Composites Use in Mass Transit

Led by needs to reduce emissions and increase efficiency, there are a variety of opportunities and efforts toward incorporating lightweight composites into more mass transit vehicles like railcars and buses, from vehicle bodies and frames, to doors, tracks, bogies and battery enclosures.

Latest Mass Transit Articles

VIEW ALLNew Flyer selects Hexagon Purus H2 tanks for fifth consecutive year

Type 4 tanks will continue to be supplied for the mass mobility provider’s Xcelsior Charge FC fuel cell electric transit buses.

Read MoreBüfa partners with Končar to develop composite electric rail platform

Končar-Električna to use Büfa fire-retardant composite materials for electric vehicle development.

Read MoreSABIC debuts EN45545 rail-compliant, fiber-reinforced compound

LNP Thermocomp AM DC0041XA51 offers the rail industry a solution that can be used for on-demand printing of large, complex exterior and interior parts in relatively small build numbers.

Read MoreComposite sidewall cover expands options for fire-safe rail components

R&D project by CG Rail explores use of carbon fiber-reinforced thermoplastics and recycled manufacturing scrap to meet fire safety, weight and volume targets.

Read MoreLongtime partner New Flyer selects Hexagon Purus to outfit hydrogen transit bus

Hexagon Purus will continue to supply Type IV hydrogen tanks for the Xcelsior Charge H2 fuel cell electric bus, the tanks of which will be produced out of Hexagon’s new Maryland facility.

Read MoreLIST opens innovation center focusing on sustainable composite materials

The Sustainable Composite Materials and Manufacturing Innovation Centre (SCMM) will be supported by major players in rail, aerospace, automotive and space to transition sustainable composites research to commercialization.

Read MoreKnowledge Centers

This CW Tech Days event will explore the technologies, materials, and strategies that can help composites manufacturers become more sustainable.

LEARN MORELatest Mass Transit News And Updates

Hexagon Purus opens new U.S. facility to manufacture composite hydrogen tanks

CW attends the opening of Westminster, Maryland, site and shares the company’s history, vision and leading role in H2 storage systems.

WatchKimya features Kimya PC-FR 3D filament for the transportation sector

Flame-retardant polycarbonate filament reaches EN45545 certification and meets REACH and RoHS standards for production of parts in railway, automotive, electronics.

Read MoreVoith H2 storage tanks made with in-house towpreg winding

Plug & Drive H2 storage system displayed at IAA Transportation 2022 uses 700-bar tanks for heavy-duty commercial and construction vehicles.

Read MorePlastic Omnium supports development of Safra Hycity hydrogen-powered buses

Passenger transportation retrofit specialist will receive Plastic Omnium’s Type IV high-pressure hydrogen vessels, fuel cell systems, and technical and product launch support.

Read MoreRöchling launches sustainable vacuum forming materials for railway structures

Röchling’s Maywoflamm plus RC and Maywoflamm NFPA RC can be manufactured using up to 70% recycled material, making it possible to increase sustainability in customer applications.

Read MoreBallard Power and Wisdom Motor Co. partner to accelerate adoption of fuel cell commercial vehicles

As part of the collaboration, the companies plan to introduce and demonstrate a double-decker fuel cell bus in Hong Kong this year.

Read MoreFeatured Posts

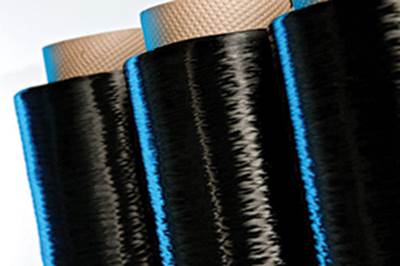

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

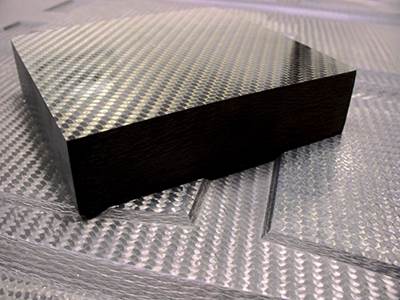

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreRefrigerated railcar floor expands composites horizons

TrinityRail, in an effort to update a 20-year-old design, seizes the opportunity to apply composites in a structural application in its refrigerated railcar. It’s a first for the rail and composites industry.

Read MoreTU Munich gears up for full-scale Hyperloop demonstrator

As a new, university-directed research program, the Technical University of Munich Hyperloop team works to scale up its SpaceX competition-winning pod design.

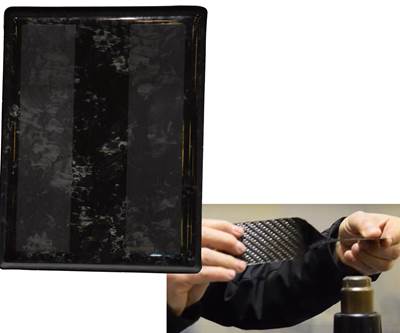

Read MoreThe industrialization of thermoplastic epoxy

Fast-processing composites that are strong yet tough, thermoformable, reformable, recyclable and even FST-compliant save cost in aircraft and rail equipment.

Read MoreFAQ: Mass Transit

How are composites used in buses?

Opportunities for composites have arisen as more all-electric buses have been designed and developed.

Like consumer vehicles, battery enclosures for battery-electric buses are likely to use composites for their light weight, design flexibility and tailorability to meet a range of property requirements.

Several all-composite or partially composite all-electric bus designs have also been developed.

Source: EV battery enclosure inspires material, process innovations

Are composites used in hyperloop designs?

- Some! Several designs have included carbon fiber composite components in the pods and/or tracks for various prototype and competition models over the past several years.

- Source: Into the Hyperloop

.jpg;maxWidth=300;quality=90)