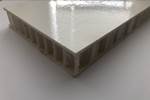

Ultra-light honeycomb blocks are engineered for application versatility

JEC World 2024: Schütz Composites introduces Cormaster, its line of aramid paper-based honeycomb materials suitable in many application fields as panels or parts.

The company is capable of producing honeycomb blocks up to 2,700 × 3,600 mm in a highly automated process. Source (All Images) | Schütz Composites

Schütz Composites (Selters, Germany) is presenting its most recent composite material innovations, including the ultra-light and robust Cormaster honeycomb.

Thanks to its honeycomb shape, the aramid paper-based Cormaster construction material is reported to combine maximum mechanical strength and resistance with very low weight. Cormaster is also resistant to extreme heat and moisture as well as to corrosion from oils, water and paraffin. This modern honeycomb material is suitable for many different applications and is available as sandwich panels, engineered panels, milled or formed parts or curved sandwich panels. Application fields include modern aircraft construction, vehicle construction and motor racing, where they are used for load-bearing structural parts and high-quality interior design. From development to delivery, all process steps at Schütz Composites are certified in accordance with EN ISO 9001 and EN 9100.

At its main site in Selters, the company has expanded its Cormaster production area by more than 6,000 square meters via a new building, significantly enhancing capacity. The new production line includes two fully redundant systems. It is now capable of producing honeycomb blocks up to 2,700 × 3,600 mm in size in a highly automated process.

Schütz has expanded the production area for its Cormaster lightweight construction material by adding an additional production line.

All systems were planned by Schütz’s engineers and largely manufactured in the company’s in-house mechanical and plant engineering department. This approach enables uniform quality standards, a high degree of flexibility and short downtime in the event of potential repairs. Customers also benefit from increased supply security, as the two redundant production lines each have an independent power, gas and thermal oil supply. This means that if one line fails, the redundant line can continue to operate. Another stand-out feature is the modern exhaust air treatment system which reduces CO2 and pollutant emissions.

Schütz Composites cites professional sailor Boris Herrmann and Team Malizia as a key example of how Cormaster can benefit various industries; an official technical partner and supplier, Schütz’s Cormaster honeycomb makes up a large part of the team’s Seaexplorer yacht.

Visit Schütz Composites at Booth E55 in Hall 6.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

.jpg;maxWidth=300;quality=90)