Hexagon Purus extends agreement for hydrogen distribution systems, raises 1 billion NOK

Agreement with green hydrogen producer extended for 2024, investment will support ongoing global capacity expansions including CFRP cylinder production.

Hexagon Purus hydrogen distribution module using Type 4 carbon fiber-reinforced polymer (CFRP) pressure vessels and the company’s cylinder production site in Kassel, Germany. Photo Credit: Hexagon Purus

Hexagon Purus (Oslo, Norway) has extended its existing framework agreement (announced October 2022) with a leading European producer of green hydrogen to include delivery of hydrogen distribution systems for 2024. Hexagon Purus’ hydrogen distribution systems, with its Type 4 composite cylinders, will be used to deliver green hydrogen for mobility and industrial applications in Europe. The minimum value of the framework agreement is approximately €17 million. The hydrogen systems will be manufactured in Hexagon Purus’ facility in Weeze, Germany, with delivery scheduled starting in Q1 2024.

“The demand from our customers is strong and there is a trend towards securing future build slots by entering into long-term framework agreements, a trend that we expect to further accelerate as green hydrogen becomes increasingly available,” says Michael Kleschinski, EVP of Hexagon Purus. “We are happy to extend the current agreement to support the distribution of green hydrogen to European mobility and industry applications.”

According to Hexagon Purus, the industrial and mobility sectors account for close to 50% of annual carbon emissions globally, and hydrogen has an important role to play in reducing these emissions, particularly in hard-to-abate sectors. Hexagon Purus reports that its hydrogen transport modules, based on Type 4 carbon fiber-reinforced composite cylinders, offer the highest capacity and lowest total cost of ownership compared to traditional steel tube trailers. Hydrogen is projected to supply up to 25% of the world's energy needs by 2050.

New capital raise of 1 billion NOK to ramp capacity

Hexagon Purus has also raised ≈1 billion NOK (≈ €88.5 million) from strategic investors Mitsui and Hexagon Composites. These are joined by Hy24, said to be the world’s largest clean hydrogen pure-play investor, through its newly raised Clean Hydrogen Equipment Fund. These three investors bring access to knowledge and networks across the hydrogen and mobility value chains.

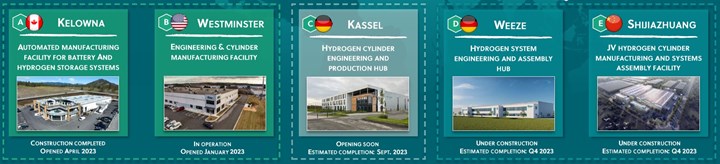

This capital raise was announced by Hexagon Purus on Dec. 23, 2023 and approved at an Extraordinary General Meeting on Jan. 11, 2024. The proceeds will support Hexagon Purus’s growth strategy, including its ongoing global capacity expansion. Hexagon Purus notes 2024 will be an important year to ramp up capacity at its five newly opened facilities:

- Westminster, Md., U.S. (cylinders)

- Kelowna, BC, Canada (batteries, systems)

- Kassel, Germany (cylinders)

- Weeze, Germany (systems)

- Shijiazhuang, China (cylinders, systems)

Photo Credit: Hexagon Purus Q3 2023 presentation

The company is also planning to open a new site in Dallas, Texas, in 2024 for integration of its battery electric systems into zero-emission buses, trucks and commercial vehicles.

“We operate in an increasingly supportive regulatory environment with large investments being made into renewable energy generation and hydrogen to support the clean energy transition,” says Morten Holum, CEO of Hexagon Purus. “This capital raise ensures that we can continue to scale up our manufacturing capacity to deliver on existing customer contracts for hydrogen infrastructure and prepare for serial volume of zero-emission mobility as demand increases.”

Related Content

-

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

-

Hexagon Purus opens new U.S. facility to manufacture composite hydrogen tanks

CW attends the opening of Westminster, Maryland, site and shares the company’s history, vision and leading role in H2 storage systems.

-

ECOHYDRO project to enable recyclable composites for hydrogen storage

With the involvement of two schools from the Institut Mines-Télécom, the 4-year project aims to improve the intrinsic properties of a composite material based on Elium via four concrete demonstrators.