Composites mold manufacturer, BBG, is finalist for Germany’s best toolmaker 2020

Smart molds for Industry 4.0 applications key to its recognition in “Excellence in Production” competition.

Photo Credit: BBG

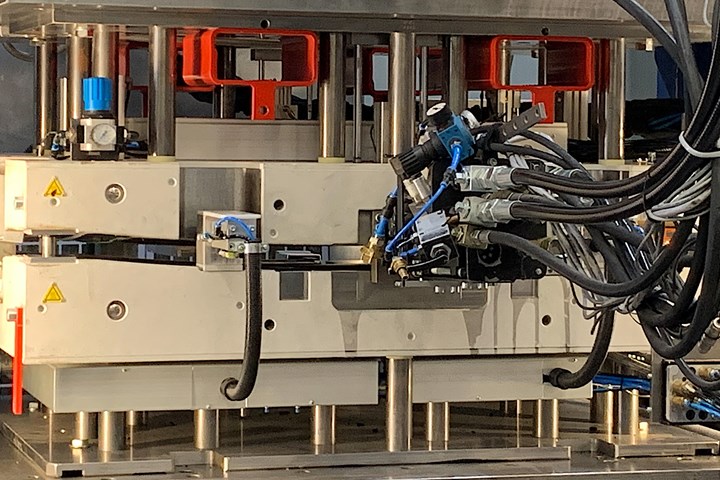

It was reported on Nov. 24 that BBG GmbH & Co. KG (Mindelheim, Germany), a manufacturer of molds, machinery and plants, presented smart molds for use in Industry 4.0 applications and in smart factory environments. The company is among the finalists in the "Excellence in Production" competition for Germany’s best toolmaker in 2020. BBG’s molds are designed and developed to process polyurethane, PVC, TPE and other elastomers, as well as a wide range of composite materials. This includes production processes such as PUR-CSM (PUR Composite Spray Molding), LFI (Long Fiber Injection), RTM (Resin Transfer Molding), SMC (Sheet Molding Compound) or GMT (Glass Mat-reinforced Thermoplastics) (see “BBG presents self-closing HP-RTM molds for CFRP compact hydrogen tank production”).

According to BBG, the smart molds, can be used, for example, in encapsulation molds for refining glass and polycarbonate sheets with polyurethane, or for manufacturing components on the basis of the PUR-RIM process. Furthermore, it is said to be suitable for all types of molds used to produce safety-relevant or Class A components that place high demands on the manufacturing process and documentation. Smart molds also facilitate fully automated production lines. Typical customers include manufacturers from the automotive, pharmaceutical, and aerospace industries, who are required to document the production data of components due their obligation to produce proof of production.

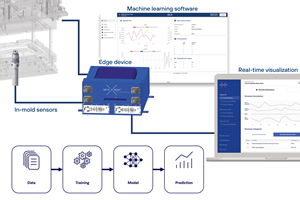

According to BBG, smart molds reduce the cost for material and energy consumption while increasing productivity and process accuracy (see “Composites 4.0: Digital transformation, adaptive production, new paradigms”). In addition, the process data required for documentation can be gathered for every component and can be stored long-term. To this end, the molds are equipped with a large number of sensors that collect data on process parameters such as temperature, flow velocity and pressure during the entire manufacturing process. Special sensors developed by BBG are also able to detect metallic inserts in steel molds reliably, ensuring validated measurements even with the panes inserted.

Further, BBG says information can be processed on-site at the mold or forwarded to the higher-level control systems of other production lines. Any deviations from the target values specified are displayed and can be corrected immediately. Furthermore, the correct sequence and the performing of work steps can be specified and can be controlled by the mold itself. In this way, an operator always knows that the work steps have been carried out correctly in the specified order, and which ones will be next.

The data collected in intelligent molds can be processed and displayed directly on-site or forwarded to the control systems of other production lines, such as mold carrier systems or encapsulation equipment. Photo Credit: BBG

“Smart molds are at the top of our wide range of products, which starts with simple and cost-efficient prototyping molds,” says Hans Brandner, the managing partner. “What the customer needs is what counts for us. We develop the right mold customized to meet every requirement.”

According to Brandner, BBG’s strict focus on customer benefit is also key for the renewed success at the "Excellence in Production" competition. BBG has been nominated this year for the second time after 2018, as one of the best toolmakers in Germany. In the category "External toolmaker with fewer than 50 employees,” BBG once again made it to the top three. The winner was announced at the online award ceremony on Nov. 18.

“Excellence in Production" is organized by the Werkzeugmaschinenlabor WZL of the Rheinisch-Westfälische Technische Hochschule (RWTH) and the Fraunhofer Institute for Production Technology, which are both headquartered at Aachen,Germany. Around 300 specialized companies and in-house corporate departments regularly participate in the competition, which has been organized every year since 2003, and compete against each other in four different categories.

Related Content

Next-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

Read MorePlant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

Read MoreNew Frontier Technologies launches digital twinning, high-fidelity simulation capability

3D imaging and analysis capability illustrates detailed, quality characterization and performance simulation of composites and other advanced materials that properly captures the as-manufactured component.

Read MoreUltra high-rate composite deposition system trials to surpass layup targets

The NCC, alongside partners Loop Technology, Coriolis and Güdel, are on track to deliver dry fiber deposition rates exceeding 350 kilograms/hour, seven times more than standard aerospace rates.

Read MoreRead Next

CFRP planing head: 50% less mass, 1.5 times faster rotation

Novel, modular design minimizes weight for high-precision cutting tools with faster production speeds.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.

Read More

.jpg;maxWidth=300;quality=90)