Purdue, Wabash National collaborate on composite trailer that recaptures its own energy

An experimental trailer that harvests its own electricity from vibrations, heat and airflow is anticipated to make trailers worldwide more sustainable and energy-efficient.

Senior leadership from Purdue University and Wabash gathered at Herrick Labs on April 30, 2024, to kick off this collaborative research project. Source | Purdue University/Jared Pike

Purdue University (West Lafayette, Ind., U.S.) researchers have teamed up with trailer manufacturer Wabash National Corp. (Lafayette) to investigate an experimental trailer — one made of composite materials — that recaptures its own electricity from vibrations, heat and airflow. “In this age of sustainability and finding new ways to reduce carbon in our environment, nothing could be more visionary than a trailer that uses composite matrix materials to create its own electricity,” notes Brent Yeagy, president and CEO of Wabash.

The donated trailer is part of a 3-year collaborative research project between Wabash and Purdue University’s College of Engineering. First experiments will take place at the university’s Herrick Labs.

“We’re investigating several ways to harvest electricity from a trailer’s normal operation,” says James Gibert, associate professor of mechanical engineering and one of the project’s principal investigators. “These modalities could be the vibration of the suspension system, aeroelastic vibrations of the composite panels or harvesting the air used in the braking system.”

Gibert’s field of expertise is smart materials, especially in the realms of dynamics and vibration. His previous work has included embedding triboelectric generators into cardboard packaging, whose natural movement during the delivery process generated enough electricity to power sensors embedded in the boxes. Scaling up that process to something the size of a semi-trailer is the next logical step.

Tractor-trailers carry nearly 72% of the country’s freight.

“The scale is much bigger than anything we’ve worked with before,” notes Gibert. “But that’s a good thing. A semi-trailer has lots of mass, which means lots of opportunities for that mass to be utilized in ways it hasn’t before. Plus there’s an increasing regulatory push for these vehicles to be more energy-efficient. We are trying to get a step ahead of that, and think outside the box for what a novel energy-harvesting system could look like.”

Phase one of the project involves retrofitting the trailer with displacement sensors, accelerometers, anemometers, pressure gauges and many other measurement tools. After Gibert and his team at Herrick Labs have turned the trailer into a mobile data acquisition system, Wabash personnel will take the truck onto the highways of Indiana for some short-haul and long-haul test drives. Once the Purdue team have collected data from the test drives, they plan to coalesce around the energy-harvesting methods that are most promising. In the final phase, Purdue and Wabash will collaborate on a deliverable product that can be scaled up and deployed to trailers around the world.

How much energy can you harvest from a trailer’s own vibrations? That’s tough to say before the experiments start. But Gibert says that reducing a tractor-trailer’s electrical load, even by a little bit, is a success. “By diversifying the load, we can reduce the size of the batteries required,” he says. “Lighter batteries means less weight, which leads to even more efficient operation. So it becomes a positive feedback loop.”

The other principal investigators from the Purdue side are Andres Arrieta, associate professor of mechanical engineering; Greg Shaver, director of Herrick Labs and professor of mechanical engineering; and John Evans, assistant professor of agricultural and biological engineering.

“Purdue is a natural choice for us to collaborate with,” says Yeagy, who holds a Bachelor of Science in environmental engineering science and a Master of Science in safety engineering from Purdue University. “They’re located right across the river, and they are a leading engineering school. We couldn’t ask for a better partner to help bring these innovations to life. That trailer sitting in Herrick Labs means we’re hopefully on the verge of something we can deploy at scale.”

Related Content

TPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

Read MoreRead Next

The long view for composites in long-haul trucks

Composite components on heavy trucks and trailers continue to grow, both in volume and in kind, but they won’t be carrying structural loads until the mid-2020s.

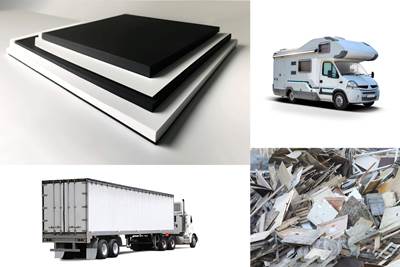

Read MoreA new generation of PP foam core for lightweight truck trailers, RVs

Extruded PP (XPP) foam core offers lightweight, high-performance monomaterial panels that are easily recycled for truck flooring, sidewalls or cabinet/furnitureboards as the transportation industry seeks a replacement for plywood.

Read MoreRefrigerated railcar floor expands composites horizons

TrinityRail, in an effort to update a 20-year-old design, seizes the opportunity to apply composites in a structural application in its refrigerated railcar. It’s a first for the rail and composites industry.

Read More

.jpg;maxWidth=300;quality=90)