Digital Demo: Aerospace Carbon Fiber Infusion

Learn how this process combined with carbon fiber can offer the manufacturer the benefits of increased strength and the ability to make a lighter-weight part.

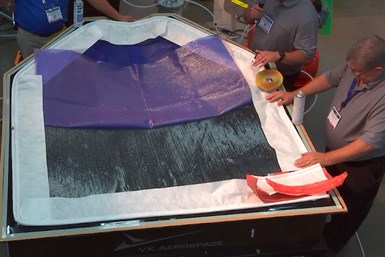

During their annual CAMX demonstration in 2021, Composites One produced a UAV wingskin part using carbon fiber and vacuum infusion. Learn how this process combined with carbon fiber can offer the manufacturer the benefits of increased strength and the ability to make a lighter-weight part.

Composites One also highlights their brand Aerovac, a manufacturer of process materials for vacuum infusion.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.