KCARBON and KIST develop lyocell/PLA/wood biocomposites

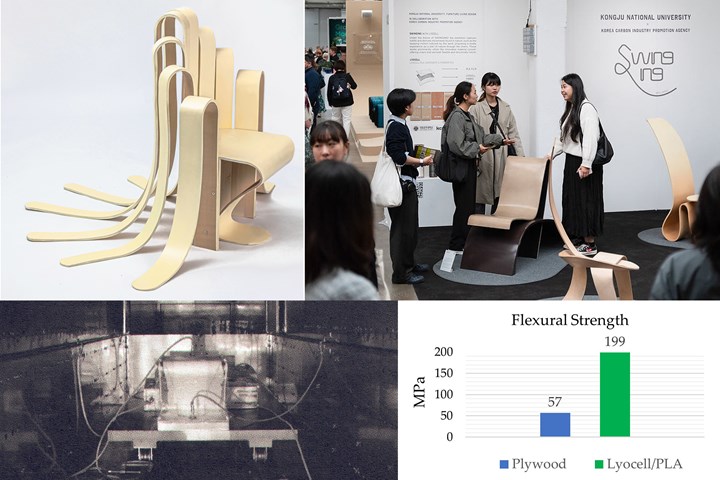

Initial demonstration in furniture shows properties two to nine times higher than plywood, OOA molding for uniquely shaped components.

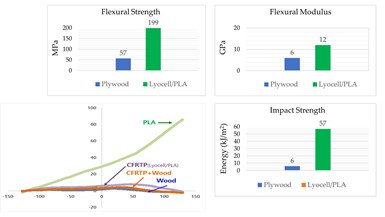

Biocomposites comprise fiber reinforcement and matrix materials that are derived from renewable, natural and, typically, biodegradable materials. Interest in biocomposites is growing because they offer the potential for improved sustainability, including eco-friendly processing and end-of-life options. Biocomposites comprising lyocell fiber, polylactic acid (PLA) and wood have been developed by Korea Carbon Industry Promotion Agency (KCARBON, Jeonju-si, South Korea) in partnership with the Korea Institute Science Technology (KIST, Seoul, South Korea). Testing of these materials showed flexural strength, flexural modulus and impact strength that are three, two and nine times higher, respectively, than plywood. In a first demonstration of these materials, KCARBON worked with Kongju National University (Gongju-si, South Korea) to develop furniture which was displayed at the 2023 London Design Fair (London, U.K.). KCARBON continues to advance composition, processing and applications for biocomposites.

Promoting carbon as a strategic material

The history of KCARBON goes back many years, including establishing a carbon fiber production system in 2007, followed by a joint technology development agreement with Hyosung (Seoul, South Korea), which is now scaling to be one of the top carbon fiber suppliers in the world. A carbon technology institute was opened in 2009 and a carbon fiber raw material (precursor) production system installed in 2011. This was also the year that the Carbon Valley in Korea was established and in the following years, multiple agreements were signed with well-known carbon fiber and composites institutions such as the AMRC and NCC (U.K.), JEC in Europe, MAI and CFK Valley and Aachen University (Germany), RISE SICOMP (Sweden) and ICC (Japan). Additional capabilities were installed in the following year, including a:

- Small and Medium Business Startup Incubation Center

- Carbon Technology Education Center

- Carbon Composite Molding Technology Center

- Carbon Composite Commercialization Technology Center

- Carbon Composite New Product Development Support Center

Designated as part of the Jeonju Carbon Materials Specialty Complex, KCARBON was then formed in 2021 with the mission to promote and strengthen all forms of carbon as a future material, including not only carbon fiber, but also graphite, graphene and carbon nanotube/nanomaterials, as well as activated carbon for electrically conductive applications and carbon black for filtration and super capacitor technologies.

At CAMX 2023, KCARBON exhibited its leadership in carbon fiber recycling (left) and carbon fiber in hydrogen storage tanks (right). Photo Credit: CW

“Our institute’s scope of work is very wide,” notes Dr. Kyusoon Park, division head for KCARBON. “Our job is to create programs that support companies and industry to develop these materials with a special focus on technology transfer. We also work in fundamental research and applications-oriented R&D.” With 170 employees, mostly researchers and technicians, KCARBON is currently managing six promotion programs and 60 research/R&D programs — 60% of which involve carbon fiber. Topics range from carbon fiber-reinforced composites used in hydrogen storage to recycling to improving the basic properties of carbon fiber such as tensile strength and modulus. KCARBON has also set up the infrastructure to complete lifecycle assessment (LCA) for carbon fiber and composites and is invested in developing more sustainable composites, including the work summarized here.

Composition of lyocell/PLA/wood composites

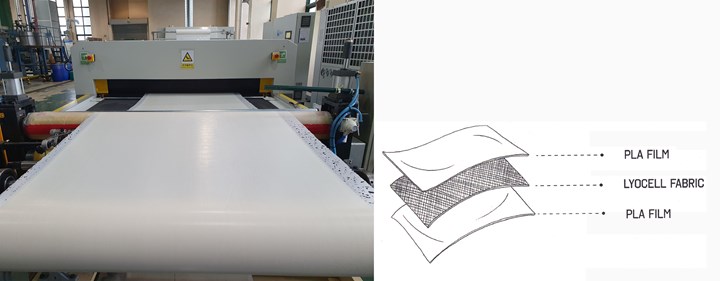

Lyocell fiber (left) was woven and laminated with PLA film (center) to form a thermoplastic prepreg (right).

Lyocell is a continuous fiber derived from wood pulp. It is produced with recycled and environmentally friendly solvents and then spun into endless fibers, which distinguishes it from length-limited natural fibers such as flax and hemp. Noted for its sustainability, strength and durability, lyocell does absorb moisture readily, but this also helps it to biodegrade, which it does in just 30 days under composting conditions.

To help protect the lyocell fiber and prevent water absorption, PLA is used as a matrix. PLA is a thermoplastic monomer made from lactic acid created through fermentation of renewable plant material such as corn, sugar cane, sugar beet pulp or cassava. PLA is also biodegradable and has been certified as industrially compostable.

Wood was the third ingredient chosen for this initial demonstration. As the original natural composite — cellulose fibers held together by the biopolymer lignin — wood is strong, durable and workable, offering a warm and natural aesthetic and feel. It is also inherently workable, able to be bent and formed into shapes, especially when used as thin veneers or plies. However, wood is also vulnerable to water and can suffer from inconsistency and irregularity as a natural material.

Manufacturing of lyocell/PLA/wood composites

A laminating machine was used to fuse the lyocell fabric between two plies of PLA film (top). This prepreg was then plied with wood veneers, hand laid onto a mold (bottom left) and thermoformed in an oven (bottom right).

The KCARBON/KIST research team used continuous lyocell fiber from Hyosung woven into a 0.12-millimeter-thick textile with an areal weight of 173 grams/square meter. This was then impregnated with Luminy LX175 PLA supplied by TotalEnergies Corbion (Gorinchem, Netherlands) as a 0.36-millimeter-thick film. The lyocell textile was sandwiched between two PLA films and processed through a laminating machine to form a thermoplastic 0.48-millimeter-thick prepreg with roughly 50% fiber volume.

The lyocell/PLA prepreg was then stacked in alternating layers with thin plies of birch veneer. For each shaped furniture element, a mold made from medium density fiberboard (MDF) was created. Plies of lyocell/PLA prepreg and wood veneer were hand laid onto the mold and then vacuum bagged before heating in a 2 × 2 × 14-meter oven to 180°C for 3 hours. Molded elements were then assembled using woodworking joints, bonding and/or fasteners.

Testing showed the lyocell/PLA/wood composites outperform plywood in flexural strength and modulus and impact strength while offering similar thermal deflection to wood (CFRTP = continuous fiber-reinforced thermoplastic).

Mechanical testing was also performed on standardized coupons of lyocell/PLA/wood composites using the test methods ASTM D790 for flexural properties, ASTM D648 for heat deflection temperature (HDT) and ISO 179 for Charpy impact strength. As stated above, the biocomposite shows much higher flexural strength and modulus as well as impact strength versus plywood. HDT testing showed the biocomposite has a similar thermal deflection to that of wood across a wide spectrum of temperatures.

Future development

KCARBON and KIST continue to explore biocomposites, including development of induction heating to reduce energy use during molding.

KCARBON and KIST are interested not only in the continued development and maturation of biocomposites but also in new manufacturing processes, including the potential use of induction heating in tools that could reduce energy use during molding by up to 75% as well as cycle time compared to existing oven and autoclave processes.

Summarized from: “Sustainable Innovation of High-Performance Bio-Composites: Continuous Lyocell, PLA and Wood Composites”

by Yunhyuk Bang1, Sangjun Yun2, Geonyeong Park1, Seojeong Jeong1, Sohyun Kim3, Henry Hyunkyu Shin1

1 – KCARBON (Korea Carbon Industry Promotion Agency)

2 – KIST (Korea Institute Science of Technology)

3 – Dept. of Furniture Living Design, Kongju National University

For more details, contact Henry Shin.

Related Content

Microwave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MorePlant tour: Arris Composites, Berkeley, Calif., U.S.

The creator of Additive Molding is leveraging automation and thermoplastics to provide high-volume, high-quality, sustainable composites manufacturing services.

Read MoreWatch: A practical view of sustainability in composites product development

Markus Beer of Forward Engineering addresses definitions of sustainability, how to approach sustainability goals, the role of life cycle analysis (LCA) and social, environmental and governmental driving forces. Watch his “CW Tech Days: Sustainability” presentation.

Read MoreRead Next

Biocomposite for mobile architecture, low load-bearing applications

The German Institutes of Textile and Fiber Research and partners have developed a biocomposite well suited for support profiles and connecting nodes in construction applications.

Read MoreDITF researches lignin-based protective coating for natural fiber geotextiles

The bio-based coating was applied to yarns and textile surfaces to extend service life with positive results, suggesting its future application in civil engineering.

Read More

.jpg;maxWidth=300;quality=90)