Toray develops rapid integrated press molding technology for CFRP mobility components

The process and material innovation simultaneously shapes, molds, thermosets and bonds the core and skin in the same mold, achieving this 10 times faster than conventional autoclave molding setups.

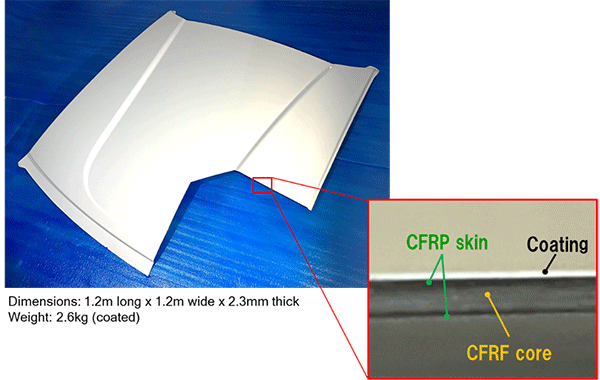

Toray and Takagi Seiko Corp. (Toyama, Japan) molded this large model member with a CFRF core and a CFRP skin. Photo Credit: Toray Industries Inc.

Toray Industries Inc. (Tokyo, Japan) has developed a rapid integrated press molding technology for carbon fiber-reinforced plastic (CFRP) mobility components. This material sandwiches a light, porous short carbon fiber-reinforced foam (CFRF) core (fibers 5-10 millimeters long) with a specially formulated fast cure-type thermoset prepreg.

A combination of process- and material-based innovation, the technology reportedly makes it possible to press mold such components — a car roof, for example — 10 times faster than a conventional autoclave molding setup. Toray obtained findings for this technological advancement under the New Energy and Industrial Technology Development Organization’s (NEDO) Research and Development of Innovative Structural Materials project.

CFRP members typically sandwich urethane foam cores with thermoset prepreg skins. Common applications for these light and rigid structures are large panels for aircraft, automobiles, ships and infrastructure. Some manufacturers have pushed for shorter manufacturing times to optimally bond the core after shaping it to the skin.

Toray confirmed that the skin-core interface did not delaminate and that impact absorption is excellent.

Toray’s new rapid integrated molding technology makes it possible to fabricate large panels in a single shot. Through heat and pressure, the approach simultaneously shapes, thermosets and molds, and bonds the core and skin in the same mold. Ultimately, synchronizing CFRF’s expansion with the prepreg’s curing timing is significantly faster than with conventional processes, Toray reports. The prepreg’s thermoset resin penetrates the porous CFRF to bond the skin and core materials without using adhesives, for a highly reliable bonding structure. Toray’s technology may pave the way for quick production of large CFRP components.

According to the company, CFRF offers significantly better strength, elastic modulus and impact resistance than conventional core materials. Its low specific gravity range of 0.2 to 0.4 can enhance performance and lighten sandwich structures. Toray demonstrated its concept by using a pressing machine to create a large automotive roof panel (1.2 meters long, 1.2 meters wide and 2.3 millimeters thick) in just five minutes. Core thickness before molding was 1.7 millimeters, and 0.8 millimeter after molding. The company assessed rigidity, coatability, sound insulation properties and other practical aspects for automotive production. In vital drop-weight impact tests, Toray confirmed that the skin-core interface did not delaminate and that impact absorption is excellent.

Generally, Toray says it is looking to replace any panel component that its technology can be applied to, taking advantage of the innovation’s ability to create lightweight parts with high rigidity that also excel in impulsivity, sound and heat insulation. Toray says it will keep pursuing R&D to accelerate the application of this technology to electrified vehicle parts, for which lightness and fast production are vital. The company also looks to cultivate such emerging transportation modalities as urban air mobility (UAM) and drones that benefit from functional, lightweight materials.

The technology is still in its development stage, but the company aims to commercialize it by 2030, offering a materials-based technology and a process-based technology as a set.

Related Content

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

.jpg;maxWidth=300;quality=90)