Space

Composites have been used in space since our early steps into the cosmos. Often turned to for their light weight and high strength, these materials have a history of use in spaceflight in such applications as payload fairings, satellite structures and heat shields. ► Explore the technologies, materials and strategies used by composites manufacturers working in the evolving space market at our virtual CW Tech Days: New Space Applications. Learn more and register here!

ESSENTIAL READING

VIEW ALLMaterials & Processes: Composites fibers and resins

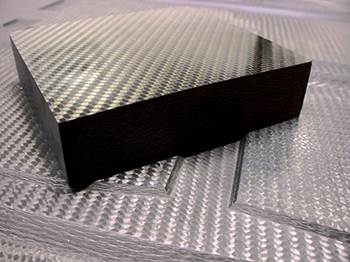

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreMaterials & Processes: Introduction

High strength at low weight remain the winning combination that propels composite materials into new arenas, but other properties are equally important. This article outlines the case for composites and introduces SourceBook's overview of the materials and processes used to make them.

Read MoreKnowledge Centers

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORE

Join us for insights into advanced bonding techniques and welding processes for composite materials to ensure durability and structural integrity.

LEARN MORELatest Space News And Updates

ORNL, Sierra Space create novel C/SiC TPS for reusable space vehicles

CMC tiles will be used on the Sierra Space DC100 Dream Chaser spaceplane carrying critical supplies and science experiments to and from NASA’s ISS.

Read MoreESA collaboration brings Altair software to aerospace, space startups

Access to Altair simulation, AI and data analytics solutions and consulting options to ESA Partnership Initiative for Commercialisation (EPIC) organizations aims to diversify, support aerospace companies.

Read MoreFirefly Aerospace closes oversubscribed $175 million Series D raise

The end-to-end space transportation company looks to its future launch, lunar and on-orbit services and capabilities.

Read MoreIntuitive Machines debuts moon buggy for Artemis program

IM’s Moon RACER is one of three lunar terrain vehicle (LTV) designs being considered by NASA for future operations on the lunar surface.

WatchUniversity of Bristol launches composite materials to space for ISS testing

Next-gen carbon fiber materials will be tested under extreme conditions for 12-18 months to determine their viability in space for use in future space bases, interplanetary travel.

Read MoreComposites support SKA Observatory radio telescope sub-reflectors

Engineering company Eosol and composites developer Compoxi work together to deliver more than 250 4.5-meter composite dishes to construct two cosmos-focused telescopes.

Read MoreFeatured Posts

VIDEO: Rock West's growth in the space sector

Rock West Composites’ chief strategy officer discusses recent surge in space applications on the CAMX 2024 show floor.

WatchPost Cure: CFRP landing leg supports reusable launcher capabilities

MT Aerospace AG, as part of the EU’s Horizon Europe project SALTO, has successfully developed a 7-meter-long carbon fiber-reinforced polymer (CFRP) landing leg demonstrator using advanced automated fiber placement and 3D printing technologies.

Read MoreLow-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreComposites reinvent aerospace, AAM and space

Celebrating National Composites Week, CW shares ways in which composites continue to make a significant impact in aerospace and space market developments.

Read MoreCarbon fiber satellite arm reduces weight, simplifies assembly onto naval vessels

Satcom developer EM Solutions partnered with ACS Australia to replace an aluminum arm design with a 65% lighter, one-piece, corrosion-resistant carbon fiber/epoxy alternative.

WatchAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read More

.jpg;maxWidth=300;quality=90)