Resin Transfer Molding (RTM)

Resin Transfer Molding (RTM) is a popular manufacturing technique in composite production, involving the infusion of resin into dry fiber reinforcements within a closed mold. This process offers precise control over resin distribution, resulting in high-quality, void-free composite parts. RTM allows for the creation of complex shapes and intricate designs while maintaining consistent mechanical properties.

Latest RTM Articles

VIEW ALLMcClarin Composites partners with ExxonMobil to accelerate high-speed RTM

Multimillion-dollar investment to drive next-gen automated RTM technology will open new applications and markets for composites OEMs.

Read MoreBcomp, Temca achieve intricate composite cladding for French school façade

A combination of flax and glass fibers went into the development of 880 openwork, shade-providing panels for an international school in France.

Read MoreVIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.

WatchAmpliTex-constructed solar-powered ferry hits the Adriatic Sea

The Marservis PROeco is a mass transportation marine vessel using Bcomp natural fiber for interior parts in place of standard materials.

Read MoreKraussMaffei, AIM collaboration achieves HP-RTM carbon fiber wheel rims

KraussMaffei supported, coordinated and delivered compact production equipment tailored to design and process needs for high-quality automotive rims.

Read MoreCorebon induction heating

This sidebar to CW’s August 2024 feature article reviews this technology for more efficient composites manufacturing and why it aligns with Koridion active core molding.

WatchKnowledge Centers

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORELatest RTM News And Updates

Vacuum pack, seals, tubes, fittings enhance RTM process

CAMX 2024: RTM North Ltd. presents Vac Pack, as well as its custom seals, tubes and fittings, to be used in composites RTM.

Read MoreHybrid composite workcell supports thermosets, thermoplastics

CAMX 2024: Radius Engineering showcases its Hybrid Composite Workcell with the versatility to support a range of closed-mold processes monitored by its Insights control system.

Read MoreMolding technologies, integrated automation deliver streamlined production

CAMX 2024: Macrodyne engineers composites and rubber hydraulic presses for domestic and international customers, capable of handling large-scale production demands to more intricate projects.

Read MoreIMDEA introduces digital twin for real-time analysis of composite materials production

Newly designed digital twin by IMDEA and Technical University of Madrid researchers enables manufacturers to see inside composite materials as they are being produced, facilitating early detection of faults.

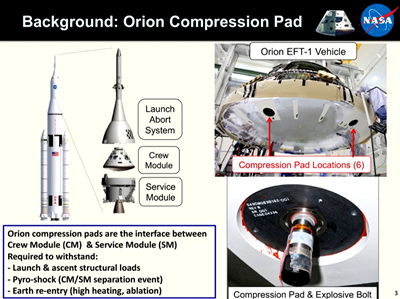

Read MoreBally Ribbons 3DMAT quartz composite is adopted for future NASA space missions

Named the NASA Government Invention of the Year, the 3D orthogonally woven materials supports structural and thermal performance needs for Orion mission and more.

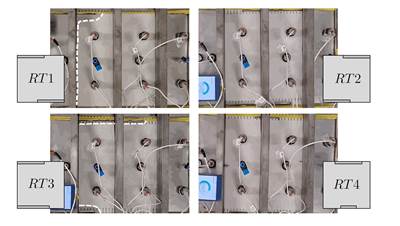

Read MoreLive demonstrations present closed molding advancements

CAMX 2023: The Composites One and Closed Mold Alliance demo zone returns with short but engaging exhibitions featuring vacuum infusion, reusable bag molding, light RTM and other technologies through the show.

Read MoreFeatured Posts

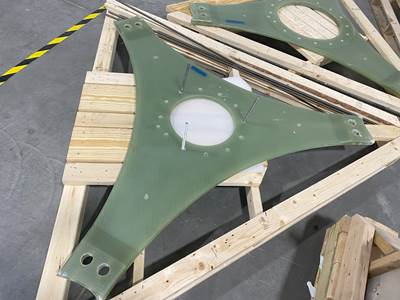

Plant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

Read MoreDesigning an infused, two-piece composite baseball bat

With its Icon BBCOR bat, Rawlings leveraged its experience in braided fabrics and RTM to create an optimized, higher-performance two-piece design.

WatchFrom the CW Archives: The life and death of the BMW i3

A look back at the ambitious and impressive composites production system BMW developed for production of the all-electric i3 EV.

Read MoreBallistic protection panels manufacturer relies on automation for high throughput, efficiency

Maine-based CW Top Shops honoree Compotech Inc. recently doubled its manufacturing space and team to produce modular composite panels for defense applications via light resin transfer molding (LRTM).

Read MoreRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

WatchFrom the CW Archives: Fast-cure epoxies for automotive fabrication

Sara Black’s 2015 report on the development of snap-cure epoxies for automotive manufacturing still resonates today.

Read MoreFAQ: RTM

What is RTM?

Resin Transfer Molding (RTM) is a popular manufacturing technique in composite production, involving the infusion of resin into dry fiber reinforcements within a closed mold.

What does RTM stand for?

Resin Transfer Molding (RTM).

What is Light RTM?

Light Resin Transfer Molding, or Light RTM, is a process by which composite products are manufactured using a closed mold system. The closed mold consists of an “A” side mold (base mold) and a semi-rigid “B” side mold (counter mold) that is sealed to the “A” side mold using vacuum pressure. Resin is drawn into the resulting cavity under vacuum.

The resin infusion may be assisted by a resin injection pump, which will accelerate the infusion process. Once an “A” side mold is cured, the “B” side mold is removed and the part is demolded from the “A” side mold.

Source: Light RTM

.jpg;maxWidth=300;quality=90)