European SUSPENS project targets green composites production

The 13-partner program will addresses the challenge of reducing the environmental footprint of sandwich and hollow composite structures via bio-sourced resins and carbon fiber precursors.

IRT Jules Verne’s kick-off meeting of SUSPENS, which took place in Nantes, France. Photo Credit: IRT Jules Verne

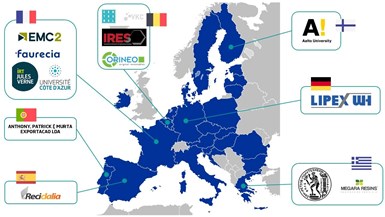

On Jan. 27 SUSPENS was launched, a €4.9 million ($5.3 million), 3.5-year European project coordinated by IRT Jules Verne, a research institute based in Bouguenais, France. Aided by 13 partners (mentioned below), SUSPENS will tackle the challenge of reducing the environmental footprint of sandwich composite and hollow structures manufacture for the automotive, nautical leisure and aeronautics industries.

To achieve this, the program will focus on replacing carbon fiber-based composites — which use fossil-related resources to manufacture — with more natural and sustainable bio-sourced alternatives. The consortium will be doing this in a couple of ways: (1) through the study of bio-sourced resins and (2) determining whether lignin — a woody matrix derived from the cell walls of plants — could replace polyacrylonitrile (PAN) as a carbon fiber precursor. For the latter, according to an Aviation Week report on the subject, the “priority in SUSPENS is to ensure that the resulting carbon fiber performs as well as conventional fiber manufactured from PAN.” This is particularly important for aerospace-grade composite materials, which must reach “a glass transition temperature (Tg) high enough to avoid the deterioration of mechanical performance.”

According to Mehdi Marin, head of the SUSPENS program at IRT Jules Vernes, 95% of bio-sourced resins could be synthesized from flax, rape, castor oil or algae. SUSPENS, is particularly focused on bio-sourced epoxy and polyester thermoset resins. These resins will be combined with durable reinforcements based on natural fibers (cellulose), carbon fibers derived from lignin and recycled carbon fibers. SUSPENS hopes by studying changes to the resin’s chemical composition and behavior, they will be able to shorten the curing time.

Together, these developments will be demonstrated via an automotive battery box, a hull for a pleasure boat and a wing appendage (winglet). As an additional measure, the consortium will be developing novel processes to address more sustainable production and recycling at end of life. An innovative pyrolysis approach will attempt to drastically reduce energy consumption during carbon fiber production. In parallel, a solvolysis process for the bio-sourced resins will be developed to recover the constituents of the matrix and isolate the reinforcement, to be manufactured into new resin products. A life cycle analysis (LCA) will complement this full-cycle environmental demonstration by measuring cradle-to-cradle footprint gains for the three applications.

Specifically, IRT Jules Verne will be in charge of the development of the hollow part or sandwich-type demonstrators, which will be produced by one-shot manufacturing processes using bio-sourced and recycled materials. IRT Jules Verne will also be in charge of promoting and disseminating the results.

SUSPENS is one of many recent attempts to achieve more climate-conscious composite materials production. Aeroflax, an aerospace-grade flax fiber-based prepreg pitched by Lufthansa Technik (Hamburg, Germany) uses vegetal fiber and a bio-based resin; it has been demonstrated in interior cabin components. The Chemnitz University of Technology (Germany) has received a grant to research the entire value chain, from raw material extraction and processing, through materials and processes, in an effort to expand research into “green” carbon fiber. CW also reported on developments in 100% bio-based thermoset resins that are suitable for space applications. (Also keep an eye out for CW’s upcoming March WIP addressing developments being made in the sustainable precursor space, mentioned above.)

The SUSPENS project is co-funded by the EU’s Horizon Europe program European Union.

Related Content

Hexagon Purus Westminster: Experience, growth, new developments in hydrogen storage

Hexagon Purus scales production of Type 4 composite tanks, discusses growth, recyclability, sensors and carbon fiber supply and sustainability.

Read MoreCirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MorePlant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)