AnalySwift receives $800,000 contract to improve composites simulation

The Phase II STTR contract from NASA, adding on to the company’s two Phase I programs in 2022, enables AnalySwift to develop and release DATEC, a design tool for engineers to design and analyze tailorable composite structures.

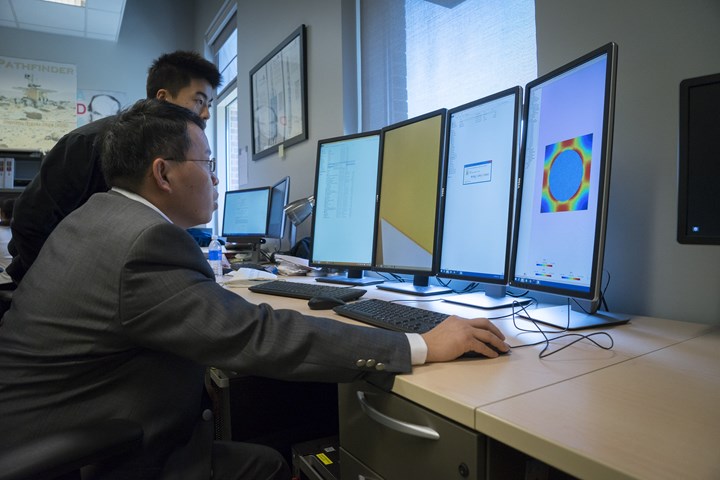

Wenbin Yu, professor in Purdue University’s School of Aeronautics and Astronautics, is seen on left. Photo Credit: Purdue University

NASA (Washington, D.C., U.S.) has awarded a $799,954 Phase II Small Business Technology Transfer (STTR) contract to AnalySwift LLC (West Lafayette, Ind., U.S.) a Purdue University-affiliated commercial software provider. The company will develop DATC (Design tool for Advanced Tailorable Composites), and launch it at the end of the 2-year contract.

Allan Wood, AnalySwift president and CEO, says advancements in simulation capabilities have not always kept pace with those in manufacturing techniques. He believes that DATC will significantly improve NASA’s capabilities to design and analyze aerospace structures made from advanced tailorable composites.

“DATC will be used to design next-generation aerospace structures, such as hybrid/blended wing bodies, space launch vehicles, space habitats and payload attach fittings,” Wood details. “These structures made from advanced tailorable composites will be lightweight and have enhanced performance.”

“Besides NASA, other related government agencies and industries will be benefit from using DATC to design better engineering systems with reduced experiments and further adjustments.”

Traditional composites consist of straight fibers in a matrix, which make predicting their properties more straightforward. According to Wood, advanced tailorable composites are not limited to straight fibers.

“These materials include tow-steered composites, in which fibers are steered along curvilinear paths instead of traditional straight paths, and variable thickness composites in which layers, often called plies, vary in thickness or drop off altogether. The materials can be reinforced with either continuous or short fibers,” Wood explains. “This customization can facilitate drastic reductions in structural weights and/or improvements in the load-bearing capacity, though the increased complexity renders it much more difficult to accurately predict their properties.”

Moreover, having a simulation tool for these materials will avoid engineers from having to rely on costly and time-consuming physical experiments instead of supplementing them with virtual testing and design.

AnalySwift will integrate several tools to create DATC. “DATC will be based on mechanics of structure genome, or MSG, and its companion code SwiftComp, which was developed at Purdue University,” Wood says. “It will also include third-party structural solver tools, a general-purpose optimizer and a machine learning package. These tools will be integrated into a unified and intuitive design framework.”

Wenbin Yu, a professor in Purdue’s School of Aeronautics and Astronautics, is the principal investigator on the development of DATC. Su Tian of AnalySwift and professor Xin Liu of the University of Texas at Arlington are co-investigators.

AnalySwift expects to complete DATC when the Phase II project ends in December 2024. “We plan to release DATC to NASA engineers and others interested in this product,” he adds. “Engineers can use DATC to create innovative, lightweight solutions for systems critical for national security, the environment, transportation, the economy and more. Besides NASA, other related government agencies and industries will be benefit from using DATC to design better engineering systems with reduced experiments and further adjustments, which lowers engineering time and cost.”

In 2022, AnalySwift received two Phase I STTR contracts from NASA, a 1-year contract for $120,000 and a 13-month contract for $156,000. The company licenses Purdue University intellectual property through the Purdue Research Foundation Office of Technology Commercialization. This work was also supported by Elevate Ventures and the Indiana Economic Development Corp.

Related Content

Improving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreThe basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreRead Next

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MorePurdue opens $41 million Hypersonics and Applied Research Facility

A dedicated 65,000-square-foot building is home to Mach 8 and HYPULSE wind tunnels to advance hypersonic evaluation and testing, and the HAMTC for materials and manufacturing work with partners.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)