University of Bristol launches composite materials to space for ISS testing

Next-gen carbon fiber materials will be tested under extreme conditions for 12-18 months to determine their viability in space for use in future space bases, interplanetary travel.

Share

Read Next

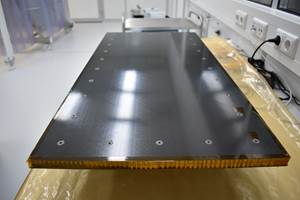

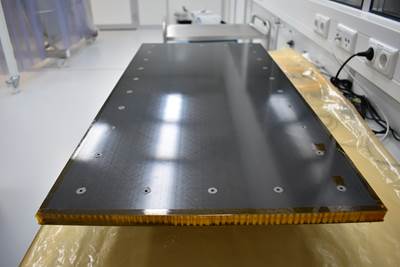

Preparation of one of the Euro Material Ageing’s experiments for launch. The Comat-designed SESAME module holds specimens selected and tested by the ESA, supplied by 15 international research teams with the University of Bristol samples shown in the inset image. Source | Centre National d’Etudes Spatiales/Comat

Early on Nov. 5th, a new generation of carbon fiber-reinforced composite space materials developed by scientists at the University of Bristol (U.K.) was launched to space via a Space X rocket. The rocket is headed to the International Space Station (ISS), where the materials will undergo testing in the extreme conditions of low Earth orbit to determine their ability to be used to build things like future space stations, spacecraft for interplanetary travel or a new ISS.

The composite materials will be placed on the Bartolomeo platform, located on the front of the ISS, where they will orbit Earth up to 9,000 times over the next 12-18 months at speeds of 17,000 miles per hour. They will need to survive temperatures between -150ºC and +120ºC, space debris traveling seven times faster than a bullet, severe electromagnetic radiation, and high vacuum and atomic oxygen, which erodes even the toughest materials.

“Space is the most challenging environment for which to design new materials,” explains Professor Ian Hamerton. He teaches in Polymers and Sustainable Composites department of the University of Bristol’s Bristol Composites Institute. “You’re pitting your materials expertise, skills and ingenuity against extremes of temperature, mechanical stress, radiation, high speed impacts and more. Any one of those might be difficult, and, unfortunately, gaining access to repair them is not an easy option, so the materials we build must survive without maintenance. The opportunity to test our materials in the proving ground of space is priceless and will help our University of Bristol scientists on the ground improve fiber-reinforced materials for next-generation space missions.”

There are four laboratory-made polymers heading to the ISS, each of which has been reinforced with carbon fibers and two contain nanoparticles. All four are the result of University of Bristol research and one is patented.

If the materials cope in the harsh environment, they could be used to create longer-lasting space components, enabling spacecraft to travel further, and spend more time in space.

For related content, read “High glass transition temperature, 100% bio-based thermoset resins for space composites”

Future communities on new planets, for instance, will need protection against galactic cosmic radiation. Dr. Ali Kandemir, senior research associate at the University of Bristol, is one of several Bristol researchers, supported by the UK Space Agency (UKSA), examining the effects of simulated galactic cosmic radiation on the materials in a European Space Agency (ESA) project.

The ISS pictured from the SpaceX Crew Dragon Endeavour during a fly around of the orbiting lab that took place following its undocking from the Harmony module’s space-facing port on Nov. 8, 2021. The red ringed area indicates the likely location of the SESAME module on the Bartolomeo platform. Source | NASA (Dec. 8, 2021), photograph taken by ESA astronaut Thomas Pesquet

“We want materials that are resilient in the space environment and, importantly, materials that can shield humans from that radiation,” says Kandemir. “We also want to make these materials sustainable, so that when they reach the end of their life they can be recycled and used again for the same purpose.”

The launch of the Space X Dragon CRS-2 spacecraft this month is the culmination of 5 years of work for Hamerton and his team. It has included the efforts of early career researchers, postgraduates and several aerospace engineering undergraduates at the University of Bristol, whose final year research projects have been linked to the space materials project.

The support of the University of Bristol-hosted National Composites Centre (NCC, U.K.) was crucial to the scale up of the composite materials. Funding to support the project was supplied by the ESA, the UKSA, Oxford Space Systems and others.

Related Content

On the radar: Reusable launch vehicles, hypersonics make space more accessible

CFRP has become key to targeting efforts in reusing components like rocket stages, as well as the development of reusable hypersonic testbeds and spaceplanes, for increasing space commercialization.

Read MoreNew GTL breakthrough in composite tubing for liquid hydrogen in aircraft and space vehicles

Tests versus stainless steel tubing show 10 times faster chill down, fuel flow in 2 seconds and less boil-off for significantly faster fueling and refueling of LH2-powered space vehicles, aircraft and trucks.

Read MoreNanomaterials optimize performance of space-ready carbon fiber composite panels

A recent ESA project led by Adamant Composites aimed to mature nanomaterial-enhanced CFRP for lighter weight, more thermally and electrically conductive materials for manufacturing satellite structures.

Read MoreNASA launches composite solar sail into space

Sunlight-based propulsion system, supported by carbon fiber-reinforced booms, will undergo weeks-long testing to demonstrate and verify its capabilities.

Read MoreRead Next

University of Bristol, NCC develop novel composite materials to assess performance in space

In-house developed matrices reinforced with carbon fiber will spend six months attached to the ISS to better understand and improve their functionality in extreme space conditions.

Read MoreNanomaterials optimize performance of space-ready carbon fiber composite panels

A recent ESA project led by Adamant Composites aimed to mature nanomaterial-enhanced CFRP for lighter weight, more thermally and electrically conductive materials for manufacturing satellite structures.

Read MoreUltra-thin woven fabric enables 90% resource reduction in satellite solar array manufacturing

Kerberos Engineering uses TeXtreme 0/90 woven fabrics for satellite solar array manufacturing, cutting weight and onboard resources, enhancing structural integrity and streamlining production.

Read More

.jpg;maxWidth=300;quality=90)