Airborne, Accudyne partner to provide automated composites solutions worldwide

The two companies have signed an MOA to collaborate on further development of digital automation systems for composites manufacturing in aerospace, renewable energy, future mobility and more.

Share

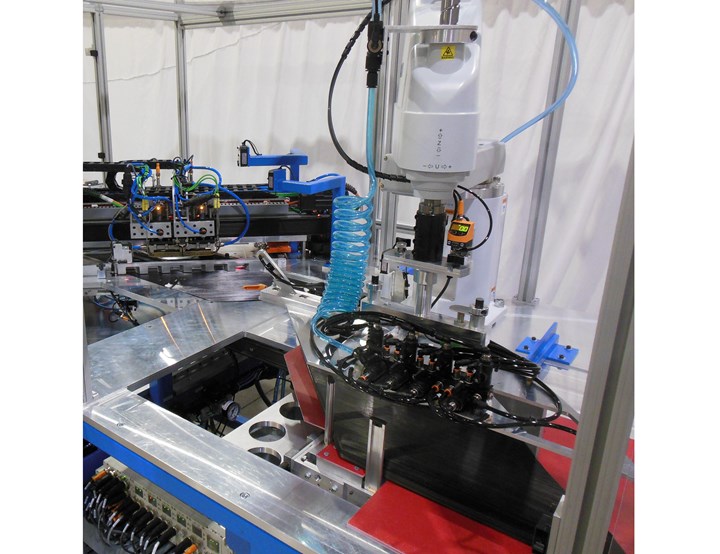

Accudyne Systems’ automated fiber placement system at Rolls Royce while Airborne has developed numerous pick and place solutions to aid in cutting, kitting and preforming operations. Photo Credit: Rolls-Royce and Airborne

Airborne (The Hague, Netherlands) and Accudyne Systems Inc. (Newark, Del., U.S.) have signed a Memorandum of Agreement (MOA) to collaborate on manufacturing solutions for composites. By joining forces, clients all over the world will have access to their expertise and unique solutions for distinctive, tailor-made automated equipment with highly specialized capabilities for automation and digitalization solutions.

Airborne and Accudyne Systems have independently introduced numerous, unique automated solutions for advanced composites manufacture. Both companies are pioneers that have operated at the forefront of composites manufacturing and automation innovation.

This collaboration leverages the complementary capabilities of both companies for system and equipment optimization, to offer a full suite of solutions in aerospace, mobility, renewables and many other industries. The growing market for composites is driven by the urgent need for lightweighting and increased sustainability. Digital automation is a key enabler, reducing cost and waste while increasing output.

A history of two pioneers

Founded in 1996 through the merger of two respected engineering firms, Accudyne Systems quickly grew into a recognized leader in the design and development of first-of-a-kind automation equipment and processes for composites, chemical separation and industrial automation. Early Accudyne employees with experience from DuPont Advanced Composite Materials Division enabled its key role in developing thermoplastic composites technologies through the 2000s (see “Consolidating thermoplastic composite structures in place”).

Accudyne Systems automated stringer former used by Qarbon Aerospace to make the horizontal tail plane (HTP) for the Gulfstream G600. Photo Credit: CW, Qarbon Aerospace, “Plant Tour: Qarbon Aerospace”

Accudyne then worked with Spirit Aerosystems (Wichita, Kan., U.S.), ATK (Salt Lake City, Utah, U.S.) and other tier suppliers to build the first thermoset composites manufacturing equipment used to produce the Boeing 787 and Airbus A350 aircraft. “There is quite a large footprint of Accudyne equipment that produces primary structure composite components for aircraft, including now for the Gulfstream G600,” explains Stephan Zweidler, director of technical sales and marketing for Accudyne Systems.

“We have built many automated forming machines for different types of stringers and stiffeners,” he continues, “as well as a lot of equipment to fabricate containment cases for large aircraft engines. For example, we built several such machines for GE Aviation’s GE90 engine production line in Batesville, Mississippi, and we also built containment case manufacturing equipment for Rolls Royce in Bristol, U.K.

Zweidler notes that Accudyne Systems’ expertise spans the entire composites manufacturing value chain and includes specialized equipment such as stringer laminating systems, cross-ply and variable-angle-ply lamination systems, thermoset and thermoplastic prepreg manufacturing lines, net-edge-of-part (pre-cure) ultrasonic robotic trim cells and much more.

Airborne was founded in 1995 by two graduate students in engineering from the Technical University of Delft (TU Delft, Netherlands). Much like Accudyne, Airborne started as an engineering company building machines and developing solutions, says Marcus Kremer, CTO for Airborne. “In 2000, we decided to focus on composites and developed technology for continuous thermoplastic composite pipes for the oil and gas industry. During that time, I was already reading papers and reports from Accudyne to learn about their fiber placement technologies, which were very impressive.”

In 2005, Airborne built a factory for serial production of continuous thermoplastic composite pipe. That company was then spun out as Strohm. Airborne then moved into composite parts manufacturing for aviation, space, marine, radio telescopes and other applications and industries. “In 2015, we decided to go back to our heritage in machine building,” says Kremers, “but this time focused on digital automation.”

Airborne’s automated ply placement system for free-shape, multi-material tailored blanks. Photo Credit: Airborne

Airborne now offers a range of automation modules including: Ply placement systems for free-shape, multi-material tailored blanks, cutting and kitting systems, edge sealing systems and turnkey automated production lines. All equipment is based on their Automated Programming software platform that eliminates manual programming and brings adaptive robotics to the shop floor.

Complimentary collaboration, vision for the future

Accudyne has a much longer history in building machines for fabricating composite parts, notes Kremers, “but Airborne has technologies that are complimentary, such as resin dispensing, potting and kitting. So, it is good that we are teaming up and also very powerful — together we offer a full spectrum of capabilities and experience. For example, we combine Accudyne’s expertise in automated stringer and stiffener forming with our focus on digital automation where the robots program themselves — what we call automated programming.”

“And that partnership is not only complimentary in terms of our capabilities and expertise, but also in terms of geography,” adds Zweidler. “Airborne has some clients in North America, and we have some clients in Europe, but both companies have been somewhat limited due to customers wanting fast, reliable supply and support. Now, customers for both companies worldwide will benefit.”

One of the projects Airborne and Accudyne are already collaborating on is an automated layup system for Siemens Gamesa’s production of offshore wind turbine blades. “It is a European customer where the brainpower of both companies has expedited the development of this bespoke machine,” says Kremers. “At Airborne, we focus more on a portfolio of modular products and invest in that while Accudyne has pursued more bespoke machines. This system for Siemens Gamesa required a new concept, and we had some ideas and building blocks, but with Accudyne we were able to build a winning proposal. I think that is a good example of what we will bring to future customers through this collaboration.”

Manufacturing and future markets

“Airborne brings great experience in manufacturing components because that was a significant part of their business for many years,” says Zweidler, “whereas Accudyne never produced parts but has invested in understanding how to make these parts in order to design and build the necessary machines for our clients. So, our companies have a complimentary view and a pretty open dialogue already established because we've been working on projects together.”

“And Airborne still manufactures parts, so we can also offer the possibility to complete initial production and ramp for the customer, handing over the automated system later,” notes Kremers. “So, that also broadens the offering.”

Kremers sees this partnership offering the new developments needed for sustainable aviation. “For example, we have multiple projects [e.g., with Solvay and Maeve] on battery enclosures for electric-powered aircraft, which will be an important market. And this also fits with the automation solutions we both provide. But you can also think about hydrogen, where Accudyne’s know-how in fiber placement will be valuable. There is also work to be done with new platforms in advanced air mobility (AAM) and in the defense sector, the latter an area where Accudyne has a long history.” (See “Airborne participates in three technology development projects for new mobility”).

Kremers also notes growth in the renewable energy market, “where we are in discussions with a number of companies. There is also a wide spectrum of applications in mobility, not just cars, but also micro-mobility including bikes, scooters, delivery vans and commercial vehicles. There's a lot of development with thermoplastics and recycled materials in this sector [e.g., the Affordable Rate-Capable Structures (ARCS) project]. Airborne is developing automation solutions that can work with these novel material formats. So that's an opportunity for Accudyne as well.”

Accudyne delivered an automated multi-module aeroengine blade manufacturing cell including automated fiber placement (AFP) and other advanced manufacturing processing equipment. Photo Credit: Accudyne, Rolls-Royce

“As decreasing composite material costs enable use beyond niche vehicles to more in the mainstream, I think there's a great possibility for Airborne’s digital automation to be used in conjunction with larger manufacturing cells,” says Zweidler. “I can see possibilities for an Airborne pick and place cell on one side with an Accudyne Systems fiber placement or other automation solution working in concert with it.”

This possibility for serial production done differently offers potential to reshore manufacturing previously moved to Asia. “We've already spoken with a company manufacturing bicycle frames,” says Kremers. “Historically, this has been done with mostly touch labor and involves challenging parts to manage in terms of their size, geometry and scale of production. It would be nice to return some of that production to Europe and/or the U.S. I think there's a great opportunity for Airborne and Accudyne to collaborate in those types of applications.”

Integrating software and hardware

“Combining Airborne’s and Accudyne Systems’ unique and complementary technologies results in exceptional solutions for composite material and component manufacturers,” says Arno van Mourik, CEO at Airborne. “Combining our strengths will bring our customers unique manufacturing solutions that will increase their efficiency and manufacturing capability, thereby significantly reducing labor and material waste.”

“The Airborne-Accudyne Systems collaboration will be a real game-changer,” says Tony Johnson, executive director at Accudyne Systems, “allowing our clients to tap into the expanded depth and breadth of expertise within our organizations across several technology domains, and giving them unprecedented access to the best automation equipment technologies worldwide. We are very much looking forward to expanding our market reach working with Airborne.”

To learn more, visit Airborne and Accudyne Systems at JEC World 2023 (April 25-27, Paris, France) in Hall 5, Booth P58.

Related Content

Collins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MorePolar Technology develops innovative solutions for hydrogen storage

Conformable “Hydrogen in a Box” prototype for compressed gas storage has been tested to 350 and 700 bar, liquid hydrogen storage is being evaluated.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreMingYang reveals 18-MW offshore wind turbine model with 140-meter-long blades

The Chinese wind turbine manufacturer surpasses its 16-MW platform, optimizes wind farm construction costs for 1-GW wind farms.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)