ORNL demonstrates lightning strike protection tech for composites

Researchers, led by Vipin Kumar, developed a low-cost, recyclable carbon fiber wind turbine blade tip that showed resilience to high-voltage lightning strikes, with more innovations in store.

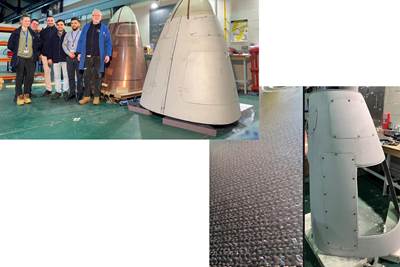

ORNL researchers and technicians prepare to remove the wind blade tips from molds where glass fibers were cured with layers of ORNL carbon fiber. Source | Carlos Jones/ORNL, U.S. Dept. of Energy

Researchers at the Department of Energy’s (DOE) Oak Ridge National Laboratory (ORNL, Tenn., U.S.) have been brainstorming a series of technologies to prevent lightning damage to the composites used in wind turbines and aircraft. Led by Vipin Kumar, ORNL has reached a significant milestone by building an entire 6.5-foot turbine blade tip using novel materials. The team then tested it against the forces of simulated lightning in a specialized lab at Mississippi State University.

The blade tip emerged pristine after tests that isolate the effects of high voltage. Separate tests in the same lab found that isolated high current remained destructive. But Kumar is striking back with further innovations. ORNL’s recent demonstration highlighted the possibilities of a new approach to protecting blades using conductive materials or coatings.

Although lightning often hits wind turbines, its broader impact on the wind industry remains unclear. Lightning strikes to turbine blades are frequent but rarely catastrophic. They can nevertheless weaken blades with internal damage that translates to increased repair costs over time. For example, lightning strikes are the second leading cause of blade-related downtime, Kumar says. “We don’t have enough data to know the true scope of the challenge, but we know it’s a concern to industry and utilities. We know wind energy is a reliable source of electricity that supports energy security, but I believe anything we can do to make it more resilient and reliable is important.”

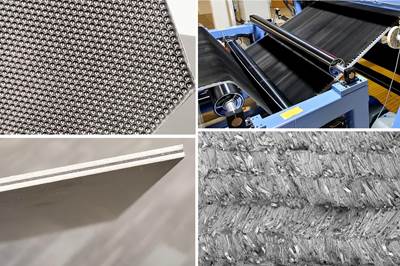

The project combined Kumar’s expertise in composites with ORNL’s capabilities in carbon fiber. The blade tip, made at ORNL in DOE’s Carbon Fiber Technology Facility, incorporated two layers each of standard glass fiber and a low-cost carbon fiber developed at the lab. In this case, customized conductive carbon fiber is key to dispersing electrical energy across the blade surface. Researchers then used industry-standard equipment and methods to show the technology can be easily integrated with established manufacturing processes.

ORNL researcher Vipin Kumar, an expert in lightning strike protection for airborne composites, inspects the wind turbine blade tip before he and his team remove it from a mold at DOE’s Carbon Fiber Technology Facility. Source | Carlos Jones/ORNL, U.S. Dept. of Energy

Kumar explains that the cost of carbon fiber has generally limited its use to the wind blade’s load-bearing structure — the spar cap. But ORNL’s efforts to lower the cost of carbon fiber may make it economical to replace glass fibers in the blade tip, where lightning strikes most often. “This is a stepping stone in the right direction,” says Merlin Theodore, who leads the Advanced Fiber Manufacturing group at ORNL. “We were happy to show this could be done at scale. Although there is more work to be done, this shows that carbon fiber has a more significant role to play in wind energy applications.”

ORNL’s turbine blade tip, which is fully recyclable, recently won an ACE award for Composites Excellence in the category of “innovation in green composites design” from AMCA. “We have a plan to show the complete recyclability of this blade by reusing the carbon fiber and reusing the resin for 3D printing in the Manufacturing Demonstration Facility at ORNL,” Kumar says.

An electrifying career

Kumar’s career, which began in 2018 with postdoctoral research at ORNL, has been a relentless search for ways to protect airplanes, drones and wind turbines from lightning that threatens structural integrity and reliable electricity. “I’m trying to save anything in the sky made of a composite from lightning damage,” he says.

Carbon fiber’s strength makes it the exclusive choice for airplane composites, but it’s also semi-conductive. “To protect composites from lightning damage, you have to actually increase its conductivity,” Kumar explains. “You cannot rely on insulating it or directing lightning to specific locations.”

The wind industry has tried that approach by using a metallic receptor attached to a rod in the blade, like a lightning rod under the surface, to transport electricity to the ground. However, the rod doesn’t always draw the current when lightning strikes the composite material. “While other wind turbine technologies have evolved significantly in recent decades, the industry’s approach to lightning strike protection has not advanced as quickly,” he notes.

For increasing conductivity, Kumar has used different materials, such as a conductive external coating or a matrix of carbon nanofillers, to create a conductive “skin” that dissipates energy, preventing burning or interior damage at the strike point. Kumar’s experiments, each tested in a lightning lab, produced continuous improvements that culminated with a compression-molded composite using many layers of low-cost carbon fiber. “I didn’t expect it to perform as well as it did,” Kumar said. “I tested it against five lightning strikes that were six times stronger than the average bolt: No damage. I started scratching my head, asking why.”

Kumar learned that ORNL’s carbon fiber could be customized for greater conductivity, inspiring him to test it in an entire blade tip.

Meeting future wind generation needs

Demand for carbon fiber, a mainstay of the aerospace industry, is expected to outpace supply within five years, further driving up its cost. ORNL believes its more economical formulation could enable the wind industry to afford to compete for the material, says ORNL researcher Subhabrata Saha, who led creation of the blade tip. “It can help match today’s cost while providing higher strength per weight of the blade.”

The hybrid carbon fiber composite blade tip is 41% lighter than a blade tip made with pure glass fibers, Kumar adds. “That means we can make bigger blades of the same weight that generate more electricity.”

A wind turbine blade tip made using ORNL-developed carbon fiber emerged pristine when tested in a lab against high-voltage jolts of simulated lightning. Source | Vipin Kumar/ORNL, U.S. Dept. of Energy

Doubling the length of a turbine blade enables it to generate four times more power, leading to blades that are sometimes over a football field long. This significant size increase allows for more energy output from modern wind turbines. “But the larger the blade, the larger the chance it will be hit by lightning,” Kumar adds.

The blade and a set of smaller composite panels, created simultaneously from the same material, underwent separate tests for voltage and current to simulate lightning’s destructive forces. Current is the rate at which electricity flows, and voltage is essentially the force that drives the electricity between two points. High-voltage tests are used to understand the lightning attachment entry and exit locations, while the resistive heat of high-current tests is more destructive to the composite laminate.

Kumar’s team then used ultrasonic imaging to assess any damage to the material. The full wind blade tip emerged pristine from high-voltage bolts of electricity but did not hold up as well to blasts of intense current. However, the prototype sample panels suffered no visible or internal damage and retained their mechanical properties, demonstrating “remarkable resilience” to lightning strikes, Kumar says. The same test blasted a hole in a panel made with standard commercial carbon fiber.

Why did the ORNL test panels perform better than the full blade tip, despite being made of the same material? One potential cause is that the panels were compression molded, which created a higher volume of carbon fiber in the composite. They were also heat-cured, while the blade tips were allowed to set at room temperature. Heat-curing improves the material by using heat to strengthen its structure and enhance its thermal properties and performance.

But Kumar isn’t counting on an easy solution. Because the resin makes up the largest portion of the blade tip, he wants to experiment with using a more conductive resin. Moreover, an affordable, versatile coating can be made from the nanofillers in polymer. Even without the carbon fiber, panels with this coating performed well in recent voltage and current tests, according to Kumar.

Kumar explored the economic viability of his research as part of DOE’s 2024 Energy I-Corps program, which helps national laboratory scientists identify pathways for bringing their innovations to market. Kumar interviewed 82 wind industry professionals, including turbine blade manufacturers, wind farm operators and blade repair companies, to learn more about their challenges and what solutions they’d embrace. His nanofiller coating sparked the most interest. Kumar is talking with potential industry partners about field testing it at a wind farm where its effectiveness can be monitored over time.

The research is funded by the Advanced Materials and Manufacturing Technologies Office within DOE’s Office of Energy Efficiency and Renewable Energy.

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

Future Fibres’ LiMit Collar protects composite rigging against lightning

Multi-material system wins DAME Design Award 2023 for mitigating damage caused by direct or induced lightning currents to carbon fiber and metallic mast rigging for watercraft.

Read MoreD-JOINTS project helps engineers protect composite aircraft structures from lightning strikes

Design of innovative composite hybrid joints with electromagnetic compatibility project tested and validated two types of joint technologies plus software tool for faster design.

Read MoreZ-direction composite properties on an affordable, industrial scale

Boston Materials uses milled reclaimed carbon fibers to increase modulus, impact/delamination resistance and produce metals-like conductivity for EMI shielding, lightning strike protection, heat exchangers and more.

Read More

.jpg;maxWidth=300;quality=90)