Resin-infused center console boat configuration proves higher performance, speed, quality

Hayaari Marine employs a revised infusion setup using semi-permeable membranes to eliminate porosity and improve laminate consolidation, reducing about 450 kilograms of resin per boat, and offering 20% weight savings.

Flagship center console boat model, H:CRAFT H44Z. Photo Credit, all images: Hayaari Marine

Motorboat builder Hayaari Marine (Abu Dhabi, United Arab Emirates) has recently launched a fully resin infused version of its flagship center console boat model, the H:CRAFT H44Z, with weight savings of more than 20% enabling a top speed in excess of 90 miles per hour.

Hayaari Marine says it has seen major benefits with the switch to infusion, saving approximately 450 kilograms (~992 pounds) of resin per boat and reducing the overall hull weight by more than 20%. The investment in infusion technology has also increased the laminate quality and consistency, as well as provided for cleaner, safer shop floor conditions with reduced volatile organic compound (VOC) emissions.

Working with a novel, in-house designed, glass-topped infusion test table, Hayaari’s engineering and production team evaluated flow speed and resin consumption for multiple laminate and consumable configurations. The optimum combination selected for series production uses Scott Bader’s (Wellingborough, U.K.) Lloyds-approved Crystic VE679-03PA infusion resin and Crystic gelcoat, glass fiber stitched multiaxial fabrics, PVC foam cores and what is said to be the latest in vacuum consumable technology.

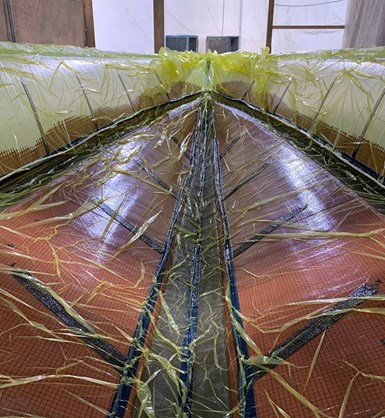

The resin infusion process.

Taking inspiration from the aerospace sector, Hayaari Marine also uses semi-permeable membranes to enhance the infusion process. By allowing air to pass, yet blocking the passage of resin, the semi-permeable membranes maintain the vacuum after the infusion is complete, eliminating porosity and improving the consolidation of the laminate.

Hayaari’s revised infusion setup requires only seven resin inlet points for the 44-foot hull, reducing the risk of air leaks and simplifying the resin management throughout the infusion. As well as the hull, Hayaari also uses the resin infusion process to manufacture the H44Z floor, cap deck, console, seats and roof.

According to Hayaari, the standard H44Z E-glass and infused vinyl ester construction delivers optimized performance. Further upgrades are also available, with Hayaari offering a carbon fiber and epoxy version of the H44Z for owners looking for the ultimate lightweight and high-performance center console boat.

“At Hayaari Marine, we have always focused on the highest quality raw materials,” comments Wassim El Zein, owner, Hayaari Marine. “With the H44Z switch to infusion, we created our own in-house testing tools to really understand how these materials interact with the vacuum consumables. The results speak for themselves. Exceptional laminate quality, a 20% weight reduction of unnecessary resin, and a 90-plus mile per hour top speed.”

The H:CRAFT H44Z will be on display at stand 620 in the water at the Miami International Boat Show at the Sea Isle Marina from Feb. 16-20, 2022, by U.S. distributor, Manatee Marine Unlimited (Palmetto, Fla., U.S.).

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.