devices, geared toward reliable measurement results.

Read MoreLoop Technology develops robotic arm for wing box inspection

Part of an R&D project with Spirit AeroSystems, the seven-axis Bravura robotic arm automates inspection and sealing within small spaces like aircraft wing boxes.

Read MoreRead Next

Contact-less microsensor targets real-time NDT for composite structures

RVmagnetics’ MicroWire self-monitors composite structures via embedding during the production process. It improves safety, control and real-time data for predictive maintenance.

Read MoreCurtiss-Wright and Dolphitech team up on predictive wind turbine maintenance service

Combination of StressWave, PdP Pattern Recognition software with Dolphicam2 ultrasonic inspection for CFRP structures to provide end-to-end solution for damage detection, prevention and prediction.

Read MoreRobotic computed tomography – removing NDT barriers for composites

Radalytica uses collaborative robots, ultra-sensitive X-ray photon detectors and the ability to combine CT with ultrasound, surface profiling and other inspection methods to optimize composites part quality, production and reduce cost.

Read More

.jpg;maxWidth=300;quality=90)