Filament Winding

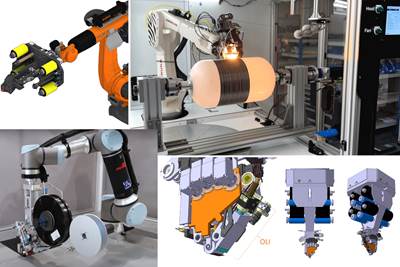

Filament winding is a specialized technique used in composite manufacturing, involving the precise and automated winding of continuous fibers onto a rotating mandrel or mold. This method allows for the creation of strong and seamless structures, optimizing the alignment and orientation of the fibers to meet specific design requirements. Filament winding is employed in producing cylindrical or conical composite parts, such as pipes, pressure vessels, and aerospace components, enabling engineers to tailor the strength, stiffness, and performance characteristics of the final product.

Latest Filament Winding Articles

VIEW ALLPolar Technology announces filament winder installation

Machine addition to a larger dedicated cell will support the company’s higher volume composites manufacturing capabilities and future growth plans.

Read MoreMikrosam robotic filament winding cell to aid Cidetec composites projects

Delivery of the single-spindle robotic setup with an ATP head will advance the R&D organization’s work in CUBIC, GENEX and Carbo4power initiatives targeting sustainable composites development.

Read MoreCompoTech highlights fiber laying technologies to achieve CFRP preform, component versatility

Automated fiber laying (AFL) placement and winding machine technologies enhance OEM capabilities to produce reliable, commercially viable custom composite products.

Read MoreCygnet Texkimp, Bowman Power advance high-tension carbon fiber overwrapping

Together, partners are progressing high-tension e-rotor overwrapping for mass land transport, optimizing accuracy and repeatability at rate.

Read MoreCFRP planing head: 50% less mass, 1.5 times faster rotation

Novel, modular design minimizes weight for high-precision cutting tools with faster production speeds.

Read MoreCompoTech uses integrated loop technology to create high-performance mountain bike

CompoTech features its CDuro Epona mountain bike fitted with custom suspension forks, manufactured using its AFL winding and integrated loop technologies.

Read MoreKnowledge Centers

During CW Tech Days: Thermoplastics for Large Structures, experts explored the materials and processing technologies that are enabling the transition to large-part manufacturing.

LEARN MORELatest Filament Winding News And Updates

Raw materials distributor provides quality fiberglass, resin variety

CAMX 2024: Imate Composites presents a variety of resins, fiberglass and roving products, as well as mats and catalysts.

Read MoreCygnet Texkimp supplies filament winding cell to TWI Materials Integrity Centre

Versatile composites equipment will support the global R&T organization’s research and manufacturing of novel materials and parts for pressure vessels and pipes.

Read MoreDawn Aerospace UAV spaceplane certified for flight, develops smart COPVs

Targeting multiple flights/day, nitrous-based propulsion company also works with Com&Sens and ESA to develop composite-overwrapped pressure vessels with embedded sensors toward qualified 30-liter tanks by 2025.

WatchAutomated towpreg systems provides direct access to wet winding

CAMX 2024: Century Design Inc. highlights its OnDemand towpreg systems, designed to provide differentiation and cost efficiency in-house while maintaining high quality.

Read MoreModular, upgradeable, automated composites manufacturing equipment

CAMX 2024: Mikrosam highlights its filament winding automation, AFP and ATL, modular prepreg slitting and rewinding machine, and towpreg production lines for productivity and reduced costs.

Read MoreFPP technology enables industrial reinforcement of composite tanks

CAMX 2024: Cevotec is introducing the Samba Pro PV-1 FPP system to attendees through a displayed cutout validated with partners and a conference presentation.

Read MoreFeatured Posts

Filament winding increases access to high-performance composite prostheses

Steptics industrializes production of CFRP prostheses, enabling hundreds of parts/day and 50% lower cost.

Read MoreOptimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

WatchCarbon fiber composite pallet revolutionizes freight industry

LOG Point Pallet fuses advanced materials with innovative design and manufacturing to improve supply chains worldwide.

WatchIndustrial equipment manufacturer expands global footprint, reaches into new markets

India-based CW Top Shops honoree EPP Composites reflects on a recently successful vertical filament winding application and new pultruded FRP rebar capabilities, as well as future opportunities.

WatchFiberglass conduit manufacturer grows into new products, infrastructure applications

Texas-based Champion Fiberglass, a five-time CW Top Shops honoree, expands its success in the fiberglass composite conduit market into new applications and products, looking toward future automation and sustainability initiatives.

Read MoreThe next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read More

.jpg;maxWidth=300;quality=90)