787 integrates new composite wing deicing system

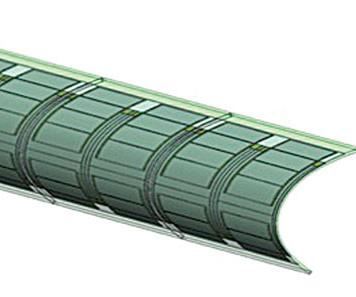

The composite wing leading edge on Boeing’s Dreamliner features an integrated heating element that incorporates a sprayed metal conductive layer within the laminate stack.

One of the most critical requirements of aerodynamic lift in aircraft flight is a smooth wing surface, and one of the easiest ways to make a wing surface irregular is to add ice to it — a layer of ice even 1-mm/0.04-inch thick can be enough to destabilize an in-flight airplane. For large commercial aircraft that fly at high altitudes in subzero temperatures, keeping ice in check is a fundamental wing leading edge function.

Wing ice management falls into two broad categories: anti-icing (ice prevention) and deicing (ice elimination or mitigation). Most technology focuses on deicing, operating on the assumption that some ice is going to form on a wing, and works to get it off before it becomes problematic. Almost all deicing technologies rely on a substance (usually a sprayable chemical applied prior to takeoff) or an onboard mechanism that destabilizes the ice, thus allowing the slipstream to dislodge it and remove it from the wing.

In the mechanical systems category, commercial aircraft have most recently been equipped with deicing systems that bleed hot air from the engines through a series of ducts, which circulate it under the wing surface on which ice builds up. One promising technology that’s been considered over the years involves the integration of conductive elements under the leading edge surface to directly heat the wingskins and, thereby, keep ice from accumulating. The design challenge for such a system is to develop a heating coil, foil or element that can provide even, consistent heat distribution and is robust enough to carry an unbroken electrical current in severe operating conditions. Further, an integrated heating system must be easy to replace in case of damage or malfunction. Until now, their inability to meet all these requirements have kept previously proposed integrated heating systems out of commercial aircraft wings.

A sprayable conductive layer

GKN Aerospace (Redditch, U.K.) has been engaged in heating-element research for several years and very recently has developed a composites-based solution that is poised to see commercial use for the first time on the wing leading edge of the forthcoming 787 Dreamliner from The Boeing Co. (Seattle, Wash.). In addition, GKN’s technology also is seeing military use on the engine intake for the V-22 Osprey tiltrotor military personnel aircraft and the inlet for the F135 Pratt & Whitney engine on the F-35 Lightning II Joint Strike Fighter.

GKN’s solution represents a relatively radical departure from most previously tried heating-element deicing systems and holds promise for extension into a variety of related applications.

Frank Bamford, senior VP, business development and structures for GKN, has been working on the company’s deicing technology for several years and explains that the GKN technology is notable because it uses a spray mat metal deposition technology — liquid metal sprayed on a fiber fabric — to provide electrical conductivity for a heated wing leading edge. More importantly, GKN’s solution does not technically provide a heating element; the metal instead acts as a conductor and an electrothermal element that transfers heat to the wingskin. Says Bamford, “This is a spray-on metal technology that can be embedded in a metal or composite surface, but we have refined it for the 787 to embed in a carbon fiber composite structure.”

Heater mat construction

For the 787, V-22 and F-35, GKN embeds its spray-on metal material in what it calls a heater mat. The heater mat is a cured, multi-ply composite structure of carbon fiber, glass fiber and the spray-on metal, shaped in or on a tool to match the surface for which it is providing deicing capability. There are no constraints on the shape or size of a heater mat except for the available power budget on the aircraft. On the 787, GKN manufactures eight heater mats for the aircraft, which form the leading edges on the eight wing slats (the repositionable portions of the wing leading edge; see first illustration, at right), four per wing. Each mat, and therefore each slat, is considered to be a heating zone and is segmented to provide four to eight heating areas per slat (see second illustration, at right). Finished heater mats are delivered by GKN to Spirit AeroSystems (Wichita, Kan.), where they are attached to the slats via predrilled holes in the mat.

A heater mat, no matter the application, is manufactured basically the same way, with variation provided by the shape of the structure to which it’s to be attached and the strength/structural requirements of the application. For the 787 leading edge, Bamford says mats are layed up on male aluminum tooling, which GKN says offers the durability re-quired for the anticipated production volumes. The tools and subsequent parts are essentially flat on the axis of their length, but must conform exactly to the Boeing-specified aero-dynamic curvature of the wing leading edge across their widths.

Layup begins with a ply stack of carbon fiber/epoxy prepreg, either woven or unidirectional. On the 787 heater mat, the prepreg is woven. The initial stack comprises about 15 plies, cut and kitted with an almost fully automated cutting system. The number of prepreg layers varies, depending on the application.

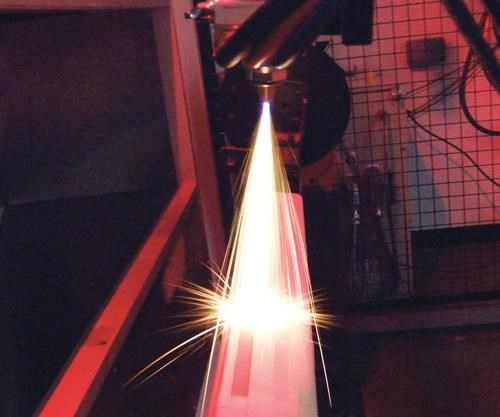

On top of the carbon fiber stack, GKN places a layer of dry woven glass fiber fabric. This is necessary to provide an insulative layer between the carbon fiber and the metal spray to prevent galvanic corrosion. The metal, the composition of which is proprietary to GKN, is applied broadly to the glass fiber fabric with a hand sprayer and allowed to cool and solidify. The thickness of the metal layer can be varied for the application; a thicker layer, says Bamford, provides less electrical resistance, while a thinner layer provides more. The spray process is strictly manual right now, but Bamford says GKN is looking to migrate to an automated system. The surface that receives the spray metal is masked to create the proprietary element pattern. Then wiring that will connect each sprayed metal element to the onboard power system is soldered to the metal.

On top of the solidified metal layer, GKN then places another layer of dry woven glass fiber fabric, again to provide galvanic insulation between the metal and the carbon fiber. On top of this are placed 15 or so additional layers of woven carbon fiber/epoxy prepreg. When the layup is complete, the entire heater mat stack is covered with a caul plate that forms the leading edge’s smooth aerodynamic exterior surface, then vacuum bagged and autoclave-cured. Following cure, the final part shape and aircraft attachment holes are CNC-machined, the latter with the help of GKN proprietary drills that lend themselves to cutting through a glass/carbon hybrid composite. Bamford reports that GKN is avidly pursuing an out-of-autoclave prepreg for use in future applications; he is optimistic that an autoclave-free process will be developed soon.

Molded in one piece, each heater mat is easily attached to its respective 787 slat and easily replaced in case of damage or malfunction. Bamford notes that the heater mat looks like any composite part except for the power cabling leading away from it.

On the 787, the heater mats provide deicing service only, at a temperature range of 45°F to 70°F (7.2°C to 21.1°C). Power consumption for this service is 45 to 75 kW. Anti-icing capability requires a power supply of 150 to 200 kW on an aircraft the size of a 787. “We’re trying to keep power consumption to a minimum on the Dreamliner,” says Bamford. “We only need enough power to break the adhesion of ice to the structure to shed ice from the wing.”

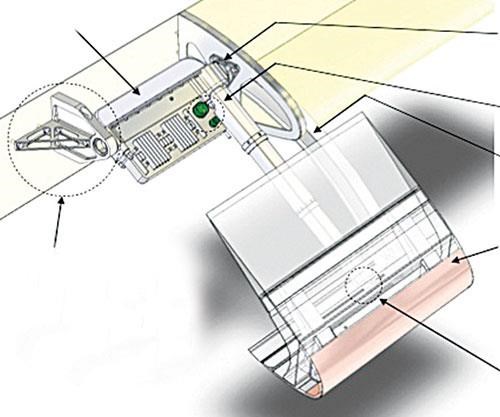

Power control for the heater mat is provided by a system developed by Ultra Electronics (Greenford, U.K.). The controller, one per slat, is located within the equipment bay and attaches to the heater mat via the Transition Wire Bundle, a specially designed telescoping wiring system that extends and retracts with the slats as they open and close during flight.

Design/build flexibility

To accommodate different application complexities, GKN can and will use honeycomb core to provide stiffness; it also will change the shape and thickness of the carbon fiber ply stacks above and below the metallic layer to add or subtract strength as necessary. For example, the heater mats provided for the V-22 and F-35 engine intakes require a very different shape configuration than that used on the 787 slats.

Additionally, GKN can, if warranted by the application, place the metallic layer anywhere else within the ply stack, including as the exterior layer, exposed directly to the airstream or as the inside layer. In any case, the uniformity of the metal application, combined with its easy conformity to shape, provides an even distribution of heat throughout the mat that rivals the performance of foil- or wire-based systems, reports GKN. Given that GKN has recently purchased the Airbus wing manufacturing facility in Filton, U.K., which is expected to produce wingsets for the forthcoming Airbus A350 XWB, it’s likely this deicing technology will see application on that aircraft as well.

GKN’s success with the sprayed metal technology doesn’t begin and end with ice mitigation. It’s got the company thinking more critically about other applications. “The GKN spray-metal system could do a lot of the work done by power distribution systems,” says Bamford. By changing the type of signal transmitted by the mat, GKN thinks there is great potential for it in sensor-based structural health monitoring applications to detect stresses, loads, cracks, breaks and other material flaws that might otherwise be difficult or impossible to detect.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreHighly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)