Core Materials for Composites

Composite core materials serve as the central structural component in composite structures, providing stability, strength, and support while often contributing to the overall lightweight nature of the final product. These cores, typically made of materials like foam, honeycomb structures, or balsa wood, are sandwiched between layers of composite skins to form a composite panel. Their inherent properties—such as high strength-to-weight ratios, excellent insulation, and impact resistance—make them integral in various industries, including marine, aerospace, and construction, where weight reduction and structural integrity are paramount. The choice of core material plays a crucial role in determining the performance and characteristics of the composite structure.

Latest Core Articles

VIEW ALLVIDEO: Precision fabrication of honeycomb materials

MachineTek showcases its precision fabrication of honeycomb materials at CAMX 2024.

WatchMelker of Sweden accomplishes sea kayak with 100% sustainable composite construction

Built with ampliTex flax fabrics, a solid cork core and plant-based resins, the company’s Värmdö kayak model highlights an environmentally conscious design for paddlers of all levels.

Read MoreComposite SIPs for more affordable, efficient and sustainable buildings

LiteSIP panels and modules enable framing in days, cutting structural labor and total cost by up to 70% and 30%, respectively, while increasing energy efficiency and durability.

Read MoreComposite Kape skateboard delivers durability, pop

Collaborative effort between KraussMaffei and entrepreneur Peter Karacsonyi led to the Vanguard, an in-situ polymerized board comprising fiberglass sandwich composites with a recyclable polyamide.

Read MoreDiab, Brødrene AA celebrate 50 years of composite ferry innovation, sustainability

Partners reflect on the increasing use of Diab foam core and GFRP, CFRP composites in Brødrene AA construction over the years, resulting in lightweight, high-performance and efficient marine craft.

Read MoreHexcel introduces mid-temp Flex-Core HRH-302 honeycomb core

Bismaleimide (BMI) option to serve complex curvatures and thermal management needs of military, commercial and UAM aircraft.

Read MoreKnowledge Centers

CW’s editors are tracking the latest trends and developments in tooling, from the basics to new developments. This collection, presented by Composites One, features four recent CW stories that detail a range of tooling technologies, processes and materials.

LEARN MORE

Closed mold processes offer many advantages over open molding. This knowledge center details the basics of closed mold methods and the products and tools essential to producing a part correctly.

LEARN MORE

Join us for insights into advanced bonding techniques and welding processes for composite materials to ensure durability and structural integrity.

LEARN MORELatest Core News And Updates

Persico Group advances SMART rotomolding cell automation

SMART technology, used for the production of structural and soluble thermoplastic cores, integrates robotics, direct tool heating.

Read MoreReFrame project commits to recyclable CFRP aircraft structure research

German inter-university network HP CFK is investigating recyclable sandwich structures, developing sustainable mobility concepts for applicability in safety-critical aircraft components.

Read MoreTooling foam, core excels in uniformity, high temps and repeated curing

CAMX 2024: General Plastics Manufacturing Co. returns with advancements to its Last-a-Foam tooling board foam and composite core products.

Read MoreRecyclable rigid foam core addresses FST standard needs

CAMX 2024: 3A Composites highlights the fire, smoke and toxicity (FST) properties, sustainability and customization of its Airex rigid foam core product line.

Read MoreMel Composites adds Rohacryl processing to customized core offerings

Addition of machining services for the Evonik structural foam brand expands Mel’s range of foam core delivery.

Read MoreNet-shape machining services available for structural foam core

CAMX 2024: In addition to its distribution of various product materials for the composites industry, Technology Marketing Inc. now assists in machined net-shaped Rohacell structural foam core to customer requirements.

Read MoreFeatured Posts

Guidance for the thermoforming process

A briefing on some of the common foam core material types, forming methods and tooling requirements.

Read MoreAviation-specific battery system uses advanced composites to address electric, hybrid flight

BOLDair’s composite enclosure, compression structures and thermal runaway management enables high-performance electric energy storage.

Read MoreBio-based, fire-resistant composites become mainstream

Projects use Duplicor prepreg panels with highest Euroclass B fire performance without fire retardants for reduced weight, CO2 footprint in sustainable yet affordable roofs, high-rise façades and modular housing.

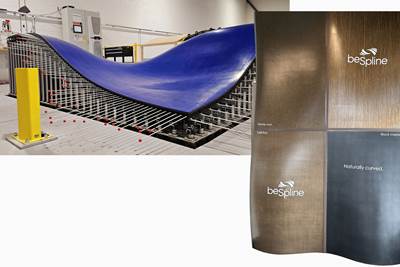

WatchPlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

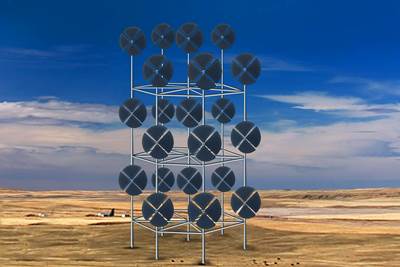

Read MoreDrag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

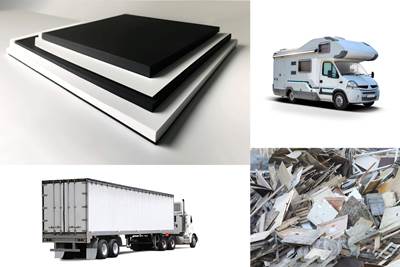

Read MoreA new generation of PP foam core for lightweight truck trailers, RVs

Extruded PP (XPP) foam core offers lightweight, high-performance monomaterial panels that are easily recycled for truck flooring, sidewalls or cabinet/furnitureboards as the transportation industry seeks a replacement for plywood.

Read More

.jpg;maxWidth=300;quality=90)