NASA's Lucy spacecraft, built by Lockheed Martin, begins journey to Jupiter's Trojan asteroids

Launched for its 12-year journey in space, the Lucy aircraft is decked out with advanced scientific instruments, 170 square feet of composite structures and several 3D-printed parts.

Photo Credit, all images: Lockheed Martin

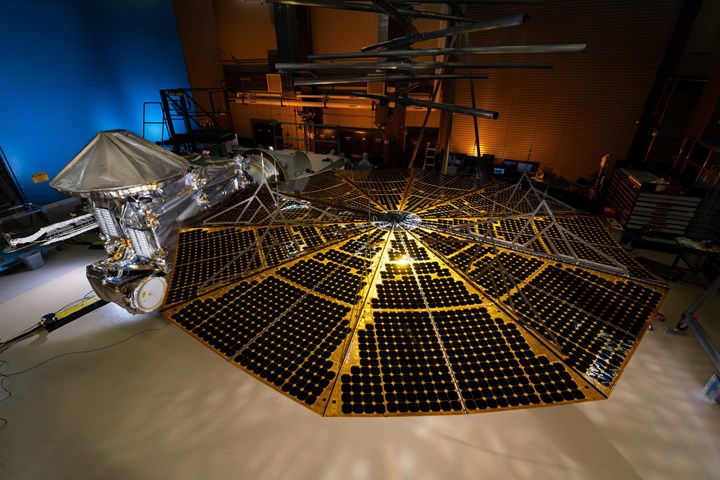

Lucy, a composites-intensive spacecraft designed, built and tested in Lockheed Martin’s (Bethesda, Md., U.S.) Littleton, Colo., facility, was successfully launched by NASA (Washington, D.C., U.S.) from Cape Canaveral’s Space Force Station in Florida on Oct. 16 at 5.34 a.m. ET. The spacecraft is expected to unlock new knowledge about Jupiter’s Trojan asteroids, which are believed to be some of the oldest remnants from the formation of the solar system 4.5 billion years ago.

“Seeing Lucy start her journey reinforces the strength of the 500 team members from NASA, Lockheed Martin the Southwest Research Institute and many other teams who worked together to bring this mission to life,” says Rich Lipe, Lockheed Martin Lucy program manager. “It’s a tale centered on flexibility, collaboration and ingenuity, which is fitting for the voyage that lies ahead for this advanced spacecraft.”

Taking its name from the fossilized human ancestor that revealed insight into humanity’s evolution, Lucy is expected to be the farthest solar-powered mission from the sun and will visit a record-breaking number of asteroids, all in the name of studying them for clues about our own origins. The spacecraft’s four-billion-mile odyssey through the solar system will last 12 years and fly by eight objects: one Main Belt asteroid and seven Trojan asteroids that lead and trail Jupiter in its orbit.

With such a long journey through space, Lucy’s engineers designed the spacecraft to be ready for anything. Lucy draws on heritage design elements from previous Lockheed Martin-built missions like OSIRIS-REx and MAVEN.

Key features of the Lucy spacecraft include:

- Some 430 components, brought together by more than two miles of wire, 170 square feet of composite structure and more than 12,800 electrical connections. Composite materials are primarily from Toray Advanced Composites (TAC, Morgan Hill, Calif., U.S.), including the use of the company’s M55J carbon fiber material with a EX-1515 cyanate ester prepreg resin system for all of the sandwich panels and the truss elements.

- Three primary instruments to study the geology, composition and structure of the Trojan asteroids.

- Two 24-foot diameter solar arrays built by Northrop Grumman (Falls Church, Virg., U.S.), spanning more than a four-story building when unfurled.

- A robust thermal design that protects Lucy from extreme space temperatures ranging from -250ºF to +300ºF.

- Autonomous software that enables Lucy to track asteroid targets as it flies by at an average speed of 15,000 miles per hour.

- Advanced production parts like 3D-printed brackets and harness clamps, made from three different materials.

The team also made use of the latest collaborative tools and digital engineering techniques on Lucy, including automated testing, digital test review capability and remote collaboration. These tactics helped the team continue production without missing a shift throughout the pandemic.

Streak shot of Lucy’s successful launch on Oct. 16.

Lockheed Martin Space designed, built, tested and operated Lucy out of its Littleton, Colo., facility. NASA’s Goddard Space Flight Center in Greenbelt, Md., provides overall mission management, systems engineering and safety and mission assurance. The Boulder, Colo., branch of Southwest Research Institute (San Antonio, Texas, U.S.) is the principal investigator institution. Instruments were contributed by NASA Goddard, Arizona State University and Johns Hopkins Applied Physics Laboratory. Marshall Space Flight Center in Huntsville, Ala., manages the Discovery Program for the agency’s Science Mission Directorate in Washington, D.C.

Related Content

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreRead Next

AON3D, Astrobotic to send 3D-printed parts to the moon

The Peregrine Lander will carry thermoplastic parts printed via AON3D’s high-temperature industrial 3D printer that meet demanding space requirements and cut the vehicle’s weight by half.

Read MoreA new space race

In the past year, new technologies have increasingly aided the potential of space tourism. But the question remains: Does this accessibility reflect a viable business and will it and the associated use of composites get us closer to successfully returning to the moon and beyond?

Read MoreAirbus delivers second composites-intensive European Service Module for NASA’s Orion spacecraft

The ESM-2 module, comprising carbon fiber sheets and 19-meter CFRP solar array wings, will provide propulsion, power and thermal control, as well as oxygen and water for astronauts on the Artemis II mission.

Read More