R&D projects, additively functionalized part demonstrate composites innovation

JEC World 2024: The DLR is presenting the EmpowerAX multi-curved shell demo part as a JEC Innovation Award winning innovation, in addition to results from other projects involving hydrogen tanks, wind and more.

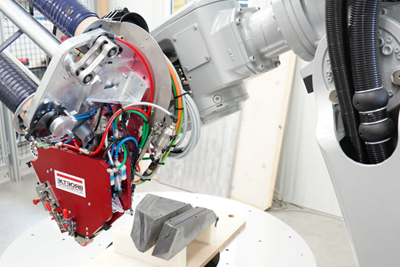

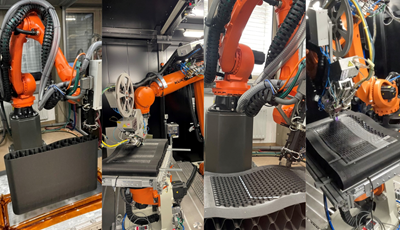

DLR – Institute of Lightweight Systems’ (Braunschweig, Germany) award-winning EmpowerAX demo part, an additively functionalized, multi-curved thermoset shell, showcases the concept of additive functionalization and its industrially available process chain.

The EmpowerAX demo part is a collaborative project between the DLR and twelve industrial players — from design and simulation experts to CAD-CAM specialists to printing and material suppliers — demonstrating the capability of overprinting a multi-curved thermoset shell with high-performance, short- and continuous fiber-reinforced thermoplastic material. This approach combines cost-efficient composites manufacturing with the high agility and design freedom of additive manufacturing (AM).

This year, the EmpowerAX demo part won a JEC Innovation Award in the “Aerospace Process” category and will be exhibited by EmpowerAX partner Hans Weber Maschinenfabrik/Weber Additive at Booth P138 in Hall 5 (learn more about this project in the video below).

The DLR Institute of Lightweight Systems and the DLR Institute of Structures and Design (Stuttgart/Augsburg, Germany) is also presenting results from other R&D projects including AddCompS, UpWing, EnerWing, SuCoHS and the next-generation tank (NGT).

The institute’s strategic field AddcompS aims to increase manufacturing efficiency by combining conventional composites manufacturing processes with AM — additive extrusion in particular. The DLR is presenting a new development in this field, namely a new life for fibers derived from production waste or otherwise reprocessed (nonwoven, etc.) via co-extrusion to develop high-performance, reinforced semi-finished products. The DLR’s state-of-the-art processing facilities produce these filaments with minimal tensile forces that limit process downtime. The organization also demonstrates the wide range of possible applications for the concept of additive functionalization.

Through the Clean Aviation UpWing project, the DLR is investigating double-double (DD) composite laminates at full scale. This family of laminates provide key tapering opportunities for composites engineers in aerospace, DLR notes, which can’t be realized with today’s conventional laminates. Thickness tapering enables precisely designing panel surface shapes in flexural load conditions, which is particularly valuable when tight aerodynamic tolerances need to be met. In UpWing, a “DD flex panel” was developed to experimentally test the predicted surface shapes.

Within the SuCoHS project, DLR and partners investigated high-performance composite structures demanding thermomechanical resistance. The SuCoHS panel is a test structure representative of an aircraft tail cone component which exhibits severe thermal loads generated by the APU. The structure is designed with enhanced thermomechanical resistance. Structural testing proved performance at elevated temperatures above 200°C and paves the way for further exploitation of composite material potential.

Another project, EnerWing, uses Airborne Wind Energy Systems to generate electricity. The technology is said to generate energy at higher and windier altitudes. The aerodynamically optimized wing developed in EnerWing is now ready for long-term testing. The structural test wing is being exhibited at the DLR booth.

Lastly, in a stepwise approach, tank concepts with 400-, 1,700- and 3,000-mm diameters are currently being investigated from a manufacturing and testing point of view. It is equipped with sensors that monitor first the manufacturing process and then the condition of the tank throughout its life cycle. For weight-sensitive applications like aerospace, the development is clearly focusing on liquid hydrogen tanks produced with AFP. The larger tanks are targeting non-land-based transportation systems.

Visit the DLR at Booth T90 in Hall 6.

Related Content

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreMikrosam, H2Storage collaborate on 300+-liter Type IV hydrogen tanks

Automated filament winding cell achieving wind speeds of 6 meters/second improves production performance, shortens curing cycle for serial production of 700-bar Type IV tanks.

Read MoreHexagon Purus opens new U.S. facility to manufacture composite hydrogen tanks

CW attends the opening of Westminster, Maryland, site and shares the company’s history, vision and leading role in H2 storage systems.

Read MoreHexagon Purus Westminster: Experience, growth, new developments in hydrogen storage

Hexagon Purus scales production of Type 4 composite tanks, discusses growth, recyclability, sensors and carbon fiber supply and sustainability.

Read MoreRead Next

DLR develops safe, flexible workspaces for robot-assisted manual draping

The EU project Drapebot works on new ways of collaborating with industrial robots for manual CFRP preforming for large aircraft structural parts.

Read MoreBroetje-Automation demonstrates rCF placement via AFP

Through the ScrapSeRO project, the system integrator and machine builder successfully processed recycled composites, in addition to more traditional materials, via its highly flexible Staxx One system.

Read MoreDLR project demonstrates hybrid AM process for composites

Latest DLR development in 3D printing combines additive extrusion technologies and AFP to present a new approach for manufacturing complex thermoplastic composite structures.

Read More

.jpg;maxWidth=300;quality=90)