Machinery, systems manufacturer highlights 3D printing, thermoplastics processing

CAMX 2023: KraussMaffei is featuring a variety of technologies, including Fiberform, ColorForm, RTM, extruder-based 3D printing and more.

German company KraussMaffei (Munich, Germany and Hebron, Ky., U.S.) is presenting several technologies — resin transfer molding (RTM), FiberForm, ColorForm, 3D printing and aviation-related activities — developed by its Lightweight Competence Centre.

For RTM, KraussMaffei references experience with more than 80 supplied RTM plants including presses, dosing and mixing equipment. Most of these machines have been supplied for automotive applications. Since 2013, KraussMaffei has been active in the technology transfer of high-pressure resin transfer molding (HP-RTM) to aviation applications, along with the development of in-situ process monitoring. Moreover, through several R&D projects, and together with partners along the process chain, KraussMaffei is becoming able to provide answers to aerospace requirements that are specific for manufacturing technologies in the qualification process.

FiberForm, another technology from KraussMaffei, combines the thermoforming of organosheets and injection molding into one process, resulting in fiber-reinforced thermoplastic components that are particularly lightweight yet feature a high level of strength and structural rigidity. FiberForm parts are primarily used in the automotive and aviation sector and the use of a thermoplastic matrix system provide welding and recycling advantages. The injection molding process enables the integration of functional elements into the part, such as window guidings into door carriers.

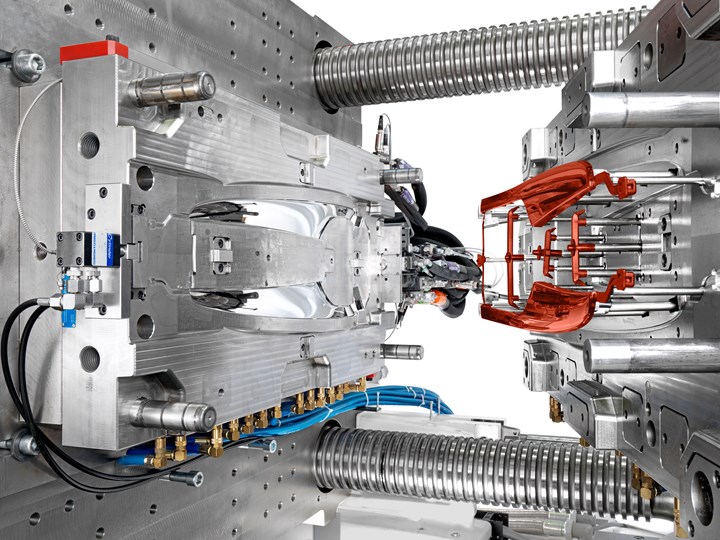

KraussMaffei claims that it is the only company in the industry building reaction processing, injection molding and extrusion machinery. This has enabled it to develop technologies like ColorForm. ColorForm is based on the principle of multicomponent injection molding, but the process does not use a second thermoplastic injection unit once the basic thermoplastic body has been injection molded. Instead, the second stage involves flow-coating the substrate of the basic body with polyurethane (PUR) or polyurea (PUA). A leather-like feel, a particular look or high scratch resistance can be manufactured in just one process step that is both reproducible and cost-effective.

In the additive manufacturing field, KraussMaffei have made use of its extrusion know-how, presenting the company’s new large-scale, extruder-based 3D printer powerPrint. A variety of thermoplastic materials can be used to create parts up to 2 × 2.5 × 2 m. High-performance fiber-reinforced materials and individual compounds are also possible. On the heated printing table parts like molds, packaging or even customized furniture can be produced.

Related Content

-

Download today's CAMX 2022 Show Daily: Tuesday, Oct. 18

Download today’s news reported live by CW on the CAMX show floor in Anaheim, California. Headlines cover this morning’s keynote, Michael Steep, Good Day, CAMX, ACE/CAMX award finalists and more.

-

CAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

-

CAMX 2022 exhibit preview compilation, Part 1

CompositesWorld presents some of the 120 exhibitor previews received highlighting key technologies, services and trends at this year’s CAMX.