Fabrics/Preforms for Composites

Composite fabrics or preforms serve as the foundation for creating composite materials, comprising carefully arranged layers of fibers or textiles before they are infused or coated with a matrix material. These fabrics or preforms come in various shapes, weaves, and orientations, allowing engineers to customize the material's properties based on specific application requirements. They play a pivotal role in determining the final characteristics of the composite, influencing factors like strength, flexibility, and weight distribution.

Latest Fabrics/Preforms Articles

VIEW ALLRTM, dry braided fabric enable faster, cost-effective manufacture for hydrokinetic turbine components

Switching from prepreg to RTM led to significant time and cost savings for the manufacture of fiberglass struts and complex carbon fiber composite foils that power ORPC’s RivGen systems.

WatchMonadnock HTAC Veil protects GFRP equipment against corrosion

Binder-free ECTFE-apertured reinforcement maintains a high resistance against chemicals and abrasion at high temperatures, extending performance and integrity of composite systems.

Read MoreChomarat expands range of composite reinforcement options

Rovicore FM core and C-Weave Stabilized woven fabrics are designed to improve the quality and performance of composite materials.

Read MoreQuantum Materials acquires Innegra portfolio of high-performance fibers

The strategic move strengthens Quantum’s position in the development of technical textile solutions for composites.

Read MoreA&P Technology awarded SBIR to further inline inspection

A&P Technology was recently awarded an AFWERX SBIR to expedite the development of inline inspection capabilities for braided composite components for hypersonics and military aircraft.

Read MoreWide fabrics, powder binders for composites

CAMX 2023: Among Saertex’s offerings are 150-inch fabrics, powder binders and quick delivery of its Carbon Basic Line.

Read MoreKnowledge Centers

This CW Tech Days event will explore the technologies, materials, and strategies that can help composites manufacturers become more sustainable.

LEARN MORE

Discover the types of sensors being used in composites, the physics on which they�re based, their installation, promised benefits and challenges, as well as the potential they offer for even further developments in smart structures.

LEARN MORE

Closed mold processes offer many advantages over open molding. This knowledge center details the basics of closed mold methods and the products and tools essential to producing a part correctly.

LEARN MORELatest Fabrics/Preforms News And Updates

Bio-inspired EV underbody panel developed by TPI Composites, Helicoid Industries

Composite underbody panel for battery pack protection, made of stacked multiaxial noncrimp fabric, will serve high-volume commercial and automotive markets.

Read MorePlastics Unlimited completes facility expansion

A 30,000-square-foot expansion to the Preston, Iowa, facility adds assembly and warehouse space, thermoforming and composites manufacturing equipment and robots.

Read MoreReliance Industries enhances polyester textiles with FRX Nofia technology

Polymeric phosphorus-based additive solution brings fire retardance and sustainability to Recron FS fabrics, enabling safe, responsible end-use applications.

Read MoreIndustrial thread company Coats Group opens Huanmantla manufacturing facility

Mexico facility will support the company’s development of high-performance material threads, yarns and fabrics for the automotive and composites industries, among others.

Read MoreTri-Mack introduces thin, lightweight thermoplastic composite enclosures

Durable, low-cost manufacturing support wide range of industrial uses, with option for embedded EMI shielding.

Read MoreCAMX 2022 exhibit preview: Composite Alliance Corp.

Composite part design and fabrication is supported through standard and custom solutions with global tooling, machinery and service supplier Composite Alliance Corp.

Read MoreFeatured Posts

Hybrid process marries continuous, discontinuous composites design

9T Labs and Purdue applied Additive Fusion Technology to engineer a performance- and cost-competitive aircraft bin pin bracket made from compression-molded continuous and discontinuous CFRTP.

Read MoreUnderstanding vacuum bagging layers in production, repair

Recognizing the functions of each layer in a vacuum bag schedule can help users discover what vacuum bag schedules work best for their application.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

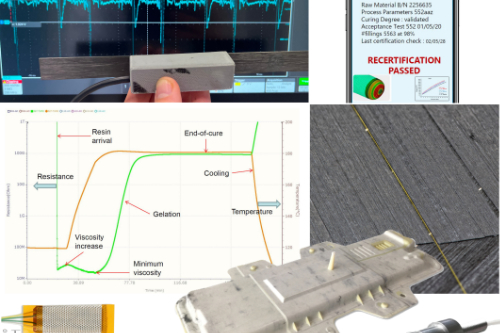

Read MoreReal-time assessment of thermoset composites curing

The combination of material state management (MSM) software and an encapsulated sample rheometer (ESR) enables real-time cure recipe management or cure model development inside the autoclave.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read More