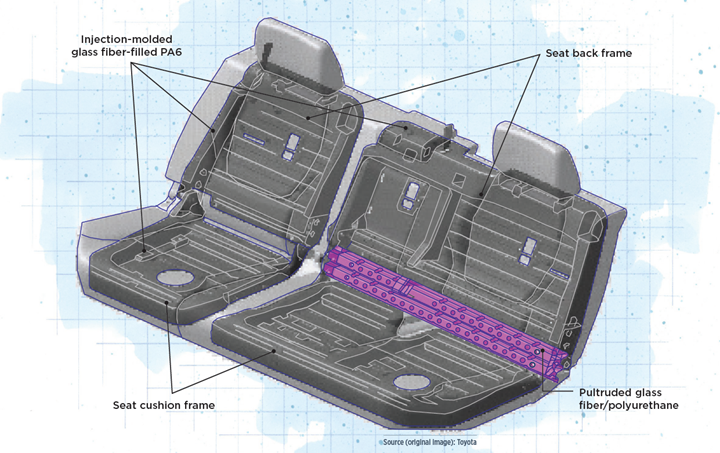

“Next-generation truck” design. When designing the 2022 Tundra pickup truck, Toyota’s engineering team in Ann Arbor, Mich., U.S., looked for ways to make the vehicle — which comes in conventional powertrain and hybrid options — as lightweight and efficient to manufacture as possible. One resulting innovation is a composite second-row seat frame that saves significant weight versus a steel version and reduces the overall number of frame components from 60+ to just four. Photo Credit: Toyota

As more electric and hybrid electric vehicles launch into the market and hit the road, automotive OEMs are increasingly exploring composites use to reduce weight for various components to help increase vehicle range. One recent success is the award-winning, all-composite, second-row seat frame for the hybrid-electric 2022 Toyota Tundra pickup truck — a collaborative, multiyear endeavor introducing a number of new composite materials and process innovations.

John Salvia, senior engineering manager at Toyota Motor North America, Research and Development (Ann Arbor, Mich., U.S.), explains that in 2018, Toyota engineers at his Ann Arbor facility began to brainstorm “the next-generation truck.” “We started out looking at what would be the most efficient design moving forward,” he says, and specifically tried to envision how to make the design for vehicles with second- or third-row seating more efficient and cost-effective to manufacture. A range of materials were evaluated, including aluminum, carbon steel and various fiber-reinforced composites.

The customer experience was also a key consideration. When it came to developing the 2022 Tundra, Salvia notes, customer feedback from the previous model year vehicle communicated a desire for more dedicated storage space within the cabin. However, this desire also had to be balanced with the fact that in the Tundra’s new hybrid option, the battery pack would be stored underneath the rear seat.

With the broad initial goals of cost-effective, efficient manufacturing, light weight and design flexibility to enable more storage space, fiber-reinforced composites emerged as the top material contender.

“Of course, we already had one proven composites example in our back pocket,” Salvia says. The third-row seat frame for the 2021 Toyota Sienna minivan was manufactured from injection molded 35% short glass fiber-filled polyamide 6 (PA6) developed in collaboration with BASF Corp. (Wyandotte, Mich., U.S.). The Sienna seat frame went on to win a 2020 Altair Enlighten Award in the Module category as well as a 2021 SPE Innovation Award in the Body Interior category. The Sienna seat frame was lauded for replacing the previous models’ 16-piece steel assembly with a two-piece composite part that was 30% lighter. BASF’s glass fiber-filled Ultramid B3ZG7 CR PA6 was developed specifically for the project (more on this below).

According to Jeffrey Hagar, market segment manager – transportation at BASF, composites were chosen for the Sienna seat frame primarily for lightweighting. The steel-framed third-row seat was too heavy for customers to easily fold up or remove if needed. One solution, Hagar says, would have been to install a mechanical motor to fold the third-row seat up and down, but that would’ve added weight. The lighter composite version was developed as a solution.

After this success, Hagar says the Toyota team approached BASF again with a new project idea, “this time with even bigger goals and objectives.”

Specifically, Toyota aimed to develop a new seat frame design that, compared to the previous steel-framed Tundra second-row seatbacks, reduced weight by 20%, improved manufacturability, added dedicated storage space for the customer and doubled overall structural strength.

The biggest challenge compared to the Sienna? The Tundra pickup truck is simply bigger than the minivan: The second-row seat frame would need to be 30% wider than the Sienna third-row seat.

Materials, design: Starting from Sienna

“A seating system is a fairly complex system to design, so the challenge of a seating systems engineer is to balance many different challenges and targets,” Salvia explains.

Passenger-focused design. Critical among the design considerations were passenger safety standards, as well as a desire to increase dedicated storage space in the vehicle cabin. These led to innovations in the second-row seat frame such as the use of a specialized, crash-resistant, glass fiber-reinforced PA6 material from BASF for the main frame components, and the addition of a pultruded beam to increase strength and stiffness in key areas of the seat. Photo Credit: Toyota

The Tundra is a 60/40 seat design, common for vehicle rear seating, meaning the seat is divided into two main sections — one that takes up 60% of the space, the other 40%.

Salvia says, “When you look at how we would design a steel seat structure, first you start with the structural beams — your core components — and then you add on features for shape or electronics or whatever you need by welding them onto that steel structural beam. You kind of piecemeal the design together, which is efficient from a design standpoint, but when you get to manufacturing you end up with many small structural welds and a lot of part handling and quality checks.”

The design process started with hand-drawn sketches, ultimately digitized and validated virtually with digital simulation tools. Because materials played such a vital role, Salvia explains that BASF’s role was similarly large in the design process. Hagar notes, “Toyota developed the design and styling, and BASF optimized the design for the materials and provided engineering best practices.”

In working on the Sienna, BASF used its in-house UltraSim software to model several of its off-the-shelf materials against the crash requirements and quickly realized that a new grade of material would be needed. “We started with our base Ultramid and we were able to make some modifications to the resin and to the orientation of the glass fiber, and to how they attach to each other,” Hagar says. The new Ultramid grade material is labeled Crash Resistant, or CR.

For the Tundra, BASF started by running new simulations with this same Ultramid B3ZG7 CR 35% glass fiber-reinforced PA6 material. “We had about a year’s worth of field information from the Sienna and knew we had zero field failures on the market, so we were confident this was the right grade of material for the Tundra as well.”

For ease of manufacture, the seat frame components would be injection molded from this new material. The choice to use injection molded composites, like in the Sienna, allowed for more than 60 individual metal components to be optimized into only four composite components — two seat back frames and two seat cushion frames — attached via metal brackets, plus the cushions and additional components for the built-in storage option.

Salvia notes that the design flexibility of the composite seat frame also enabled the opportunity to efficiently add new storage bin options to the 2022 Tundra. On the hybrid powertrain option for the vehicle, the battery is housed under the second-row cushion and a dedicated polypropylene storage bin is attached to the back vehicle wall. On the conventional powertrain option, a second storage bin is offered under the seat in place of the battery.

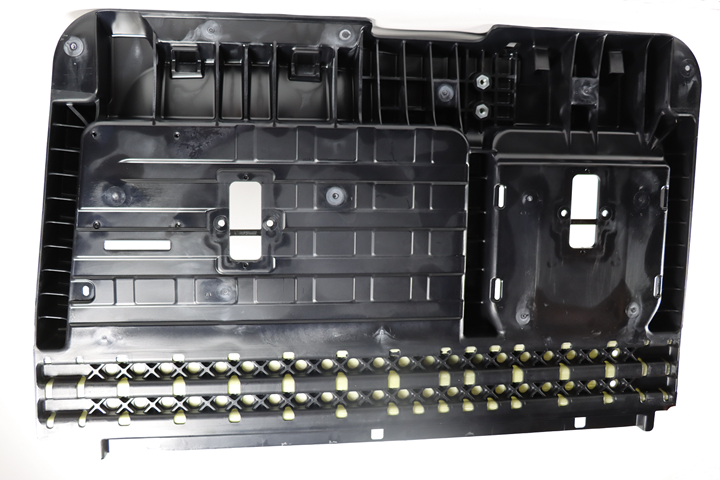

Ready for assembly. A pultruded beam (yellow/green in picture) is attached via injection overmolding onto the largest of the four injection molded frame components. The final pieces are then assembled together with the rest of the frame system. Photo Credit: BASF

The main composite components were manufactured by injection molder Flex-N-Gate (Warren, Mich., U.S.). According to Steve Perucca, engineering group manager – R&D plastics/metals at Flex-N-Gate, the company has worked with Toyota a number of times on injection molded pickup truck bumpers and other components.

In addition to molding the components, Perucca notes that a number of small metal inserts were injection overmolded into the frame components where other seat components needed to be attached. Salvia explains, “We tried to consider everything together as a system, where the structural beams are seamlessly integrated with other features.” All of the seat features, cushion frames, back frames, headrest attachments, electrical attachments and brackets are incorporated into the design from the start. “There are fewer components, less material handling, less margin for quality defects. We’ve streamlined the manufacturing process and improved the quality overall.”

From a materials standpoint, the BASF glass fiber-reinforced nylon used on the Sienna showed the best balance between cost, mass and performance for the Tundra as well. However, early in the design process it became apparent that the extra width for the Tundra seat frame would pose a new challenge to meeting Toyota’s strict safety requirements. To achieve the needed stiffness, the overall frame would either need to be very thick — which would add material costs and weight — or some type of reinforcement beam would need to be added to the area carrying the heaviest loads. A beam of this type made the most sense, but would typically be metal in this sort of application — adding additional weight. A pultruded composite beam ended up being the ultimate solution.

Developing the pultruded beam reinforcement

“Our supplier BASF approached us with this continuous glass fiber pultrusion technology, which has a higher strength-to-weight ratio than high-carbon steel,” Salvia says.

Pultruded beam: Stiffness and strength with less weight. To achieve the needed strength and stiffness along the seat back frame’s width, the seat back frame would either need to be much thicker (adding weight) or a strategically placed beam needed to be added. A pultruded composite beam was chosen for its high strength at a lighter weight compared to metal options. Photo Credit: Toyota

BASF introduced the Toyota team to its pultrusion partner L&L Products (Romeo, Mich., U.S.). BASF and L&L Products had worked together on multiple projects, using BASF’s Elastocoat 74850 polyurethane/fiberglass material to produce L&L Products’ pultruded Continuous Composites Systems (CCS) products. Previous applications have included structural automotive components where crash resistance was of critical concern — like, most recently, a cross-member used to protect the battery system on the all-electric 2022 Ford F-150 Lightning. BASF was confident that this product could be an ideal solution for the Tundra seat frame; however, this solution had never been used for any type of interior automotive application before.

Like the rest of the seat frame, modeling and simulation played a key role in the design process for the beam itself, to make sure it could adequately meet the load requirements for safety, passenger weight and other targets. Several design iterations were tested in simulation and as physical prototypes.

What makes the pultruded beam crash-resistant? A combination of resin chemistry tuned for very high stiffness, continuous glass fibers for maximum flexural strength and optimized part geometry, explains Hank Richardson, product engineering manager at L&L Products.

Why pultrusion? He adds, “Pultrusion was the most cost-effective process to use. You get very high flexural strength because of the continuous fibers, but it’s lighter weight than aluminum or steel, so the strength-to-weight ratio is very high. And the pultrusion process itself is fairly simple — you have one process, then machine a few holes (see below), then it goes straight to overmolding. It’s extremely efficient, which makes it cost-effective.”

The next step was how to attach the pultruded beam to the rest of the seat frame. Fasteners would add weight and also require machining a lot of holes into the continuous fiber pultruded part, reducing properties. Adhesives would add another curing step which would add to the cycle time. Ultimately, an injection overmolding step was added to the end of the process as a solution.

Injection overmolding: Process leads to design innovations

Already on board to injection mold the four main seat frame components, Flex-N-Gate was also tapped to injection overmold the beam onto the rest of the frame. Once the rest of the frame components are injection molded, the pultruded beam from L&L Products is inserted into a new mold with the rest of the completed frame. Using the same Ultramid material as the rest of the frame, injection overmolding is used over top of the beam to connect it to the frame.

However, this proved to be a complex endeavor, notes Flex-N-Gate’s Perucca, and led to design changes for the pultruded beam itself. The original hollow tube design, which was the most efficient in terms of materials use, would have been crushed under the 15,000 psi of hydraulic pressure imposed on it during the injection molding process. To prevent this kind of deformation during overmolding, the current hat section design was developed.

One unique aspect to this project compared to other overmolding applications Flex-N-Gate has done, Perucca notes, is that the overmolding serves to attach the pultruded beam to the seat back frame, but it does not serve to lock it into place. In other words, the beam still has some freedom of movement within its composite casing, to enable it to bend or react to impact against the seat — “it acts a bit like a leaf spring, in a way, absorbing the energy from an impact,” Perucca says.

Once the part itself was designed, the next step was figuring out how to secure the beam in place during molding. “Often with injection overmolding, you’re overmolding on top of metal, and then you can use magnets to hold the metal to the tool, but in this case, that wasn’t possible,” Perucca explains. Holes had to be drilled into the beam and then aligned into specially designed notches on the tool itself. These served as guides to locate and stabilize the beam in the tool and prevent the part from “floating” or shifting during molding. This, too, required several iterations in the design, Perucca explains, as the holes had to be placed strategically on areas of the beam that receive the least amount of stress in an impact event.

In part because of these challenges, near production-level tools were needed at the prototyping stage of the process, Perucca says, which posed another production challenge for Flex-N-Gate and its tooling supplier partner. Because of the safety-critical nature of the seat, all five parts — four frame components, and the overmolded pultruded beam — the part designers needed to be able to see where the weld lines from the injection molding process would be on the physical prototypes — in other words, the areas where overlaps in resin occurred during injection, which had slightly different properties than the rest of the part.

Due to the overall part complexity, Flex-N-Gate used pressure and temperature sensors in the tool during injection molding to help control the process.

Collaborative efforts, positive results

“We learned a lot through this process,” Salvia says. One of the biggest challenges was the timeline. First prototypes were developed in 2018, and 2020 was when all of the pre-production tests were done ahead of launching the 2022 model year vehicle in 2021. “As you can imagine, global events of 2020 brought new challenges to the team, especially bringing a new product to market.”

Design flexibility for maximum storage space. For some versions of the 2022 Tundra, the seat frame needed to be able to lift up and accommodate a polypropylene storage bin included underneath the rear seat. Photo Credit: Toyota

“Despite the challenges, despite the pandemic and border closures and everything else that was going on, our corporate and supplier partners never flinched,” Salvia says. “It was really incredible what our team and collaborators were able to accomplish.”

From an engineering standpoint, Toyota, BASF and the rest of the program’s collaborators have been recognized across the industry with several awards: the 2022 Altair Enlighten Award, a 2022 SPE Innovation Award in the Body Interior category, a 2022 Society of Automotive Analysts (SAA) Mobility Innovation Award in the Lightweighting category and an award for Most Innovative Material in the Production Part category of SPE’s 2022 ACCE Part Competition.

“From a customer viewpoint as well, the feedback has also been very positive so far,” Salvia says, especially regarding the additional storage capacity. He adds, “I think it’s safe to say that for future projects, Toyota is committed to researching alternative materials like structural resins and applying them to the vehicle like we did here.”

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

CFRP planing head: 50% less mass, 1.5 times faster rotation

Novel, modular design minimizes weight for high-precision cutting tools with faster production speeds.

Read MorePlant tour: A&P, Cincinnati, OH

A&P has made a name for itself as a braider, but the depth and breadth of its technical aptitude comes into sharp focus with a peek behind usually closed doors.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;width=70;height=70;mode=crop)