Airbus and CFM launch flight test demonstrator for advanced open fan architecture

Flight test demonstrator aims to mature and accelerate development of advanced propulsion technologies as part of CFM RISE program, with CFRP blades as key part of design.

Share

Photo Credit, all images: Airbus

Airbus (Toulouse, France) and CFM International (Cincinnati, Ohio, U.S.), a 50/50 joint company between GE Aviation (Cincinnati) and Safran Aircraft Engines (Courcouronnes, France), are collaborating to flight test CFM’s cutting-edge open fan engine architecture.

Joint flight-testing ambitions

The joint demonstration program will use shared flight test assets. The plan is for CFM to perform engine ground tests, along with flight test validation, at GE Aviation’s Flight Test Operations center in Victorville, Calif., U.S.

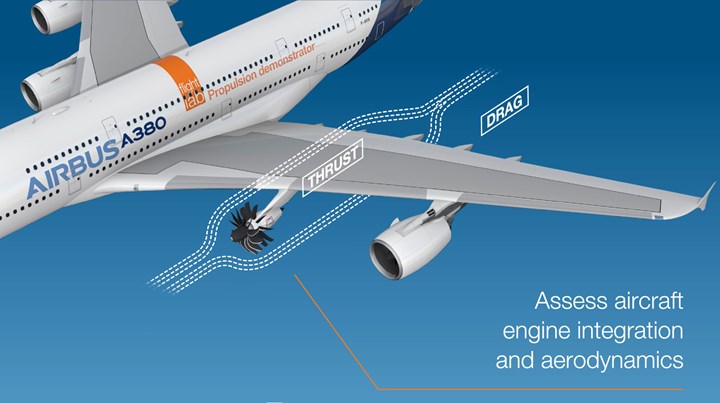

A second phase of flight tests will be performed from the Airbus flight test facility in Toulouse, France, in the second half of the decade. For these tests, the open fan engine will be mounted under the wing of a specially configured and instrumented A380 testbed aircraft.

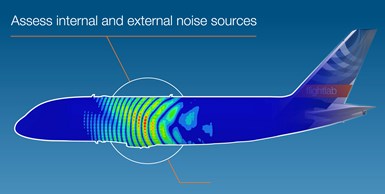

The joint Airbus and CFM objectives for the open fan joint demonstration on the A380 are extensive. The high-level goals include: evaluation of open fan propulsive efficiency and performance on an aircraft; acceleration and maturity of technologies through ground testing; assessment of aircraft/engine integration and aerodynamics (thrust, drag, loads); and evaluation of internal and external noise levels.

The goal is to achieve future engine and aircraft efficiency improvements, including propulsive system efficiency gains; improved fuel efficiency that could provide a 20% reduction in CO2 emissions compared to today’s most efficient engines and ensuring compatibility with 100% sustainable aviation fuels (SAF). Note, a reduction in CO2 emissions beyond 20% can be realized using SAF versus conventional jet fuel.

Prediction capabilities are key to find the right design that meets both the fuel efficiency and the acoustic targets (for the communities around airports and also for passengers inside the cabin). And because CFM’s engine and the wing will be very close-coupled, these capabilities have to be developed in close collaboration.

Read more about preparing the flight test hardware and evolution from two counter-rotating fans to a single plus fixed stators at “Could an open fan engine cut carbon emissions for more sustainable aviation?”

Open fan revolution and CFRP blades

In the Nov. 2021 GE Aviation blog, “Why the Time for Open Fan is Now,” GE Aviation Chief Engineer, Chris Lorence, explains the open fan’s revolution:

“It wasn’t just a breakthrough, it was radical. A single-stage fan that wasn’t simply a propeller, but rather one set of rotating fan blades with the same speed and performance of a counter-rotating fan.”

He points out that the 20% efficiency gain the open fan is geared toward is no small feat:

“The LEAP engine, introduced in 2016, is 15% more efficient than CFM56-5B and -7B engines. The GEnx engine is up to 15% more efficient than the CF6-80C2, and the GE9X engine has been designed to be up to 10% more efficient than the GE90-115B. But the push for 20% greater fuel efficiency in one generation? That is something different.”

He then includes carbon fiber-reinforced polymer (CFRP) blades as a key part of the latest design:

“Over the last 50 years, we’ve learned how to make the open fan engine design simpler and lighter. Stationary outlet guide vanes replace previous two-stage, counter-rotating fan blades in our latest designs. This change is significant because we can direct air flow and fly at speeds consistent with conventional turbofan engine architectures.

Add to that our fourth generation — and the industry’s only — carbon fiber composite fan blades, which are well suited to move to an open fan engine. No one else in the industry has the depth of expertise or composite fan experience that GE Aviation has.”

Removing the nacelle

Lorence also discusses why removing the nacelle provides efficiency gains, and how it affects the size of the CFRP fan blades:

“While ducts (or fan cases/nacelles) perform some aerodynamic function, their primary function is structural. But they weigh a ton. Literally. And when you take most of that weight away with the open fan design, you also remove propulsion drag.

We joke that removing the nacelle lets a fan blade be a fan blade. When there is a nacelle, you have to decide how big you want the fan to be. But when you remove the nacelle, the fan is able to be as big as it needs to be from an aerodynamic standpoint. Even with larger blades, the open fan is not much bigger than the nacelle we have around the CFM LEAP engine today. In fact, the blades for the RISE Program’s open fan are not much bigger than the GE9X fan blades.”

Airbus and CFM commitment

“New propulsion technologies will play an important role in achieving aviation’s net-zero objectives, along with new aircraft designs and sustainable energy sources,” Sabine Klauke, Airbus chief technical officer (CTO), says. “By evaluating, maturing and validating open fan engine architecture using a dedicated flight test demonstrator, we are collaboratively making yet another significant contribution to the advancement of technology bricks that will enable us to reach our industry-wide decarbonization targets.”

“The CFM RISE Program is all about pushing the technology envelope, redefining the art of the possible and helping to achieve more sustainable long-term growth for our industry,” Gaël Méheust, president and CEO of CFM International, adds. “CFM, its parent companies and Airbus all share the same vision and commitment for the future; the open fan flight test demonstration program is an exciting next step toward achieving the industry’s net-zero goals.”

This collaboration with CFM is just one part of Airbus’ technology demonstrator portfolio. In Feb. 2022, the two companies announced a joint flight test program to validate hydrogen propulsion capability. Airbus, CFM and CFM’s parent companies, GE Aviation and Safran, are committed to fulfilling the promise they made in signing the Air Transport Action Group goal in Oct. 2021 to achieve aviation industry net-zero carbon emissions by 2050, and developing and testing the technologies required.

Related Content

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreOne-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

The next-generation single-aisle: Implications for the composites industry

While the world continues to wait for new single-aisle program announcements from Airbus and Boeing, it’s clear composites will play a role in their fabrication. But in what ways, and what capacity?

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read More