Nanopoxy, Nione jointly develop nanostructured epoxy resin

Epoxies featuring nanometric niobium pentoxide particles promote toughness, UV radiation resistance and other performance gains.

Nanopoxy (Santa Catarina, Brazil), a chemical company specializing in the development and manufacture of special resins, in partnership with Brazilian company Nione, a company developing method to obtain niobium nanoparticles on a large scale, have jointly developed a product that enhances the performance of epoxy resins used in composite applications. The technology was launched during JEC World 2024.

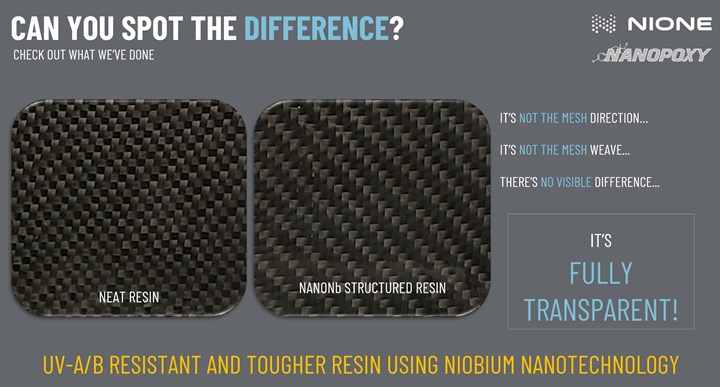

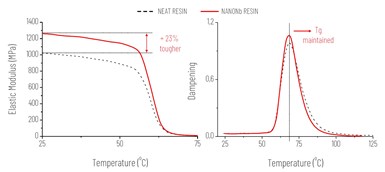

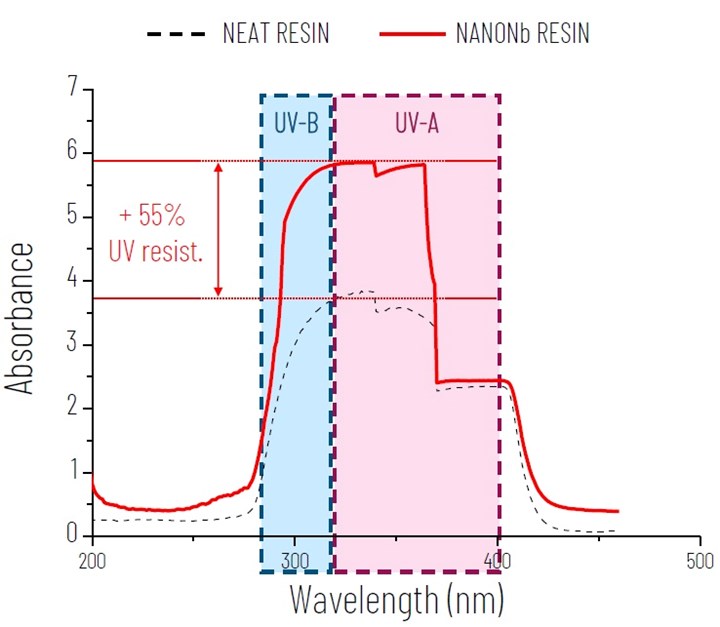

According to Nanopoxy, niobium nanoparticles act as a transforming agent of the polymeric matrix — they modify physicochemical properties and enhance the performance of the resin, promoting gains of about 23% in toughness and 55% in resistance to UV radiation compared to the original resin. In addition, these nanoparticles are said to preserve the natural transparency of the material. These features could enable new opportunities for the use of epoxy resins in composite materials, both partners believe.

“Our partnership with Nione is the result of numerous research and development efforts that we have invested in over the years,” says Bruno Gomes, technical director of Nanopoxy. “[Moreover] Nanopoxy’s presence at JEC World reflects our tireless efforts in creating value through innovation and continuously improving the performance of our products through nanotechnology. This participation provided us with an opportunity to present ourselves on a global platform, expanding our reach and opening doors to new business opportunities.”

Nanopoxy says that it’s the first Brazilian company to develop a bio-based epoxy resin, achieving USDA Biopreferred Certificate in 2019. Then, in 2022, the company launched an epoxy system with graphene nanotubes at Feiplar. “Now, in 2024, we are pioneering globally in the development of a commercially viable epoxy resin with niobium nanotechnology,” adds Gomes.

Nanopoxy maintains a highly qualified team and robust infrastructure for the creation of customized solutions for customers. In addition to its headquarters in Biguaçu, Brazil, Nanopoxy has a strategic presence in the U.S., with an office and warehouse located in Florida.

“We remain committed to innovation and excellence, always looking for new ways to improve and expand our products and services,” concludes Gomes.

Related Content

-

The making of carbon fiber

A look at the process by which precursor becomes carbon fiber through a careful (and mostly proprietary) manipulation of temperature and tension.

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

Price, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.