Composites Use in Construction

The role of composites in construction (or infrastructure) is varied, ranging from building of bridges and exterior building cladding, to window linneals and timber reinforcements, to reinforcing concrete structures with composite rebar or fiber-reinforced concrete. However they are used, the lightweighting, design flexibility and durability benefits of composites can help speed construction and improve a building’s sustainability score.

Latest Construction Articles

VIEW ALLBcomp, Temca achieve intricate composite cladding for French school façade

A combination of flax and glass fibers went into the development of 880 openwork, shade-providing panels for an international school in France.

Read MoreGFRP Tech launches South African facility for GFRP rebar production

Said to be the first of its kind in this region, GFRP Tech will manufacture, test and supply flagship EnviraBar and EnviraMesh products to support South Africa’s infrastructure modernization.

Read MoreSwedish parking garage to incorporate decommissioned wind blades

Architect Jonas Lloyd is working with Vattenfall to design the multistory building with a wind blade façade, targeting eco-friendly buildings and creative ways to remove blades from landfills.

Read MoreU.S. grant is awarded for patented SIP composites formwork system

ConTech stay-in-place (SIP) technology, made from recycled composite materials, replaces the use of reinforcing steel in the construction of flat, elevated concrete surfaces.

Read MoreArkema, Sireg Geotech introduce bendable rebar

Sireg Glasspree TP bars, manufactured with Elium thermoplastic resin provides the construction industry with a recyclable, strong and energy-efficient rebar option over steel.

Read MoreDuplicor biocomposites to advance Netherlands housing construction

Holland Composites is developing bio-based, fire-resistant floor elements for the Aer housing concept, achieves milestone in supporting customer sustainability.

Read MoreKnowledge Centers

Closed mold processes offer many advantages over open molding. This knowledge center details the basics of closed mold methods and the products and tools essential to producing a part correctly.

LEARN MORE

In the Automated Composites knowledge center, CGTech brings you vital information about all things automated composites, from the manufacturing processes to the vendors and necessary tools.

LEARN MORELatest Construction News And Updates

Norco GFRP molds meet high-quality cast concrete beam production needs

A project with P&M successfully achieved manufacture of six 20-meter-long architectural beams for an R&D facility with near-seamless surfaces and on a tight production schedule.

WatchPlanefibra embraces a movement aiming to reposition GFRP tiles in Brazil

Recent prejudices threaten to undermine the product’s ESG benefits, which Planefibra is taking steps to negate.

Read MoreEPA selects ACMA, IACMI for $6 million embodied GHG emissions grant

Project supports initiative to reduce construction sector emissions, including developing comprehensive EPDs and PCRs for composite materials and preparing composites manufacturers on their use.

Read MoreDuplicor biocomposite cladding aids redevelopment of ABN AMRO office building in Amsterdam

Chosen for low CO2 footprint, RC value >9, fire resistance, light weight and high strength, Duplicor façade structures are key to two-story extension.

Read MoreRenco USA brings Lego-style composite building system to construction

After more than a decade dedicated to R&D, evaluation and testing, the company has proven its MCFR building system in a Lakewood Village project in Florida.

Read MoreSustainable Infrastructure Systems creates fiber-reinforced post-consumer plastic structural panels

Australian composites manufacturer offers a scalable building solution, already established in a pedestrian bridge application, to tackle unprocessed soft plastics waste.

Read MoreFeatured Posts

Composites reinvent infrastructure

Celebrating National Composites Week, CW shares ways in which composites continue to evolve the way we approach infrastructure projects.

Read MoreFiberglass conduit manufacturer grows into new products, infrastructure applications

Texas-based Champion Fiberglass, a five-time CW Top Shops honoree, expands its success in the fiberglass composite conduit market into new applications and products, looking toward future automation and sustainability initiatives.

Read MoreBio-based, fire-resistant composites become mainstream

Projects use Duplicor prepreg panels with highest Euroclass B fire performance without fire retardants for reduced weight, CO2 footprint in sustainable yet affordable roofs, high-rise façades and modular housing.

WatchComposites end markets: Infrastructure and construction (2024)

Composites are increasingly used in applications like building facades, bridges, utility poles, wastewater treatment pipes, repair solutions and more.

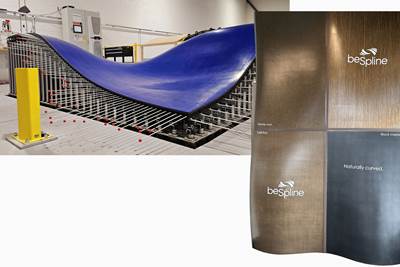

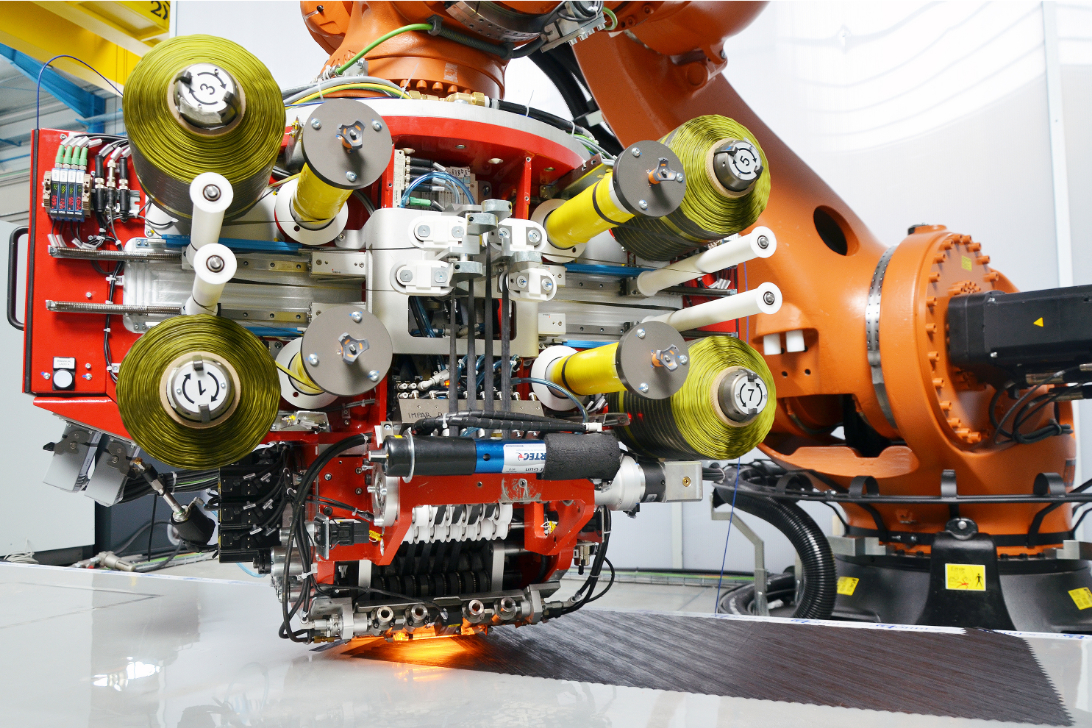

WatchPlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreCirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MoreFAQ: Construction

Why use composites in the construction industry?

A variety of composite materials are used to build structures such as bridges or bridge decking, window components, storage units, exterior cladding and even entire buildings. Composites are also used to reinforce concrete structures, particularly fiber-reinforced polymer (FRP) rebar as an anti-corrosive replacement to steel rebar.

Composites offer lightweighting, design flexibility and durability benefits, all of which can help speed construction and improve a building’s sustainability score.

Are composites used in construction repair?

Composites are increasingly being used to repair structures built with other materials. Target applications include bridge beams, bridge decks, parking garages and pipelines, including underground systems.

Steel-reinforced concrete can be damaged by seismic events and is commonly compromised by temperature-induced contraction and expansion. This results in cracks, which permit moisture invasion, results in corrosion and spalling (expansion) of the steel rebar. That, in turn, aggravates cracking and leads, eventually, to concrete disintegration followed by structural failure. Composites are increasingly used to repair such structures at significantly less cost than new construction, and also to rehabilitate structures that must bear increasing loads beyond the structure’s rated capacity.

Composites can also be used to repair product pipelines, such as natural gas and petroleum pipes at oil refineries and offshore platforms, and to rehabilitate underground storage tanks without the time and expense of excavation.

.jpg;maxWidth=300;quality=90)