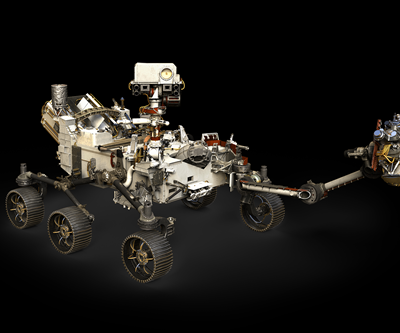

Composites-intensive Perseverance rover makes Jezero Crater milestone

Since its landing on Mars in 2021, NASA’s rover has completed four scientific campaigns. Its fifth campaign up to the crater rim, a location of geologic interest, will further aid scientists’ understanding of Mars’ past formation.

NASA’s Perseverance Mars rover used its right-front navigation camera to capture this first view over the rim of Jezero Crater on Dec. 10th, 2024. Source | NASA/JPL-Caltech

As of this December, NASA’s (Washington, D.C., U.S.) Perseverance Mars rover has crested the top of Jezero Crater’s rim at a location the science team calls “Lookout Hill” and is rolling toward its first science stop after the monthslong climb. Taking about 3.5 months and ascending 1,640 vertical feet, the rover has climbed 20% grades, making stops along the way for science observations.

The rover, supported by numerous composite materials and structures, landed in Jezero in February 2021. Since then, Perseverance has completed four science campaigns: the “Crater Floor,” “Fan Front,” “Upper Fan,” and “Margin Unit.” The science team is calling Perseverance’s fifth campaign the “Northern Rim” because its route covers the northern part of the southwestern section of Jezero’s rim. Over the first year of the Northern Rim campaign, the rover is expected to visit as many as four sites of geologic interest, take several samples and drive about 4 miles.

“During the Jezero Crater rim climb, our rover drivers have done an amazing job negotiating some of the toughest terrain we’ve encountered since landing,” says Steven Lee, deputy project manager for Perseverance at NASA’s Jet Propulsion Laboratory in Southern California. “They developed innovative approaches to overcome these challenges — even tried driving backward to see if it would help — and the rover has come through it all like a champ. Perseverance is ‘go’ for everything the science team wants to throw at it during this next science campaign.”

According to Ken Farley, project scientist for Perseverance at Caltech in Pasadena, the Northern Rim campaign brings the rover team new scientific riches as it roves into fundamentally new geology. “It marks our transition from rocks that partially filled Jezero Crater when it was formed by a massive impact about 3.9 billion years ago to rocks from deep down inside Mars that were thrown upward to form the crater rim after impact,” Farley says. “These rocks represent pieces of early Martian crust and are among the oldest rocks found anywhere in the solar system. Investigating them could help us understand what Mars — and our own planet — may have looked like in the beginning.”

With Lookout Hill in its rearview mirror, Perseverance is headed to a scientifically significant rocky outcrop about 1,500 feet down the other side of the rim that the science team calls “Witch Hazel Hill.”

“The campaign starts off with a bang because Witch Hazel Hill represents over 330 feet of layered outcrop, where each layer is like a page in the book of Martian history. As we drive down the hill, we will be going back in time, investigating the ancient environments of Mars recorded in the crater rim,” says Candice Bedford, a Perseverance scientist from Purdue University in West Layfette, Indiana. “Then, after a steep descent, we take our first turns of the wheel away from the crater rim toward ‘Lac de Charmes,’ about 2 miles south.”

Lac de Charmes intrigues the science team because, being located on the plains beyond the rim, it is less likely to have been significantly affected by the formation of Jezero Crater.

After leaving Lac de Charmes, the rover will traverse about a mile back to the rim to investigate an outcrop of large blocks known as megabreccia. These blocks may represent ancient bedrock broken up during the Isidis impact, a planet-altering event that likely excavated deep into the Martian crust as it created an impact basin some 745 miles wide, 3.9 billion years in the past.

Related Content

New GTL breakthrough in composite tubing for liquid hydrogen in aircraft and space vehicles

Tests versus stainless steel tubing show 10 times faster chill down, fuel flow in 2 seconds and less boil-off for significantly faster fueling and refueling of LH2-powered space vehicles, aircraft and trucks.

Read MoreOn the radar: Reusable launch vehicles, hypersonics make space more accessible

CFRP has become key to targeting efforts in reusing components like rocket stages, as well as the development of reusable hypersonic testbeds and spaceplanes, for increasing space commercialization.

Read MoreOn the radar: Cryogenic testing of composites for future hydrogen storage

Netherlands, U.K., France, Germany and the U.S. build up test capability, look at thermoset and thermoplastic composite materials.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MoreRead Next

Composites training firm lends a hand with Mars rover

Advanced Composites Training helps train NASA engineers in the use of composite materials for construction of the Mars 2020 rover.

Read MoreIntuitive Machines debuts moon buggy for Artemis program

IM’s Moon RACER is one of three lunar terrain vehicle (LTV) designs being considered by NASA for future operations on the lunar surface.

Read MoreAnalySwift receives NASA STTR contract to enable second-use spacecraft infrastructure

Together with Purdue, AnalySwift aims to develop a composite heater layer and a novel software tool or module to achieve assembly, disassembly of thermoplastic composite joints in space during long-duration missions.

Read More

.jpg;maxWidth=300;quality=90)