Mold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

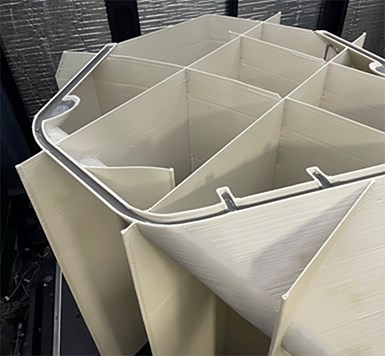

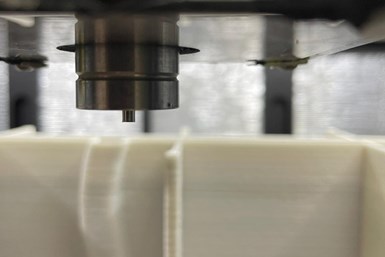

Aiming to combat labor shortages, Lyons Industries has been gradually installing automated processes to replace the traditionally labor-intensive spray-up process for its fiberglass composite bathtubs and showers. Photo credit: Lyons Industries (top image), Massivit (bottom image)

Lyons Industries Inc. (Dowagiac, Mich., U.S.) is a family-owned manufacturer of fiberglass composite bathtubs and showers that has been in business for more than 50 years. Lance Lyons, the company’s president, says that more than 1,000 pieces are produced per day at the 135,000-square-foot facility.

The manufacture of these bathtubs and showers is a vacuum forming and spray-up process. First, a sheet of acrylic plastic is heated in an oven and then stretched over an epoxy female mold for the specific product being produced. The mold is loaded into the vacuum former, and vacuum is pulled, causing the plastic to form onto the mold’s shape. After cooling, these plastic parts — called shells — are loaded onto a support fixture and moved into a spray booth, where they are sprayed with chopped fiberglass and resin. Parts are then cured in a large industrial oven — Lyons calls this a “heat tunnel” — and cooled, trimmed and packaged.

Traditionally, much of this work is manual, but Lyons explains that over the past several years, the company has been slowly increasing its reliance on automation to combat labor shortages while at the same time increasing the quality and consistency of the final product. This has included a semi-automated cart moving system and robotic loaders to transfer parts from station to station, two fiberglass spraying robots, robotic waterjet cutters and a Massivit (Lod, Israel) 10000 industrial 3D printer for additively manufacturing molds and support fixtures.

Lyons says that creating tooling and support fixtures is one of the longest and most labor-intensive parts of the process, so the company began investigating 3D printing systems to directly print high-quality molds and support fixtures.

The Massivit 3D printing system installed at Lyons Industries’ partner Prestige Tooling in Elkhart, Ind., U.S. The two companies work together to design and manufacture molds and support mixtures using the Massivit system. Photo Credit: Lyons Industries

Lyons Industries ultimately decided to acquire a Massivit 10000 system, which operates via a four-step process. First, based on an initial CAD design, the mold or fixture is printed using two printheads: the first printhead deposits a water-breakable thermoset polymer to create a sacrificial shell layer on the outside, and a second printhead prints the actual mold with a high-performance epoxy called CIM 500 inside the shell. This material offers a consistent and low coefficient of thermal expansion (CTE) at high temperatures and results in a truly isotropic mold. Second, the overall printed structure is cured in an oven. Third, the structure is immersed in a tub of plain water, where the outer shell breaks off. Finally, the resulting mold can be finished and ready for use.

It was decided that this system would be located at partner company Prestige Tooling’s (Elkhart, Ind., U.S.) facility, which has built molds for Lyons Industries for many years. Lyons adds that automation is not a simple, one-time investment. “You can’t just install a 3D printer, robots or saws. You need to also upgrade electrical systems, infrastructure, computers and software. It’s a process.”

The Massivit system prints the mold in two layers: an outer, sacrificial layer in a thermoset polymer that acts as a supportive layer during printing and will break off when submerged in water, and the inner mold made with a high-performance epoxy. The pictured support fixture is for manufacturing a 60 × 32 × 19-inch bathtub. Photo Credit: Lyons Industries (upper image), Massivit (lower image)

Once everything was in place, the Massivit system was installed at Prestige in fall 2022 and began operation by the end of the year. Lyons explains, “We’ve taken the crawl, walk, run approach. We started with support fixtures for our shower bases, which are 4-5 feet long, 2-3 feet wide, but only about an inch or two thick. Once we figured that out, we started working on our first bathtub support fixtures, which are also about 5 feet long and about 2 feet wide, but almost 16 inches deep.”

These relatively small fixtures could be printed in one piece, but moving on to larger and more complex parts like bathtub molds requires printing in two pieces. “The beauty of being able to print the way [Massivit does] is it’s like actually printing interlocking puzzle pieces together,” Lyons notes. “And then there’s some sanding and finish work involved, but nothing like the old process. We’ve been refining the process and making bigger and bigger parts.”

He adds, “It’s an obvious solution for moldmaking, because instead of making a pattern and then casting the mold off that pattern, you just go straight to making the mold or support fixture for production.” The digitization of the 3D printing process also helps to ensure consistent quality.

“What would have taken us about 16 weeks we can do in 3-4 weeks now, with a fraction of the manpower,” Lyons says. “We’re able to make a better product faster for our customers, and it’s an easier process for our employees.”

Related Content

Norco GFRP molds meet high-quality cast concrete beam production needs

A project with P&M successfully achieved manufacture of six 20-meter-long architectural beams for an R&D facility with near-seamless surfaces and on a tight production schedule.

Read MorePlant tour: Airtech International, Springfield, Tenn., U.S.

Fifty years of supplying materials for composites manufacturing includes custom fabrication and now aims to advance 3D-printed tooling, parts and new resins.

Read MoreCorebon induction heating

This sidebar to CW’s August 2024 feature article reviews this technology for more efficient composites manufacturing and why it aligns with Koridion active core molding.

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreRead Next

ORNL conducts sustainability analysis of 3D-printed composite molds

A comprehensive lifecycle, cost and carbon emissions study on carbon fiber molds, produced for New York’s concrete Domino building, cites economic benefits over wood alternatives.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)