NASA orders three additional Orion spacecraft from Lockheed Martin

Lockheed maintains an OPOC for up to 12 composites-intensive vehicles over the course of the Artemis moon missions, reduces cost by 50% per vehicle.

The Orion crew module pressure vessel for the Artemis III mission — the first vehicle under the Lockheed Martin OPOC contract — is undergoing assembly at NASA’s Kennedy Space Center. Photo Credit: Lockheed Martin

Lockheed Martin (Bethesda, Md., U.S.) is now under contract to deliver three Orion spacecraft to NASA (Washington, D.C., U.S.) for its Artemis VI-VIII missions, continuing the delivery of exploration vehicles to the agency to carry astronauts into deep space and around the moon.

Lockheed Martin is the prime contractor to NASA for the Orion program and has completed two Orion vehicles — EFT-1 which flew in 2014, and Artemis I, which is weeks away from its launch to the moon — and is actively building vehicles for the Artemis II-V missions. Created by Lockheed Martin engineers, the Orion spacecraft relies on a composite heat shield design (see “Orion re-entry system: Composites displace metal”), and a thermal protection system (TPS) made from Avcoat ablative materials, “pre-machined to fit into their positions and bonded in place on the heat shield’s carbon fiber skin” (more information here). Airbus’ (Toulouse, France) European Service Module (ESMs), providing propulsion, power and thermal control to the spacecraft, also boasts a composite design.

“Lockheed Martin is honored to partner with NASA to deliver Orion spacecraft for NASA’s Artemis missions. This order includes spacecraft, mission planning and support, and takes us into the 2030s,” Lisa Callahan, vice president and general manager for Commercial Civil Space, Lockheed Martin, says. “We’re on the eve of a historic launch kicking off the Artemis era and this contract shows NASA is making long-term plans toward living and working on the moon, while also having a forward focus on getting humans to Mars.”

This order marks the second three missions under the agency’s Orion production and operations contract (OPOC), an indefinite-delivery, indefinite-quantity (IDIQ) contract for up to 12 vehicles. A breakout of these orders includes:

- 2019: NASA initiates OPOC IDIQ and orders three Orion spacecraft for Artemis missions III-V.

- 2022: NASA orders three additional Orion spacecraft missions for Artemis VI-VIII for $1.99 billion.

- In the future: NASA can order an additional six Orion missions.

Under OPOC, Lockheed Martin and NASA have reportedly reduced the costs on Orion by 50% per vehicle on Artemis III through Artemis V, compared to vehicles built during the design and development phase. The vehicles built for Artemis VI, VII and VIII will see an additional 30% cost reduction.

“We're achieving substantial cost savings from Artemis III through Artemis VIII by extensive structure and system reuse and incorporating advanced digital design and manufacturing processes,” Tonya Ladwig, Orion vice president and program manager at Lockheed Martin Space, adds. “The Artemis II vehicle will reuse select avionics from the Artemis I crew module, and that reuse will continue to dramatically increase to where the Artemis III pressure vessel capsule will be entirely refurbished for the Artemis VI mission.”

Additionally, the company says it will drive out cost from these production vehicles through material and component bulk buys from suppliers and an accelerated mission cadence.

With the Artemis I Orion spacecraft currently on top of the Space Launch System (SLS) rocket, there are two other Orion vehicles undergoing assembly at NASA’s Kennedy Space Center in Merritt Island, Fla., Artemis II and III. Work is well under way on the Artemis IV craft, including welding the pressure vessel together at NASA’s Michoud Assembly Facility near New Orleans, and the heat shield at Lockheed Martin’s facility near Denver, Colo.; work has already begun on the Artemis V vehicle.

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreRead Next

Beyond Gravity delivers space technology, composites expertise for Artemis missions

Mechanisms to drive solar array panels, a composite universal stage adapter and central network electronics supply drive Artemis missions forward.

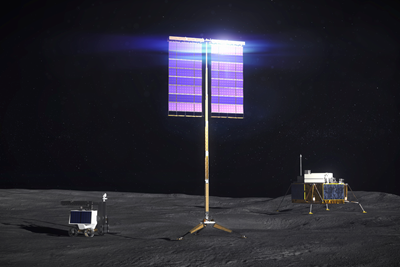

Read MoreThree companies chosen to advance NASA deployable solar array

Astrobotic Technology, Lockheed Martin and Honeybee Robotics awarded $19.4 million to prototype build and test solar array systems to power moon exploration under Artemis. Current mast designs incorporate carbon fiber-based technologies.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)