Narrow Your Design & Tooling Search

Latest Design & Tooling Articles

VIEW ALLRadalytica advances multimodal 3D robotic scanner for composites, future aircraft inspection

Radalytica continues to develop its RadalyX nondestructive testing (NDT) system, merging diverse imaging methodologies for inspection in laboratories to aircraft hangars.

WatchORNL demonstrates lightning strike protection tech for composites

Researchers, led by Vipin Kumar, developed a low-cost, recyclable carbon fiber wind turbine blade tip that showed resilience to high-voltage lightning strikes, with more innovations in store.

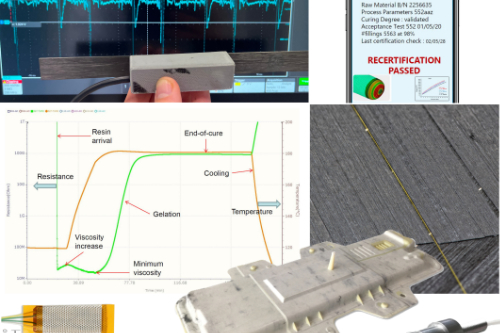

Read MoreThe evolution, transformation of DEA from lab measurements to industrial optimization

Over the years, dielectric analysis (DEA) has evolved from a lab measurement technique to a technology that improves efficiency and quality in composites production on the shop floor.

Read MoreProving thermoplastic composites match carbon fiber/epoxy performance in road bikes

CDCQ, LxSim, Addcomp and Argon 18 collaborate to optimize a carbon fiber/PA6 bike seat post, democratizing AFP and demonstrating materials and process for future designs and production.

Read MoreUniversity of Bristol launches composite materials to space for ISS testing

Next-gen carbon fiber materials will be tested under extreme conditions for 12-18 months to determine their viability in space for use in future space bases, interplanetary travel.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreKnowledge Centers

Discover the types of sensors being used in composites, the physics on which they�re based, their installation, promised benefits and challenges, as well as the potential they offer for even further developments in smart structures.

LEARN MORE

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORE

CompositesWorld’s CW Tech Days: Infrastructure event offers a series of expert presentations on composite materials, processes and applications that should and will be considered for use in the infrastructure and construction markets.

LEARN MORELatest Design & Tooling News And Updates

Solico software suite now includes horizontal tank module

Solico Engineering introduces the module to complete its Amphora calculation tool, made for the design of fiber-reinforced silos and tanks.

Read MoreJuggerbot 3D announces MSU, ORNL as partners for hybrid LFAM composites project

Air Force-funded initiative looks to LFAM thermoset, thermoplastic advancement for fast, inexpensive composite tooling production.

Read MoreBase Materials introduces BE890 epoxy tooling board

Base Materials introduces a high-performance, toughened epoxy tooling board designed for thermoforming and vacuum forming processes, direct-to-part applications and more.

Read MoreAirtech, Ascent Aerospace partner to accelerate AM tooling adoption

A combination of Airtech’s 3D printing materials and Ascent’s production capabilities aim to support increased use of composite additive tooling in spaces like defense and aerospace.

Read MoreAsahi Kasei launches cloud-based CAE platform for FRP deformation prediction

An on-demand mapping tool for anisotropic materials and polymer material fracture prediction model, i-Lupe, aims to help predict impact, crash behaviors.

Read MoreJamco America partners with Airtech for 3DP tool recycling

Aerospace manufacturer joins forces with composite materials company to achieve sustainable manufacturing practices that overcome traditional composite layup tooling.

Read MoreFeatured Posts

Modeling and characterization of crushable composite structures

How the predictive tool “CZone” is applied to simulate the axial crushing response of composites, providing valuable insights into their use for motorsport applications.

Read MoreTesting to support composite bolted joint analysis

An overview of ASTM Standard Guide D8509, and its coupon-level mechanical testing of design properties for analyzing composite bolted joints.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreCorebon induction heating

This sidebar to CW’s August 2024 feature article reviews this technology for more efficient composites manufacturing and why it aligns with Koridion active core molding.

WatchActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

WatchLaser-excited acoustics provide contact-free, nondestructive composites inspection

Xarion’s couplant-free NDT technology uses laser physics and a membrane-free optical microphone, eliminating the requirement for fluid coupling, widening the scope for NDT technology.

Read More

.jpg;maxWidth=300;quality=90)