Large U.S. capacity, solid base for growth

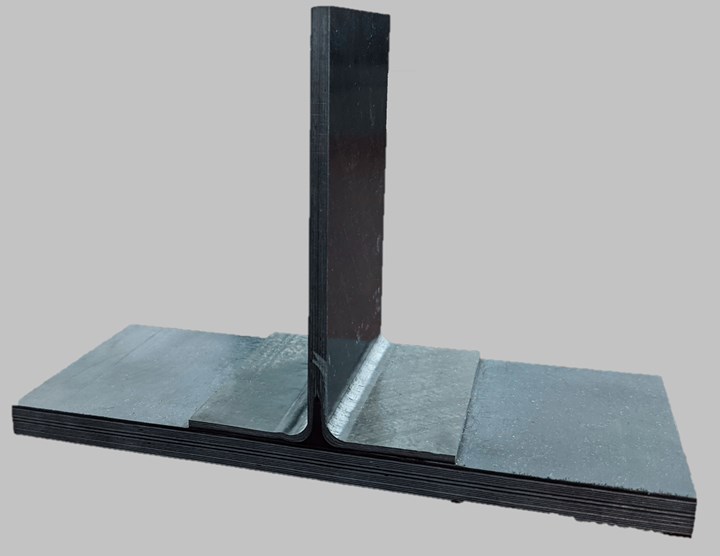

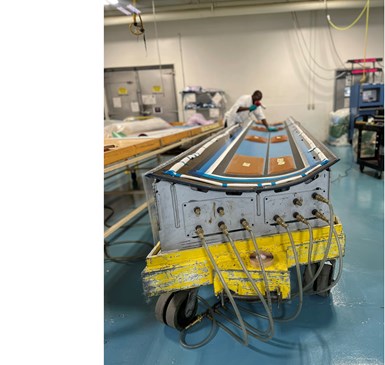

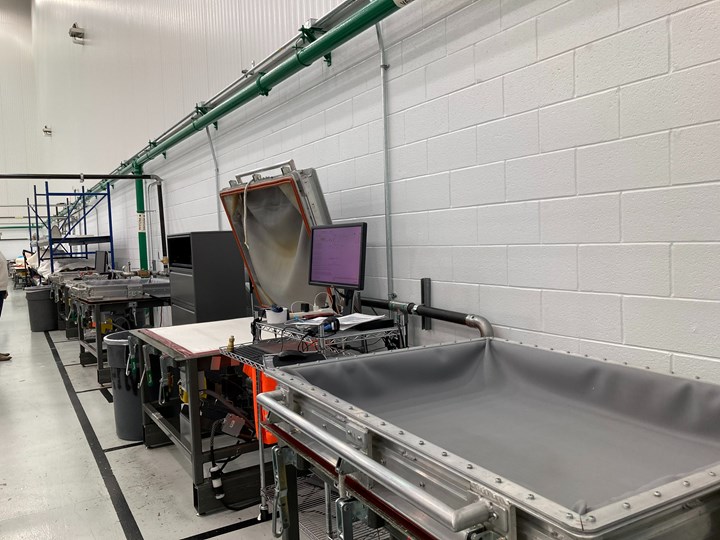

Qarbon Aerospace produces a wide range of composite aerostructures at its Red Oak (top) and Milledgeville (bottom) sites. Photo Credit, all images: Qarbon Aerospace

Qarbon Aerospace (Red Oak, Texas, U.S.) is a Tier 1 supplier of composite and metallic aerostructures with 1.6 million square feet of manufacturing space spread across three facilities: 772,000 square feet in its headquarters, 650,000 square feet in Milledgeville, Georgia, and 150,000 square feet in Rayong, Thailand. It is a phoenix, emerging on May 1, 2021, as a stronger private entity, acquired from Triumph Group’s (Berwyn, Pa., U.S.) aerospace structures division by the equity firm Arlington Capital Partners (ACP, Chevy Chase, Md., U.S.).

Much of the company’s leadership and workforce has been retained, which is a strength, says Qarbon CEO Pete Wick, previously executive VP of aerospace structures for Triumph. “You won’t find a better workforce with a better work ethic and determination to succeed. Our workers and leadership have decades of experience and are in this for the long haul.” He explains that, in size, Qarbon Aerospace sits in between the few very large Tier 1 aerostructures suppliers, like Spirit AeroSystems (Wichita, Kan., U.S.) and GKN Aerospace (Redditch, U.K.), and myriad smaller suppliers, where margins have been traditionally low, resulting in a lack of ongoing investment. “Under previous ownership, we faced that same struggle, but now we finally have the backing to reinvent this business and take it forward to where it deserves to be.”

The company’s vision statement is “Aerostructures Reimagined.” That concept, Wick explains, “is for us to have not only the reputation of being completely dependable, but also very agile. Our commitment is quality products, on time and competitively priced, but also a quick response and readiness to meet the needs of future programs.” This is reflected in the company’s name, says Evan Young, Qarbon’s head of engineering. “Carbon with a ‘Q’ comes from our mission, focused on quality and doing things a little differently.” The latter ranges from the company’s patent-pending induction welding technology for thermoplastic composites (TPC), to its patented TPC-based Helios deicing/icing protection system, to its latest contracts in the advanced air mobility (AAM) and New Space markets.

A tour of two facilities

Qarbon’s Milledgeville and Red Oak facilities are vast; the tours take hours. Red Oak processes ≈350,000 pounds of thermoset composites material to produce ≈23,000 components per year. Milledgeville feeds parts into Red Oak, so its part count is even higher. Red Oak is the largest and newest site, built in 2013, but its history reaches back to renowned aircraft OEM Vought, known for the F-8 Crusader, A-7 Corsair, the wings for the B-2 Stealth Bomber and Gulfstream G550 business jet, the V-22 Osprey empennage and more. Its Marshall Street facility in Grand Prairie, Texas, and nearby Jefferson Street facility in Dallas totaled 6 million square feet. After acquiring Vought Aircraft Industries in 2010, Triumph consolidated much of the Jefferson Street work into Red Oak, which is located just south of Dallas and designed for very large integrated structures. It also produces metallic structures, while Milledgeville and Rayong are 100% composites.

The Milledgeville plant was built in 1975 by Northrop Grumman (Falls Church, Va., U.S.) to build the F-14, F-111 and A-6 fighter/bomber jets and the E-2C and EA-6B electronic warfare planes for the U.S. Navy’s carrier strike force. Current production includes parts for the Boeing (Chicago, Ill., U.S.) 787, Gulfstream (Savannah, Ga., U.S.) G650 business jet and the elevators and rudder for Embraer’s (São Paulo, Brazil) E2 E190, E195 and E175 jets. Milledgeville has also built CF-6 transcowls for the Boeing 767, commercial and military, since 1983 as well as flaps, ailerons and spoilers for the Boeing 777 wings since 1992. Both facilities have made parts for the V-22 Osprey tiltrotor since 1998. “In general, Milledgeville produces medium to large composite structures,” says Young, “while Red Oak produces large to extremely large assemblies, such as the 131-foot wing for Northrop Grumman’s Global Hawk and Triton HALE [high-altitude, long-endurance] unmanned aircraft.” Milledgeville supplies roughly 400 part numbers to Red Oak for that wing.

Qarbon Aerospace’s large parts capabilities at Red Oak includes this new Fives 80-foot five-axis trim and drill cell.

This difference in assembly size can be seen in how the two sites are arranged. The majority of Milledgeville’s ≈126,000 square feet of layup and bonding operations is separated into six bond shops, while Red Oak has two, the largest covering 65,000 square feet. There are three main assembly halls in Milledgeville, while two-thirds of the Red Oak building is dedicated to assembly, with four separate bays stretching 600 feet, sized to accommodate, for example, full systems integration for the HALE wing. “When the wing leaves our plant,” notes Young, “it’s got all the flight controls, landing gear, electrical, hydraulics and icing protection systems installed and it’s been structurally tested. That’s a unique capability. Both sites give Qarbon a broad scale, from detailed parts fabrication and benchtop assembly to large, fully integrated structural modules delivered to OEM final assembly lines.”

Red Oak is also the company’s high-temperature composites center of excellence, producing the high-pressure compressor duct for the F135 engine. “We have experience with polyimide, BMI [bismaleimide] and pre-ceramic materials,” says Young. All four of the autoclaves at Red Oak are high-temp capable and three are 60 feet long x 15 feet in diameter. Milledgeville’s six autoclaves range from 65 feet long x 12 feet in diameter to 8 x 20 feet. Both facilities have multiple sets of 45- and 60-foot-long Gerber (Tolland, Conn., U.S.) rapid ply cutters, large CNC trim and drill centers, Fives (Hebron, Ky., U.S.) automated tape/fiber placement (ATL/AFP) machines and automated non-destructive inspection (NDI) cells. Both sites have upgraded these capabilities over the past year as well as revamped the company’s digital infrastructure, replacing legacy systems with a single suite optimized to manage composite materials and manufacturing.

Thermoplastic composites

Welded thermoplastic composites

Qarbon Aerospace’s patented robotic induction welding technology for UD composites (top) has been advanced to TRL 5 for closed-box aerostructures, such as the wing box demonstrator displayed at CAMX 2021 (center) and this flight control demonstrator (bottom).

Qarbon has also invested in the development of TPC technologies. “Our patent-pending process for induction welding UD [unidirectional] carbon fiber thermoplastic composites,” says Young, “allows us to weld dissimilar thicknesses, curved structures and with access to only one side.”

John Monsees, Qarbon’s chief technologist for thermoplastics, explains that the technology is unique in how it isolates the heat created by the induced electromagnetic field within UD carbon fiber-reinforced plastic (CFRP) laminates. “We can very precisely control the energy at the weldline interface, which allows us to weld parts without tooling, for example, and we are getting higher strength properties than those published by other companies.” Young recounts results on welded poletheretherketone (PEEK) and polyaryletherketone (PAEK) laminates that Qarbon presented at CAMX 2021: “Our induction-welded joints showed a single lap-shear strength of 6.5-6.75 ksi, which is 30-40% higher than the industry standard co-cured joints with mechanical fasteners.”

“We also have unique ways for designing induction welding heads,” adds Monsees, “and are scaling the six-axis robotic end effector we have built to provide efficient process control. Because we require access to only one side, we can rapidly weld small flight controls.” Young says Qarbon is pursuing this type of low-risk, low-volume part as a first production program and has already demonstrated that capability to technology readiness level (TRL) 5. He notes that Qarbon is welding at 0.5 inch/second, or roughly 10 times the speed of standard aerospace automated riveting.

Qarbon sees this technology as an enabler for the next generation of aerospace vehicles. “It allows us to move away from large, dedicated tooling to a modular assembly cell using a gantry-based robot,” says Young. “That lets us assemble multiple different types of structures quickly.” In a study completed with the Air Force Research Lab (AFRL, Dayton, Ohio, U.S.), Qarbon compared thermoset to thermoplastic composites for the same airframe design but at UAM production rates. To build 10 shipsets/day for 2,500 shipsets/year requires additional freezers and autoclaves for thermosets as well as nine sets of tools, says Young, while thermoplastic parts are molded in minutes. “The result is a 39% reduction in manufacturing footprint, 87% reduction in tooling and 64% reduction in labor due to more automation,” he adds. An internal study also showed that programs with >60 shipsets/year should look at TPCs. “This is the discussion we’re having with all of our customers,” says Young.

Qarbon’s patented Helios icing protection system is also TPC-based. “It uses a very thin heater element that goes onto the wing structure,” explains Young, “so it is not just for new aircraft designs but also for retrofit. You simply take off the legacy systems, such as pneumatic rubber boots, and put our thin structure back on, which saves weight and maintenance costs.” This technology also enables very power-efficient electrification of aircraft. The aim, says Young, “is to deliver a turnkey system: heating structure, wiring harnesses, power distribution elements and cockpit controller, all kitted in a box labeled Qarbon Aerospace.”

Milledgeville bond rooms

The Milledgeville tour begins in Bond Room 1, where CF-6 transcowls, Boeing 777 spoilers and G650 winglets, spoilers and trailing edges are laid up. Laser projectors from Virtek (Waterloo, Ontario, Canada) and Aligned Vision (Chelmsford, Mass., U.S.) are mounted overhead throughout all of the bond rooms.

Milledgeville Bond Room 2

CF-6 transcowl layups have been transferred onto male tools from female tools seen in the background (top). A wing flap layup (bottom) features multiple machined honeycomb core pockets.

Here, the CF-6 transcowl layup stations use two laser projectors, one on each side of the tooling — necessary because of the part’s curvature. “These parts are laid up on female tools and then transferred to male tools for autoclave cure,” says Milledgeville value stream manager Wesley Spires, noting a build rate of four/month. For G650 trailing edges, he continues, “we lay up and cure the CFRP bottom and top skins and then co-bond these in a second autoclave cycle.” This type of assembly, with multiple bonding and autoclave steps, is common throughout the Milledgeville and Red Oak plants. Spires next points out detail parts being laid up for the HALE wing assembled in Red Oak, including leading edges, trailing edges, ailerons, spars and two spoilers with internal ribs and baffles.

Bond Room 2 houses layup for the flaps (one outboard, one inboard), spoilers (five outboard, two inboard) and outboard aileron for each 777 wing. Spires notes the largest of these is 32 feet long. Across the aisle, glass fiber prepreg parts are laid up for these assemblies, including ribs. A black caul plate lies next to a layup for one of the large 777 flaps. “We make our own caul plates,” says Spires. Many are made using a non-silicone rubber material called Airpad from Airtech International (Huntington Beach, Calif., U.S.). In the back corner of this room, a technician creates bags from rolls of vacuum film and kits these with the consumables needed for each part. These are scheduled daily and delivered to each station.

Bond Rooms 4 and 5 house production for the Embraer E2. This program, started in 2013, comprises three sets of elevators, but the same rudder for all three models. “The rudder uses multiple spars,” says Spires. “We lay up the first skin and then the spars on three different mandrels.” Each spar layup is picked up with an overhead crane and placed onto the skin layup. Pins on the mandrels align with holes in the skin tool. Noodles at the spar-skin interface — a standard practice in composite skin-stringer assemblies — are made in-house from UD prepreg. Next to Bond Room 4 is the reticulated adhesive room. Here, a specially formulated adhesive is sprayed onto the cored sections of the CF-6 transcowls in a vented spray booth.

Bond Room 6 robotic layup cell

This Comau robot cell automates layup and debulking of prepreg plies for Boeing 787 parts but has capacity for space vehicle parts.

Bond Room 6 houses a Comau (Grugliasco, Italy) robotic cell used to produce 787 fuselage barrel shear ties. Before COVID-19, says Spires, the 787 production rate was at 14/month, and two stations were required to lay up and debulk plies onto mandrels by hand. “The robot cell could speed up layup to meet our rate requirements with only three technicians, a 25% savings in labor,” he says. A spider-like part with six tube-like appendages is currently in the robot cell. A secondary structure for a space vehicle, it’s in the final stages of manufacturing optimization. “We have capacity in this cell that could be used for future space vehicle work,” adds Spires.

Milledgeville AFP, autoclaves, NDI, assembly

Two Fives AFP cells build layups for the V-22 Osprey tiltrotor sponsons (which form the bottom of the engine pods) and main landing gear doors. “This area is also where we lay up the 45-foot spars for the HALE wing,” says Spires. A 7.5-foot-tall, 13-foot-diameter mock-up fixture sits in one corner. It represents the large layup tool for a space launch vehicle structure that will be built here soon. “We’ll use this room’s high-capacity crane to rotate and manipulate the layup tools,” says Spires.

In the staging area outside the 45-foot-long, 15-foot-diameter autoclave #6 (Thermal Equipment Corp., Rancho Dominguez, Calif., U.S.), a variety of female tools with layups for the V-22 sponsons await cure. The V-22 loading ramp/door is also prepared for cure in this room. Nearby is the staging room for the 65-foot-long, 12-foot-diameter autoclave #7 supplied by ASC Process Systems (Valencia, Calif., U.S.). An adjacent CNC trim room is filled with vacuum trim tools and an 11.8-foot-wide x 30-foot-long Belotti (Suisio, Italy) CNC machining cell. Seven such CNC machining cells from various suppliers are spread across Qarbon’s three production sites. “All of the 777 flaps and E2 parts are trimmed here,” says Spires, pointing to an E2 trailing edge part that is being milled for weight reduction.

The main autoclave area, which houses four autoclaves — ranging from 8-12 feet in diameter and 20-50 feet long — is used primarily for curing 777 parts, says Spires. On our way out, we speak with Gwen Foster, lead technician for the G650 spoiler, who has just celebrated her 46th year working here and remarks how much she still enjoys her work.

Milledgeville NDI and assembly

One of the sites's three automated UT inspection cells, featuring dual Kuka robots for TTU scanning (top), and one of five fixtures used to assemble Embraer E2 rudders and elevators (bottom).

The first of three large NDI areas in Milledgeville houses two General Electric (Boston, Mass., U.S.) ultrasonic testing (UT) units — one robot-based and one gantry-based — and one Panametrics Inc. (Waltham, Mass., U.S.) gantry-based TTU (through transmission) UT machine. All are equipped with water squirters and used to inspect engine transcowls, 777 flaps and parts for the V-22, G650 and Northrop Grumman aircraft programs. Another NDI area nearby contains a Marietta NDT (Marietta, Ga., U.S.) DDA X-ray room and two large C-scan tanks — one is a pulse-echo phased array UT system, used to inspect Embraer control surfaces, while the other is a reflector plate inspection system (providing reduced signal noise scans for dense composites parts) used on 777, Embraer, V-22 and G650 composite parts. “It takes two shifts to C-scan a large part using these machines,” says Spires. He notes that a new Automated Ultrasonic Scanning System (AUSS) supplied by Boeing and scheduled for installation in October 2022 will complete the same scan in four hours using phased array UT.

In the first of two large assembly areas, a G650 fixed inboard trailing edge is being assembled, including three bonded composite parts to which various components and systems are being mechanically fastened. The G650 winglet stations are next. Further on is a fixture for assembling detail parts for the HALE wing, followed by areas for assembling 777 spoilers and 767 seal beams and depressor panels. One spoiler is receiving hinges and fittings, attached with mechanical fasteners. These will then get a “cap seal,” says Spires. “Two technicians hand paint this rubberized polymer sealant on top of every fastener and do an expert job in meeting the precise requirements.” Next, a CF-6 transcowl being assembled comprises three bonded composite parts — inner skin, outer skin and C-channel. Six customer-provided hinged blocker doors are installed along the lower circumference of the semicircular transcowl.

In the final NDI area, 787 shear ties are being inspected in smaller UT tank systems. There are also several more CNC cells, including a Belotti MDL 5036 trim cell and two machining heads on a single rail from Diversified Machine Systems (DMS, Colorado Springs, Colo., U.S.). Across from the DMS cell, there is a Global DEA coordinate measuring machine (CMM) and a Leica laser tracker for geometric scanning, both supplied by Hexagon Manufacturing Intelligence (Cobham, U.K.). There is also a newly installed CUBE-R automated 3D Scanning CMM cell by AMETEK (Berwyn, Pa., U.S.) in partnership with Creaform (Lévis, Quebec, Canada). The closed 4.1- x 4.1- x 3.1-meter cell uses a robot-mounted optical 3D scanner that can reportedly measure hundreds of parts per day with an accuracy of 0.08 millimeter.

Just beyond the final NDI/trim room is a paint room with three prep booths, three spray booths and two drying ovens. “Only the E2, G650 and 777 spoiler parts receive their final paint coats here,” says Spires. “All other parts receive just primer coats.” Next to the paint room, a large shipping area occupies this end of the building, filled with finished 777 ailerons, 787 shear ties and 777 straps and clips. Across from this is the second assembly area where five large fixtures from Odyssey Industries (Lake Orion, Mich., U.S.), a division of Ascent Aerospace (Macomb, Mich., U.S.), are used to assemble the Embraer E2 rudder and elevators. The right- and left-hand elevators seen here, notes Spires, comprise the integrated stringer-stiffened skins and ribs and are produced at a rate of four/month.

Red Oak layup, bond and post-bond

“Thermoset composite layup and post-bond operations comprise one-third of the production space here,” says Dale Cooper, general manager for the Red Oak facility. The rest is characterized by an expansive 42-foot- high bay production space for large major assembly and integration operations. Walking through Red Oak’s largest, 65,000-square-foot bond shop, we see moderately sized V-22 Osprey tiltrotor parts, made using tabletop hand layup operations and heated compaction tables. This expands to additional production zones for very large and complex contoured structural parts for Bell Flight’s (Fort Worth, Texas, U.S.) 525 Relentless fuselage and the 55-foot-long wing skins and spars for the Triton HALE aircraft. As in Milledgeville, laser projection systems are used throughout the various layup stations.

The tour pauses at a production area for the F135 engine high-pressure compressor duct. “This product progresses through several layup and low-temperature debulk cycles before a final high-temperature cure,” explains principal manufacturing engineer, Fred Adair. His vast experience in composites began in 1982, when he joined the company via a Vought subsidiary. “In part, the factory was built with this type of high-temperature capability in mind, and all the autoclaves and primary ovens here are designed to support this type of production.

Gulfstream G600 HTP production

The G600 horizontal tail plane (HTP) comprises CFRP stringers made using an Accudyne automated stringer former (top) which are placed onto ATL skins (bottom) and co-cured in an autoclave.

The tour next enters the second bond room, which includes operations for the Gulfstream G600 horizontal stabilizer (or tailplane, HTP) and HALE wings. Although layup and bond operations at Red Oak are done predominantly via hand layup, this room is commanded by a Fives five-axis ATL machine and an Accudyne Systems Inc. (Newark, Del., U.S.) automated stringer-forming machine. These are used to produce the G600 HTP, comprising 40-foot skins and precision net-trimmed stringers that are assembled here and co-cured in an autoclave.

Exiting the second bond room, post-bond operations span multiple zones that house an array of CNC trim and drill cells, as well as automated UT and X-ray NDI equipment. “We recently invested to expand our large-parts capability,” says Cooper, “by adding a Fives 80-foot, five-axis trim and drill cell and a Genesis [Davenport, Iowa, U.S.] 60-foot robotic UT system which supports through-transmission and phased array inspection.”

Red Oak productivity and certification

The rest of the Red Oak factory showcases the major structural assembly, systems integration and functional testing that Qarbon Aerospace offers. Supporting these assembly programs, metallic parts are sourced from a global supply chain, while composite details are vertically integrated from Red Oak’s layup/bond shops as well as Qarbon’s other sites in Rayong and Milledgeville.

Red Oak productivity

Heated compaction tables quickly debulk prepreg layups (top) and this Genesis robotic NDI cell can scan large structures in as little as 30 minutes (bottom).

The largest composite assembly programs at Red Oak include the Triton HALE wing and V-22 empennage. The Triton 131-foot wing assembly takes up one entire assembly hall. A dominating feature here is a 145-foot-long test fixture used to stretch every Triton wing in a positive and negative deflection before it is sent back through UT inspection to validate the integrity of the adhesive bonds between skin and structural grid. This illustrates Red Oak’s capability for structural test engineering, says Cooper. “We install strain gauges, perform this type of testing and also install flight test strain gauges during assembly as an added value to our customers. This is required, for example, with new product introductions or major configuration upgrades.”

Qarbon is completing such an installation on several large structures for the Boeing T-7A Red Hawk trainer jet. This program’s metallic structures production, currently in the engineering and manufacturing development (EMD) phase, is the next assembly area, just beyond the HALE assembly bay. “We’re installing all the strain gauges and instrumentation wiring for fatigue, static and flight test articles,” notes Cooper.

Next is the Red Oak facility’s 50,000-square-foot Agile Manufacturing Center, which houses R&D and testing support, for example, a large test fixture used for performing aircraft carrier drop test qualification. “This is a complex test to simulate aircraft landings on carrier ships,” says Young. “We completed this testing for F-35 and CH-53K structures.” An equally tall 300,000-pound tension test rig is used for engineering verification. “The only other non-OEM test rig this large,” notes Young, “is at NIAR [Wichita, Kan., U.S.], used for large commercial aircraft testing.” He then points to an Embraer E195-E2 elevator that is an actual test article for certification: “We will complete static and fatigue testing for this part which is 90% composites.”

In the back corner is a full test lab with 15 Materials Test Systems (MTS, Eden Prairie, Minn., U.S.) machines and environmental chambers. “We can test all the way from simple coupons to full-scale, integrated structures,” notes Young. An adjacent 6,000-square-foot R&D layup room contains a dedicated high-temperature oven, autoclave and press. “We can support programs from concept to prototype to LRIP [low-rate initial production] and then full production,” notes Young. “The first structures for the HEXA eVTOL [see below] were prototyped here and then transitioned to our plant in Thailand,” he adds.

Capacity for UAM

The tour stops briefly in the thermoplastic composites lab (see TPC discussion above) before entering another of the four assembly bays at Red Oak, parallel to the HALE assembly bay and just as long. It is mostly unoccupied, and Cooper notes that Red Oak has roughly 60% open capacity, “but as the economy grows post-COVID, we are seeing more opportunities and expect to begin filling this out. Red Oak is a key part of our entry into new markets, such as UAM [urban air mobility].”

In the middle of this bay sits a completed ultralight HEXA electric vertical takeoff and landing (eVTOL) aircraft for LIFT Aircraft (Austin, Texas, U.S.). “We are building the CFRP body, passenger cell and rotor frame, all from thermoset prepreg, as well as the six-piece spider-like landing gear in our Thailand plant,” he says. “Those parts are then sent here and assembled into a completed unit, ready to be delivered. Production started in 2021 for initial manufacturing development and the team is rapidly moving toward low-rate initial production.”

In the U.S., HEXA is approved for flight under FAR Part 103, the Powered Ultralight classification, for which FAA certification is not required or available. However, it must weigh <254 pounds empty, carry only one person and not exceed 55 knots in level flight. “You don't have to be a licensed pilot to fly it,” says Cooper. LIFT Aircraft’s current business model is to open 25 airparks in the U.S. for public flights. “LIFT is planning to start a traveling tour with a couple of vehicles,” he says, “and they already have about 15,000 people that paid for tickets to fly the aircraft.” The first HEXA vertiport is slated to open later in 2022. The balance of HEXA’s manufacturing volume is targeted for military applications and a cargo variant. LIFT Aircraft was awarded SBIR Phase I and II grants by the U.S. Air Force AFWERX Agility Prime program aimed at incorporating eVTOL aircraft. The cargo variant is being discussed for a range of commercial applications.

Growing even larger

Wick says that Qarbon is well positioned, both in its capabilities and investments. “We know our strategic fit and we can build upon this to fill these facilities, while continuing to develop technology for the longer term. We are excited about the UAM and New Space markets, and about the relationships we’re building in both. The large structures for space and complete UAM airframes are a good fit for us, and we can help accelerate OEM production as demand increases in both markets. I also think this decade will see a thermoplastic composites revolution. The UAM market will begin fueling significantly more interest in the kind of technologies we've developed, including Helios. But thermoplastic welding is also going to enable the next generation of single-aisle commercial aircraft. Before COVID-19, Boeing and Airbus were discussing next-gen production rates approaching 100 per month, which isn’t feasible with a thermoset composites baseline.”

Wick says ACP has challenged the leadership team to grow both organically and through acquisitions. “We have a half-dozen strategic targets,” he adds, “but we’re not going to buy anything just to get bigger. We are looking at technologies that will be complimentary but also give us an edge, and we intend to expand our reach in Europe.” His first priority, however, is to continue filling capacity at Red Oak, Milledgeville and Rayong. “I want to grow our military and commercial portfolio, and I’m excited about the potential for securing more work in engine ducts and cowls. In a very short time, Qarbon Aerospace has managed to get its name known. We have major opportunities at our fingertips. This is the smallest that Qarbon Aerospace will ever be.”

Related Content

CompositesWorld's top ten plant tours of all time

The editors at CW have been lucky enough to visit many unique facilities over the years. These tours have provided an in-depth look into these company’s manufacturing processes and their of state-of-the-art equipment and technologies. Here are the top ten plant tours our audience took an interest in.

Read MorePlant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

Read MorePlant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

Read MorePlant tour: Renegade Materials Corp., Miamisburg, Ohio, U.S.

Renegade Materials is known for high-performance prepregs for aerospace applications. Following its acquisition by Teijin in 2019, the company has expanded capacity and R&D efforts on a range of aerospace-targeted materials.

Read MoreRead Next

Qarbon Aerospace at CAMX 2021

Learn more about Qarbon Aerospace’s worldwide footprint, expertise in thermoplastics, and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More