“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

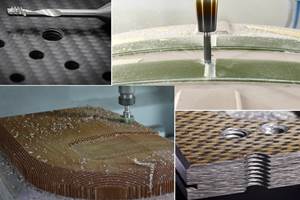

AeroZero peel-and-stick TPS (top left) is modeled for battery enclosures (bottom) and in the three models at right, comparing temperature distributions in an acrylic plate with a constant 300K applied to the bottom surface without TPS (top), with a single layer of AeroZero (center) and with the three-layer TripleZero TPS (bottom). Source (All Images) | Blueshift Materials

Technological innovations in aerospace and defense markets are redefining our understanding of mobility. Historically, government agencies and large commercial organizations (e.g., NASA, Boeing, Airbus, the U.S. Department of Defense) have invested heavily in large new vehicles, while the high cost of manufacturing prevented smaller, privatized companies from entering the industry. However, with the launch of SpaceX’s first rocket in 2008, the tide began to turn from a market controlled by only a few players, to one that has countless disrupters. This shift continues to drive innovation in spacecraft and electric aircraft, enabling a combination of lower cost technologies that have ever-increasing sophistication.

One such innovation includes technologies being developed by Blueshift (Spencer, Mass., U.S.). Established in 2013 as a deep-tech material science company, Blueshift launched its first commercial product in 2020: a family of thermal protection systems (TPS) based on an aerogel comprising 85% air and 15% pure polyimide. The TPS can be customized for a variety of thermal events (e.g., aeroheating, direct flame, contact heating). Thanks to its highly porous nature, the material can slow down the flow of thermal energy from penetrating into underlying composite structures. Its thin-profile format (starting at 7.5 mils in thickness) not only facilitates its application but frees space for additional functional layers, such as graphite and various metals, including aluminum. Branded as AeroZero, this proprietary suite of TPS products can be applied to various surfaces, including carbon fiber composites, and has already proven effective in a wide range of applications, including rockets, battery and exhaust systems and electronics.

Polyimide aerogel-based TPS

Blueshift’s technology began when a prominent electronics company encountered overheating issues. “My co-founder, Garrett Poe, worked with several groups to develop a process to make polyimide gel and then proved it at lab scale,” says Blueshift president Tim Burbey. Due to necessary funding required for scale-up, the technology took time to develop, but Poe and Burbey knew it had potential, especially in aerospace, and founded Blueshift in 2013.

Burbey describes the technology that Blueshift has now commercialized as “structured air.” It’s not a foam, he says. “Essentially what we do is package air in a way to make it more usable for product designers. It’s got a networked polymer structure, but it’s 85% air with nanosized pockets — we have more than 300 trillion air pockets in what resembles a sheet of paper.”

“And you’ve probably heard a lot about silica aerogels,” he continues, “but that is a very different product. For example, when I say structured air, that implies a material with mechanical strength. Silica aerogels do not have good mechanical strength and are not suited for high-vibration environments. And the core difference between just a polyimide aerogel and a TPS is that TPS can incorporate additional substrates — we add layers such as graphite and aluminum, or other materials that ultimately combine into a highly functional product.”

Thus, Blueshift TPS are developed to replace outdated “vintage Apollo” material solutions, enabling significantly more efficient vehicle designs with improved safety. For example, Blueshift has achieved success in extending the lifespan of standard 185°C-limited epoxy and carbon fiber composites by engineering a system that can withstand demanding transient thermal conditions ranging from -200°C to temperatures exceeding 2400°C in modern aerospace applications.

The reasoning behind “structured air”

“Air dramatically slows down the transfer of energy and temperature,” says Burbey. “Air is also radio frequency [RF] transparent, which is important for all sensors and communications in aerospace vehicles.” However, air is only one part. Polyimide, a high-temperature and chemically resistant polymer, provides a distinctive structure that helps mitigate multiple thermal transfer conditions, including conduction, convection and radiant heat.

Figure 1. (a) Conduction occurs as the result of energy transmitted due to collisions of atoms in a solid or a liquid. 300K is applied to the bottom surface.

(b) Convection is the transfer of heat from one place to another due to random motion or the bulk motion of molecules of a fluid (liquid/gas). 300K is applied to the bottom surface.

(c) Radiation result from exposure to electromagnetic waves in a certain frequency range emitted from a source. Heat is shown traveling from a 25-kilowatt infrared (IR) lamp to a silicon plate.

“Our materials aid in blocking the flow of heat/cold, regardless of the type of energy source,” explains Burbey. The skeletal structure created by the combination of air and polyimide slows incoming thermal energy and restricts its penetration rate — i.e., low thermal diffusivity. That also results in a low thermal conductivity, which means more energy per unit volume is required to alter the material’s temperature. “That combination of these properties enables our products to excel in transient thermal events,” he says. “For us, the faster rate of heat transfer and the more extreme the temperature regime is, the better. We can tailor our products to address conductive transfer, which tends to create concentrated hot spots, as well for convective energy transfer. For radiant energy, we can integrate reflective top layers, such as VDA polyimide.”

Modeling for optimization

Two additional elements of Blueshift’s capabilities include modeling and simulation. The demand for heat mitigation spans various applications with diverse conditions and requirements. These include vehicles encountering high-speed aero heating from Mach 5 to Mach 25 or during re-entry into the atmosphere, as well as battery thermal runaway and engine fires. While no single material can address every thermal issue, Blueshift combines and tailors its materials to solve niche problems for specific products and vehicle designs.

“Modeling and simulation enable us to do this,” says Burbey. “It all depends on the environment that the parts are going to see and the type of heat source — for example, radiant versus conductive heating — as well as how much space is allowed in the configuration. Will the material be in direct contact with something, or will there be a gap? The time duration is also important, as is the goal for heat reduction.

For example, let’s say you have an environment with a ~1000ºC flame, with 15 minutes of exposure. Our customers might have electronics that cannot see above 200°C, so we a can model that system to determine the best fitting product to meet their requirements.”

That solution, he adds, should not only protect the electronics, but also be lightweight and thin enough to minimize the impact on the overall vehicle or product design.

Burbey notes Blueshift also has testing capabilities, including flame testing and a wide variety of material-level thermal analyses, to validate that modeling. “More recently, we have performed an assortment of flame tests to simulate thermal runaway in battery applications,” he says. “And we’ve had to develop materials that help with molten particles and blast mitigation.”

Stacking layers

Figure 2. Blueshift tailors TPS products by stacking layers of its AeroZero material (TripleZero, top) with other materials, such as graphite, VDA polyimide, metals and more.

Blueshift tailors TPS products to fit individual applications by combining materials and stacking layers. “Our core technology is called ‘AeroZero,’” says Burbey. “Some of our products include multilayer stack-ups of this technology — for example, we have a three-layer version called TripleZero, and its thickness is roughly 20 mils [0.5 millimeter].” When creating stack-ups, Blueshift uses a proprietary high-temperature adhesive. “We can also tailor the AeroZero product, for example, adding graphite on top — which is a great heat spreader — in our AeroZero-TPS Graphite variant.” The graphite layer disperses heat along the XY-plane, while the AeroZero layer significantly slows heat penetration along the Z-plane.

“And we have a lot of choice in these superstrates that help us provide the necessary thermal protection while meeting other key requirements,” he continues. “Our standard commercial products can be provided in rolls as wide as 12 inches [305 millimeters] but we have plans to go wider. We can also slit the materials down to narrow widths of 4 millimeters.”

Peel-and-stick application, making parts

This leads to how Blueshift materials are integrated into and onto composite parts. Blueshift’s TPS line of products are supplied with a temperature-resistant, pressure-sensitive adhesive. “They are literally peel-and-stick materials,” says Burbey. “Our systems are most often applied after the composite is cured, which is great, because we don’t have to worry about how the material processes or its compatibility during molding.” He notes that Blueshift TPS can be applied to almost any substrate, provided it has sufficient preparation to provide a clean and smooth surface. Permanent bond strength is typically achieved 24+ hours after application.

The peel-and-stick aspect of the material not only greatly simplifies and quickens the actual TPS application process, but the pliancy and thin profile of the materials also offer design flexibility to engineers. “A good example is within the space industry,” says Burbey. “Amidst a push to develop more sustainable space solutions, some companies have begun creating reusable rockets for which protecting the underlying carbon fiber composite is crucial. Compared to the cork TPS solutions that was used on older space vehicles, AeroZero-based TPS involve a less labor-intensive application process that allows for an easier preparation of vehicles for launch. Plus, at a fraction of the weight of cork, our materials can perform and withstanding under the extreme temperature requirements seen during the ascent and re-entry of a rocket into the atmosphere (2400ºC for 1-2 minutes).”

Burbey notes that Blueshift makes its own polyimide resin. “It’s bespoke to what our technology needs, and that process chain extends all the way from the resin, aerogel and adhesive to stacking the various layers and cutting parts. For us, making parts means we’re cutting our TPS to fit a complex structure.” Although Blueshift materials are made in a continuous roll-to-roll format, Burbey notes most Blueshift customers are indeed buying parts. “We can provide intricate shapes and designs,” he says, citing a unique part for a lunar lander. “Our customers typically provide the shape and dimensions, and we cut our TPS using a large automated cutting table with a variety of different blades. We’ve also had projects where we actually apply our TPS on the customer’s part and then ship it back to them.”

Current and future applications

Blueshift has achieved significant success with its TPS for lightweight structures — applications ranging from electric aircraft to space vehicles/satellites to specialty medical devices. AeroZero TPS is also being used in battery box applications to mitigate the risk of thermal runaway. This need is growing due to the increasing demand for higher power density batteries. Manufacturers are developing these batteries in compact pouch or cylindrical packs, housed in small modules and then stacked to form complex systems. However, in confining the high-power density, the risk of thermal runaway increases. AeroZero TPS variants have been integrated into interior and exterior walls of battery modules and housings to help slow the spread of fire or explosion as well as temperature soak. The TPS have demonstrated effectiveness against 1000°C direct flames for up to 60 minutes with no burn-through and are being integrated into systems that are helping to promote passenger safety.

Similarly within aerospace, addressing the challenges confronting designers has significantly intensified. For example, weight savings has become more critical to enable reusable launch vehicles as well as integration of heavy, power-dense battery packs into electrified aircraft. This requires the evolution of material solutions beyond what was developed decades ago. It also requires a balance between weight, flexibility and performance.

“We founded Blueshift because we could see the technology’s potential to address these challenges and enable the ongoing revolution in mobility,” says Burbey. “We’re helping companies succeed in some of the most difficult applications, and we’ll continue to expand our capabilities and pursue even further developments to offer solutions for future composites.”

About the Author

Rebeca Velie

Rebeca Velie is the marketing manager at Blueshift (Spencer, Mass., U.S.). She has a B.A. in psychology and environmental studies from Wesleyan University where she conducted and published a peer-reviewed, data-driven research paper.

Related Content

AI-powered robotic solutions support high-mix manufacturing

AI startup offers automation innovations for high-mix, high-variability, manual surface finishing applications.

Read MoreCreating a composite battery insert-stud solution for EV trucks

Bossard worked with an OEM and Tier supplier team to meet tight electrical insulation and packaging tolerances while reducing tooling, molding and assembly costs.

Read MoreOptimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

Read MoreFiberJoints innovates composite bolted joints for reduced weight, cost and maintenance

Novel reinforcing patch uses braided sleeve to boost the load-carrying capacity of composite bolted joints.

Read MoreRead Next

AI-powered robotic solutions support high-mix manufacturing

AI startup offers automation innovations for high-mix, high-variability, manual surface finishing applications.

Read MoreCreating a composite battery insert-stud solution for EV trucks

Bossard worked with an OEM and Tier supplier team to meet tight electrical insulation and packaging tolerances while reducing tooling, molding and assembly costs.

Read MoreFastener selection for composite materials

How to navigate terminology, materials and functionality in choosing the right fastener for components or assemblies involving composite materials.

Read More

.jpg;maxWidth=300;quality=90)