NASA selects universities for space station research opportunities

Five universities were chosen for grants to design research experiments that will be conducted on the International Space Station. Initiatives such as robotic surgery and SHM using piezoelectric sensors will be realized.

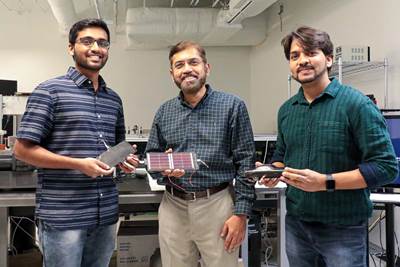

Students from the University of Nebraska team test their robotic surgery tool in a zero-gravity environment. Photo Credit: NASA

Five universities were chosen by NASA (Washington, D.C., U.S.) for grants to provide students with opportunities to design research experiments that will be conducted on the International Space Station (ISS). The selections are part of the agency’s Established Program to Stimulate Competitive Research, or EPSCoR.

Each of the selected universities will receive approximately $100,000 through NASA EPSCoR. They are:

- University of Delaware (Newark)

- University of Idaho (Moscow)

- Montana State University (Bozeman)

- University of Nebraska (Omaha)

- New Mexico State University (Las Cruces)

NASA EPSCoR, based at the agency’s Kennedy Space Center in Florida, provides research opportunities for jurisdictions that have not had the ability to participate equally in aerospace-related research activities. Its support is currently directed toward 25 states and three territories (Puerto Rico, Guam, and the U.S. Virgin Islands).

“Each of these projects has the potential to contribute to critical innovations in human spaceflight on the International Space Station and beyond,” NASA EPSCoR project manager Jeppie Compton says. “We’re very impressed with the ideas put forward in these investigation concepts and look forward to seeing how these technologies perform.”

The new awards will enable students to get hands-on experience preparing payloads bound for space and send their experiments or technology demonstrations to a microgravity environment.

“Getting something on the space station is not trivial in multiple ways,” Alexandre Martin, a previous awardee and professor at the University of Kentucky, notes. “There are a ton of tests you need to do, and there’s a lot of manpower involved. The NASA EPSCoR program exposes students to experiences they wouldn’t normally have.”

Investigations funded by NASA EPSCoR support the agency’s deep space exploration efforts and, ultimately, may assist with developing a long-term presence at the moon in preparation for missions to Mars.

Through the Artemis program, NASA is preparing to send the first woman and first person of color to the moon. Artemis missions will require explorers to be self-sufficient when away from Earth for longer periods of time. An investigation from the University of Idaho will use the space station to study “nonfouling thin film polymer coatings” that could prevent biofilm from forming on water stored in space — a preventative measure crucial for long-duration missions.

A technology demonstration from the University of Nebraska would advance robotic surgery. After years of support and sponsorship from NASA, the university has developed a miniature surgical robot and robotic endoscope camera aimed at enabling an “Operating Room in a Shoebox.” While on the station, the robot is set to demonstrate its ability to cut simulated tissue. The project will determine the amount of force needed to perform an operation, as well as whether microgravity affects precision. If successful, this miniature surgical robot could enable doctors to remotely perform minor surgeries in space.

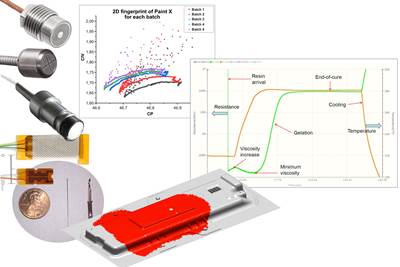

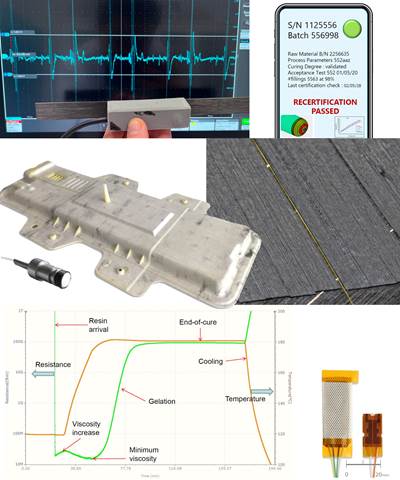

In addition to supporting NASA’s deep-space exploration efforts, investigations funded through EPSCoR contribute to the agency’s low-Earth orbit initiatives, including its Commercial Crew Program. New Mexico State University’s technology demonstration focuses on a structural health monitoring (SHM) system that could be a part of the “black box” recorder aboard new launch vehicles, providing real-time data during stages including pre-flight, in-flight, and post-flight. The system could also play a key role in recertifying launch vehicles for future flights.

According to Dr. Andrei Zagrai, the use of embedded or permanently attached unobtrusive piezoelectric sensors — applicable to both metallic and composite space structures — will be realized in this effort. He notes that these sensors enact ultrasonic guided waves to propagate long distances in the structure and, based on information about propagation characteristics, provide a diagnostic decision regarding structural state. Local high frequency vibration diagnostic is also possible, he notes (for more information about sensors, see “Discover More About Sensors for Composites Processing”).

EPSCoR aims to build lasting research infrastructure in traditionally underfunded jurisdictions by establishing partnerships among NASA research missions, academic institutions, and industry. The program allows NASA to fund investigations critical to its mission while providing outside institutions direct access to space.

Related Content

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreSustainability has come to composites and it's here to stay

It might be tempting to think of sustainability as a buzzword, but there are structural changes taking place in the composites industry that signal its permanence.

Read MoreComposites UK launches best practice guide for composites tooling

“Mould Tooling for Fibre-Reinforced Polymer Composites” is latest in Composites UK’s series of good practice guides, available online for free.

Read MoreAutomated filament winding system increases throughput, reduces manual labor for pressurized well tank production

For its new line of composite well water tanks, Amtrol worked with Roth Composite Machinery on an automated process for faster, more easily tracked production.

Read MoreRead Next

Sensors: Data for next-gen composites manufacturing

In the quest for sustainability, sensors are reducing cycle times, energy use and waste, automating closed-loop process control and increasing knowledge to open new possibilities for intelligent manufacturing and structures.

Read MoreDiscover More About Sensors for Composites Processing

Throughout 2020 and 2021, CW has reported on sensors that can be used to process composites, as well as projects that demonstrate their installation and capabilities. This microsite collates CW’s reporting on sensors to provide, in one place, information about the types of sensors being used in composites.

Read MoreUCF, NASA researchers design charged composite “power suits” for electric vehicles and spacecraft

The lightweight, supercapacitor-battery hybrid composite material has the potential to store energy to supplement the power typically stored in batteries.

Read More