AON3D debuts AON M2+ printer to fabricate high performance end-use parts

Printer aimed to exceed aluminum parts using chopped carbon fiber and high-performance polymers (e.g., PEEK, PEKK, ULTEM) via widely available, off-the-shelf filaments.

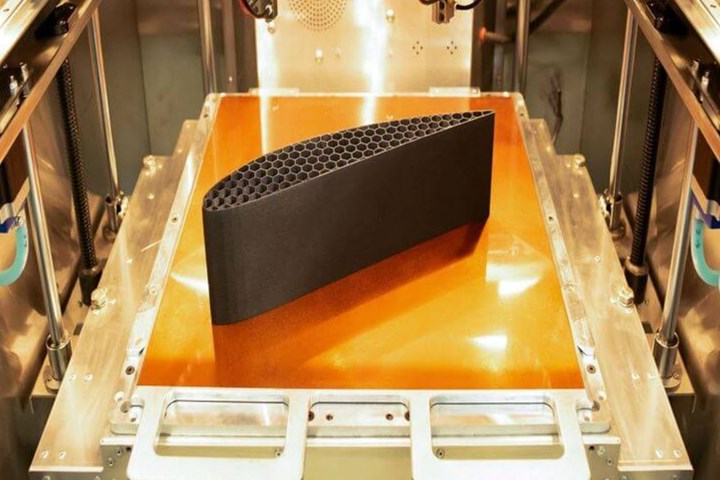

AON-M2 build chamber with chopped carbon fiber/PEEK part made with Solvay KetaSpire AM filament CF10 LS1. Photo Credit: AON3D

AON3D (Montreal, Canada) has announced its new AON M2+ high-temperature industrial 3D printer. Featuring what it claims is the industry’s largest sub-$100,000 actively heated build volume and open material ecosystem, AON3D aims to make full-scale and functional 3D printing accessible to businesses of all sizes. According to AON3D CEO Kevin Han, the AON M2+ was designed by the company’s team of material scientists to take full advantage of current and future economical thermoplastics, carbon fiber composites, and high-performance polymers like PEEK, PEKK and ULTEM.

AON3D explains it manufactures 3D printers to counter the limited build volume, high price and/or lack of material options that exemplify most industrial 3D printer configurations. The AON M2+ reportedly offers high-end features and advanced material capabilities to the mid-market customer without sacrificing hardware quality. Dual independent extruders (500°C), a large, actively heated build chamber (450 x 450 x 640 mm), configurable process parameters and ungated access to thousands of material options are said to provide unlimited end-use printing opportunities. The AON M2+ can print materials that possess a higher strength-to-weight ratio than aluminum, as well as chemical/hydrocarbon resistance, biocompatible/sterilizable properties, thermal resistance above 250°C and more.

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.