Synthesites, Purdue CMSC advances real-time cure monitoring

Partners are developing cure simulation using data from dielectric sensors to monitor infusion and autoclave composite structures in real time.

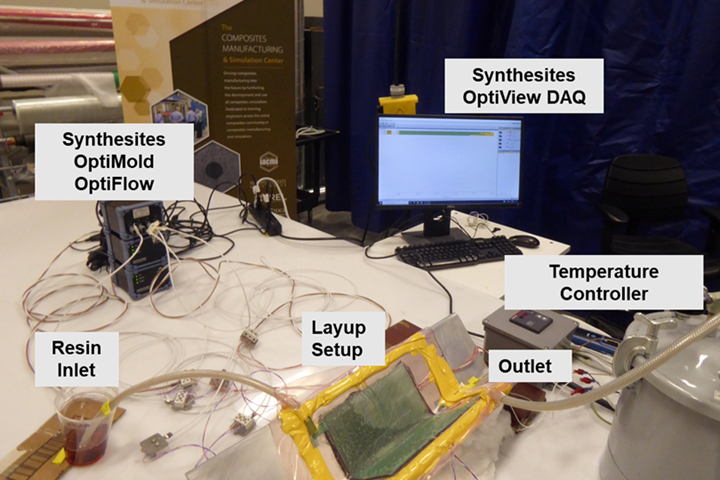

Experimental setup at Purdue CMSC for vacuum-assisted resin transfer molding (VARTM) process of L-Beam using EPON 862/W. Photo Credit, all images: Purdue CMSC, Synthesites

Researchers from Purdue University’s (West Lafayette, Ind., U.S.) Composites Manufacturing & Simulation Center (CMSC) are collaborating with Synthesites (Uccle, Belgium) to advance real-time cure monitoring of liquid composite molding and autoclave composites manufacturing processes. Together, the partners are developing cure simulation using data from dielectric sensors and predicting deformation and spring-in of the composite structures. Through the Synthesites monitoring system, the CMSC researchers are able to track resin flow, viscosity and glass transition temperature (Tg), as well as optimize the curing process and implement process control.

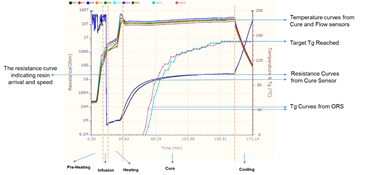

Purdue CMSC researchers use the resin flow sensors for monitoring resin arrival and temperature at different critical sections of the composite part. Cure sensors are employed to track curing at the two main critical regions of the resin inlet and outlet. Further, these data are coupled with the cure-processing models to make accurate predictions about the deformation and spring-in of the manufactured composite structures.

Results from this work will be discussed at CAMX 2022 by Dr. Dianyun Zhang, assistant professor at Purdue University School of Aeronautics and Astronautics, in the presentation, “Cure Process Modeling and Characterization of Composites Using In-Situ Dielectric and Fiber Optic Sensor Monitoring,” on Wednesday, Oct. 19 at 11:00 a.m. in the Anaheim Convention Center, Room 209A.

The CMSC is a bridge between the academic and industrial communities, connecting the global composites industry and Indiana manufacturing to Purdue University. CMSC research is driven by industry needs and grounded in academic rigor. Global sponsors and partners include aerospace and automotive OEMs, Tier 1 and 2 suppliers, materials suppliers, wind turbine manufacturers and commercial software providers. The CMSC is a collaboration of the College of Engineering and the Purdue Polytechnic Institute and is a Purdue University Center of Excellence. State-of-the-art manufacturing and characterization facilities provide a one-stop shop for composites design, manufacturing, prototyping and model validation. The CMSC is dedicated to training engineers across the entire composites community in composites manufacturing and simulation.

Synthesites provides industrial intelligent process monitoring and control, working in close collaboration with major composites manufacturers in wind energy, aerospace, automotive and other industrial sectors. Its advanced dielectric monitoring systems are based on direct measurement of resistivity (direct current/DC) and accurate temperature of the resin, and have attracted interest from various manufacturing companies (see “NCC and Synthesites work toward intelligent manufacturing for resin infused composites”).

Using Optimold and Optiflow systems, monitoring of resin arrival, temperature, viscosity, gelation, degree of cure and Tg can be recorded during product development and/or production using a range of durable and consumable sensors. Quality control issues such as mixing ratio, resin aging and other features can also be monitored and controlled using this technology. The complete product range — including electronic equipment, sensors and software — is being developed and produced in-house ensuring the necessary high quality and best performance.

Related Content

-

Formable, reusable tooling achieves complex composite parts

CAMX 2024: Hawthorn Composites is displaying an inner and outer tail boom and a multi-chamber composite trailing edge control surface, enabled via its Smart Tooling solution.

-

TPI, University of Texas participate in wind blade cure optimization project

Physics-informed machine learning algorithms will be applied to simulate and optimize composite wind blade curing in an effort to advance smart composites manufacturing in industry.

-

Corebon induction heating

This sidebar to CW’s August 2024 feature article reviews this technology for more efficient composites manufacturing and why it aligns with Koridion active core molding.