Sperlu prepolymers enable high-performance epoxy resins with up to 80% bio-based content

Spero Renewables has received funding to further scale its pilot production, enabling tunable epoxy resins for composites with Tg of 65-160°C and storage modulus >2,000 megapascals.

Lignin biopolymer is found in all plants, typically comprising 10-25% of their mass. Every year, more than 70 million tons of lignin are burned as a low-value heat source. Spero Renewables aims to create a higher-value supply chain for renewable, bio-based epoxy resins, using its Sperlu process to convert lignin into a variety of biophenols. Photo Credit, all images: Spero Renewables

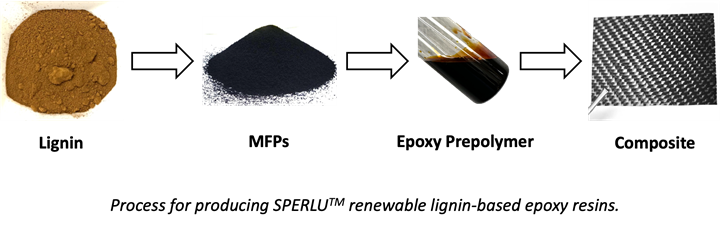

Spero Renewables LLC (Galeta, Calif., U.S.) explains that despite the growing use of epoxy resins, their traditional petroleum-based formulations are not sustainable. This is why it has developed the Sperlu process to produce 100% bio-based epoxy prepolymers from lignin, which is an abundant and low-cost byproduct of papermaking. Lignin’s aromatic chemical structure reportedly provides Sperlu products with thermal and mechanical performance rivaling petroleum-based alternatives.

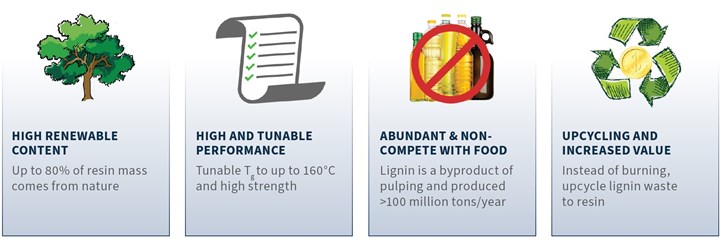

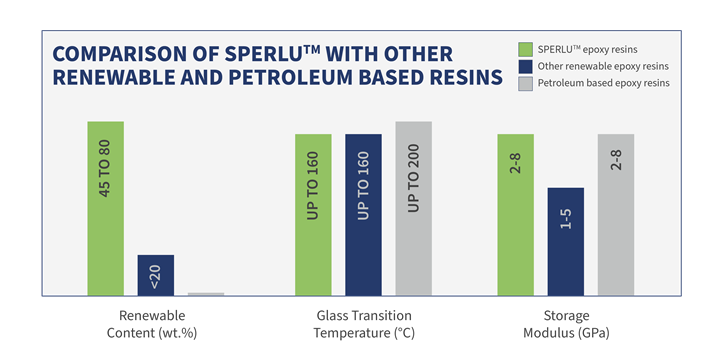

Spero Renewables reports that Sperlu technology overcomes the traditional challenges with lignin — e.g., brittle nature, low solubility, high viscosity and incompatibility with other polymers — and instead delivers high solubility, reactive and compatible epoxy prepolymers that enable tunable strength and the ability to achieve up to 80 wt.% renewable content in epoxy resin (epoxy pre-polymer + hardener) using Sperlu epoxy prepolymers.

This performance results from the aromatic structure of Sperlu prepolymers and their multiple epoxy functions, which provide resins with high strength and stiffness. In comparison, Spero Renewables says that other renewable sources like epoxidized soybean oil or epoxidized cashew nut shell liquid are generally non-aromatic, with lower strength and stiffness. The lower mechanical properties of these competing epoxy prepolymers restricts the total renewable content possible in their resulting epoxy resins to about 20 wt.%.

The Sperlu process uses a novel catalytic lignin depolymerization process to produce multifunctional phenols (MFPs) with a controlled narrow molecular weight distribution. This enables MFPs to directly react with epichlorohydrin in the same style as in the glycidylation of bisphenol A. However, unlike bisphenol A made from the coupling of phenol, or other renewable phenol monomers that need to be modified into multifunctional dimers and/or oligomers, Sperlu MFPs are reportedly multifunctional by nature and no coupling modification is needed.

Sperlu epoxy prepolymers have viscosities comparable to leading epoxy prepolymers, and can be cured with traditional hardeners to achieve epoxy resins with renewable, bio-based content up to 80 wt%. Spero Renewables claims this is much higher than bio-based epoxies with renewable content advertised to be ~20%.

These novel epoxy prepolymers also have high miscibility with bisphenol A diglycidyl ether (DGEBA), allowing formulators to easily tune renewable content and mechanical properties. By mixing Sperlu epoxy with bisphenol A diglycidyl ether, renewable content of 45-80 wt.%, glass transition temperature (Tg) range of 65-160°C and storage modulus of >2,000 MPa can be achieved. The wide range of Tg and high strength make Sperlu epoxy resins suitable for a wide range of applications including automotive, wind turbines, sporting goods and fiber-reinforced composites.

To develop this technology, Spero Renewables has received funding from the U.S. Department of Energy, U.S. Department of Agriculture and the National Science Foundation. It operates a mini-pilot unit at its headquarters near Santa Barbara, Calif., U.S. and plans the construction of a pilot unit capable of processing one ton of biomass per day in preparation for commercial deployment of the technology.

Spero Renewables is seeking commercialization partners and customers. Sperlu epoxy resin samples are available for formulators seeking a direct bio-based replacement for DGEBA.

Related Content

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

.jpg;maxWidth=300;quality=90)