Optimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

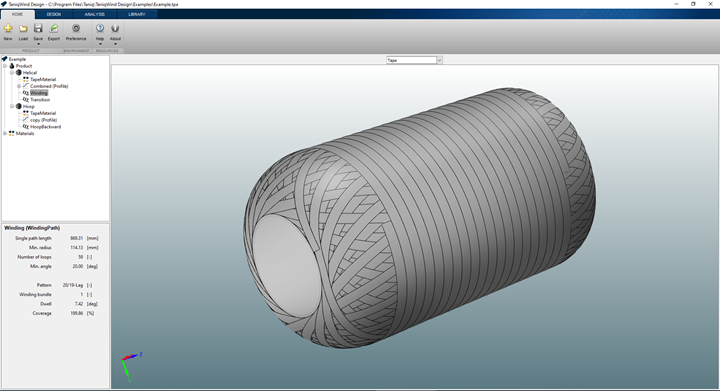

TANIQ (Rotterdam, Netherlands) released its TaniqWind pressure vessel design and filament winding software in 2022 and presented its latest TaniqWind Pro at JEC World 2024 (March 5-7, Paris, France). The company is part of the Netherlands liquid hydrogen (LH2) consortium, led by Toray Advanced Composites (TAC, Nijverdal, Netherlands), which began a 45-month project in 2021 to demonstrate LH2 composite tanks for civil aviation (see “Demonstrating composite LH2 tanks for commercial aircraft”). For this consortium, TANIQ is contributing its software and robotic winding expertise.

TANIQ also recently finished a 3-year project developing composite H2 pressure vessels with Fraunhofer Institute for Production Technology (IPT, Aachen, Germany) using laser-assisted tape winding (LATW) of thermoplastic composites (TPC). It assisted with the project’s composite pressure vessel design and with integrating functionalities for control of critical parameters during the tape winding process.

Robotic filament winding, specialty rubber composites

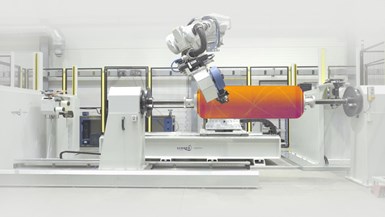

TANIQ has developed robotic winding systems integrating fibers, metal wires, rubber and wrapping tapes (top) for specialty reinforced rubber hoses and pressure vessels (middle and bottom). Source | TANIQ

TANIQ was founded in 2006 as a spin-off from the Aerospace Dept. at the Delft University of Technology in the Netherlands. “We started as one of the first companies in the world to use an industrial robot arm for filament winding,” says Soren Blomaard, director and co-founder of TANIQ. “Robotic winding back then was quite new. Although we had the engineering background from the aerospace and composite structures group, we actually decided to go first into a rather niche market of rubber composites. This is a big market where rubber products have all kinds of reinforcement structures inside — the most commonly known is tires, which use nylon cords and metal wires. There are also a lot of specialty products such as automotive hoses, air springs, automotive air bags/rescue bags, marine hoses and oil hoses. For such applications, we took our knowledge of how to optimally reinforce typical hoses or pressure vessels and applied that to these specialty reinforced rubber applications.”

“We found that using a robot to do the placement would give the highest accuracy and also the possibility to further automate these processes,” says Blomaard. “Once we implemented the reinforcement paths, we started adding the rubber to the process. Uncured rubber is challenging to handle and it took us several years to develop dedicated winding tools and the control strategy to manage this process. Still today, we are improving our systems to also process very soft and gum-like materials like silicone rubber. To complete the automated winding of all materials in typical rubber composites, we added solutions for special wrapping tapes and metal wires. We could not only optimize the design of these products but also automatically manufacture them.” He notes an automotive tire is made every 30-60 seconds. “It's a continuous, repetitive and very fast process.”

TANIQ’s clients have mainly been in specialty applications, with products typically built on steel or segmented mandrels, which can take hours and sometimes days to manufacture. “For example, we make expansion joints for nuclear power plants and submarines,” says Blomaard. “These joints are the rubber compensators between metal piping systems, and each one has a different specification including length and burst pressure, which makes the process difficult to automate. The engineering is also labor intensive.” This type of application where automation is very challenging is TANIQ’s focus. “The combination of our software and robotics provides a flexible automation solution that makes this possible,” says Blomaard.

“We've been doing this for about 15 years, and had moved away completely from regular composites,” he continues. “And then around 2018, we got more and more requests from companies asking if they could use our robotic winding systems and design software for more typical pressure vessels. It was just when hydrogen development was starting to pick up speed. And we realized that what we had been developing for design and automation of these rubber composites was also a solution for composite pressure vessels. At the same time a leading filament winding software company was bought off the market, creating a market opening for new software. It was good timing for us to move into the composites industry. ”

Software and equipment for composite pressure vessels

TANIQ started collaborating with universities and research institutes to explore how its technology could be used with more traditional composites. “The whole theory that we use for designing hoses is pressure vessel theory,” says Blomaard. “The fibers take all the load, and you have a matrix material to contain the liquid or the gas, so designing a rubber pressure vessel is actually quite similar to a composite pressure vessel; but there are also big differences.”

TANIQ released TaniqWind software in 2022, based on its expertise in robotic winding and advanced pressure vessel design. Source | TANIQ

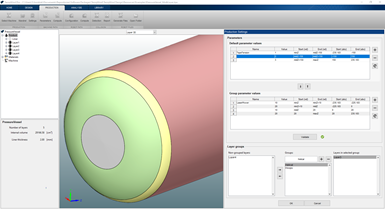

In 2022, TANIQ released its TaniqWind software for filament winding composite pressure vessels. It was the same in-house developed software that the company had already been using for a long time, but with some key upgrades. “We included all kinds of improvements and functionalities so that the user can very easily do certain steps in the design process,” says Blomaard. “We worked together with Altair Engineering [Troy, Mich., U.S.] for one year to create a custom FEA export functionality for their multi-scale modeling approach, which makes it very efficient to design a pressure vessel, do the analysis in an FEA package and then iterate between the two to further optimize. We already have about 20 users of the software. In TaniqWind Pro, we have further extended the FEA capabilities to now support shell, 2DA and 3D elements for both HyperWorks and Abaqus.”

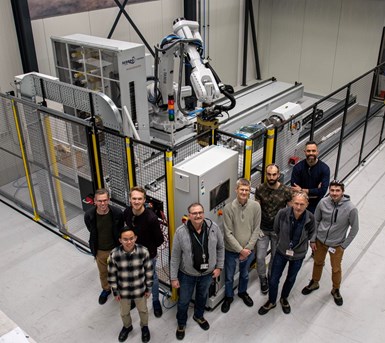

The composites team of GKN Fokker (Hoogeveen, The Netherlands) in front of their new filament winding robot supplied by TANIQ. Source | GKN Fokker

At the same time, TANIQ continued its developments with several companies and institutes, such as Fraunhofer IPT and the Netherlands LH2 consortium. “We also sold the first integrated solution of robotic equipment with TaniqWind Pro software to GKN Fokker (Hoogeveen, Netherlands),” says Blomaard, “for manufacturing of missile cannisters and composite pressure vessels. Our expertise has really been in robotic winding and that is why we developed this advanced design software. We initially focused on the winding software, but we learned that there is as much interest for our robotic winding systems — thus, we have a unique position to provide this integrated software and robotic solution. We're quite happy with the progress we’ve made in composite pressure vessels in such a short time, and that is partly driven by all the companies that are working on hydrogen storage and looking for solutions.”

Optimizing storage efficiency, improving digital models

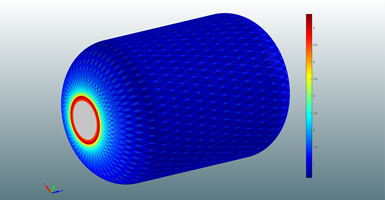

How much improvement in the storage efficiency of the tank is possible with design optimization using advanced software such as TaniqWind? “We think the focus first should be on the reliability of the design and its manufacturability,” says Blomaard. “In the pre-design phase, software can be used to quickly design composite layers and to analyze and optimize performance using FEA Software. These tools are very suitable for the pre-design phase, but not for manufacturing.”

“Since these composite layers are simplified,” he continues, “they are not 1:1 manufacturable — the exact design parameters cannot be translated into actual winding programs. This means that new layers need to be designed for production, and these will deviate (slightly) from the modelled design. Also, the prediction of build-up defining the local layer thickness often doesn’t correspond with the actual build-up profile, especially not for tapes. This means that the material is placed on a different profile, resulting in a different build-up than modelled, which sometimes results in issues with sliding fibers or misalignment of the tape winding tool. Therefore, with our TaniqWind Pro software, we focus on two things:

- Design for manufacturability considering all physical criteria of the winding process

- Optimizing the thickness buildup calculations.

“We have been working to look at all existing buildup models for winding tanks and the differences between dry winding and wet winding of filaments versus winding of TPC tapes. And this will create different buildup behaviors. We already made some improvements to other software as we have integrated different theories and polynomial approximations for both material groups in our software, but I think for the coming 2-3 years, there's so much more to gain there. You can model all you want, but if the input for your model doesn’t represent the tank you're actually going to build, then you cannot make those final improvements that are needed for higher storage efficiency and lighter weight.”

TaniqWind Pro software has a powerful FEA toolbox for generating FE models for shell, 2DA and 3D elements for Hyperworks and Abaqus — and allows users to preview and optimize the mesh quality within the software. Source | TANIQ

“And it's not only the buildups and transition areas, but also the void factors and compaction in certain areas,” he continues. “I think if we are better able to predict those, then our designs will be more realistic which then means that the FEA models will be more reliable, and the winding programs can be first time right. At the moment, I think the accuracy of production is already relatively good, but it could be improved even more. However, there's more to win in having a reliable design, especially for thick-walled pressure vessels and in those critical areas that I discussed.”

“The pull from the market to have more efficient pressure vessels, and to reduce the cost of the carbon fiber in the pressure vessel was not previously as big as it is today,” Blomaard points out. “We are collaborating in developments where we are actually trying to measure, in production, every layer and every profile contour, and to feed that back into our software to actually see how these buildups are changing and to make it more accurate.”

Using sensors?

What about using sensors to help validate the FEA models? “We collaborated in a project with Com&Sens (Eke, Belgium), where they placed their optical fiber in the pressure vessel to measure the processing stress in the fiber, and afterwards in testing to measure stress concentrations while the vessel was pressurized,” says Blomaard. “It was used to measure stresses in different areas of the vessel during winding. This means you have different compaction so that the void factors will be different in different zones of the pressure vessel. It was also used to measure the stresses throughout the layers during pressurization. That's interesting to measure, but you still have to do something with the data. How can you translate that for better design of the next pressure vessel? When you know that some layers are activated to their maximum stress level, while other layers are hardly activated and therefore not contributing, you can adjust, for example, the layup design, or play with pretension of layers to optimize the construction as a whole.”

Winding TPC tanks

In the project TANIQ completed with Fraunhofer IPT to explore TPC pressure vessels, Blomaard says the Fraunhofer team was mainly interested in applying the right amount of heat to the tape at any point of the LATW trajectory. “The challenge was that the winding speed varies along the profile, reaching lowest speeds at the turnaround zones at the domes,” he explains. “This requires the laser power to be adjusted per section to prevent under/over heating. And our job was to help integrate control of the LATW process parameters into the winding software. Initially, Fraunhofer would make a winding program for the robot, and then manually add values for the laser intensity to individual points of the machine path. We added a functionality in the software where they can set variable process values (laser power, roller compression, tape tension) per layer, or per section within a layer. Being able to control these variables from the software is a huge improvement in terms of reliability and efficiency.”

In the same project, TANIQ also worked with Pixargus (Würselen, Germany) which provides industrial systems for measuring defects during carbon fiber tape production. “They can optically measure surface defects, which they can also then process so that you can do inline or offline analysis,” notes Blomaard. “For this project with Fraunhofer IPT, Pixargus developed a kind of scanner that was integrated into the tape winding system. During winding, we could measure all kinds of defects on the tape surface and categorize those defects by severity of the damage and then also link each defect to a point in the product. So, we could know which defects were located where in the product. And then when those pressure vessels were tested, we could see if there was actually failure happening around those defects.”

“This project was on a relatively small scale — 10 prototypes — but it's still very interesting because already we have seen quite a large variety in the quality of tapes,” he continues. “Having this capability to continuously measure the tape quality and help decide if the effects are too much is important. You can actually stop the process and intervene, take that tank out of production or pull that material from production.”

TaniqWind Pro software allows users to define variable process settings per segment of a winding profile, such as setting a variable laser intensity along the profile to accommodate varying winding speeds. Source | TANIQ

That project has also compared thermoplastic LATW tanks with Type 4 thermoset composite pressure vessels made with wet winding. Currently, TPC tanks are much more expensive to manufacture, due to the higher cost of the TPC tapes, investment in the LATW application head, and the slower production speed versus wet winding or thermoset winding. However, Blomaard notes an important benefit is the possible recyclability of the carbon tape by melting the plastic. Fraunhofer IPT has developed technology for regaining continuous fiber back from these TPC tanks at the end of life. “This changes the value because you are not shredding the vessel and reusing chopped fiber composites but actually reversing the process,” he explains. “I think eventually we will see thermoplastic composite tanks in the future due to this type of recyclability.”

While TANIQ has compared different winding systems, notes Blomaard, “we also believe in the development of hybrid systems. These can involve the use of different materials (e.g. glass fiber and carbon fiber) into a single tank, or a combined process of winding and placement.” TANIQ is currently involved with several research institutes and companies such as Cevotec (Unterhaching, Germany) that are applying a local dome reinforcement in combination with winding of towpreg or TPC tapes. “We are developing the functionality to design these local paths and patterns, and to calculate the local thickness build-up, and export this data to the FEA software,” says Blomaard. “By merging these functionalities the TaniqWind Pro software extends from winding software to placement software, and robotic winding systems and tape winding systems merge into hybrid production cells.”

Winding technology development

Blomaard points out that a significant amount of technology has already been developed in tank design and production. “In the past, I had the feeling that universities were ahead of industry, but with composite pressure vessels, the industry seems to be far ahead of the universities,” he says. “We have seen this during collaboration in various projects and we hired people who used to work at some of these tank companies. There is a high level of detail in pressure vessel design, testing and testing setups — and so much knowledge already developed within certain companies. They are so far ahead, and yet nothing is published. It was surprising to learn that so many different companies individually are working on the same solution. It seems there is very little being shared.”

These companies have typically had a fairly narrow focus in the types of tanks they are building, says Blomaard, and have spent years performing trial and error to optimize these designs for serial production. But as the whole industry migrates to more digital production, these companies are also measuring and trying to make sure that what they are modeling is actually what they're building. “This activity is labor intensive and time consuming,” says Blomaard. “What we are aiming to do is make a software that if you want to make a new design from scratch, then these predictions will already be good or at least much more reliable than they have been before. And we think from the winding software perspective, if you can integrate that knowledge and those models, then it will be much more efficient for companies that don't have the time or the capacity to do this kind of iteration for optimization. Our goal is to help enable new composite tank designs, which will be needed for future vehicles.”

Related Content

Optimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

Read MoreOptimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

Read MoreThe basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)