Check Out the Competition: Visit the Awards Pavilion at CAMX

If you're headed to CAMX 2014, Oct. 13-16 in Orlando, Fla., be sure to check out the entries in the Awards for Composites Excellence (ACE) and the CAMX Awards — some of which are previewed here.

Take a sneak peak at some of the award entries that will be on display at CAMX 2014. Featuring two awards programs with more than 80 submissions, the Awards Pavilion at CAMX is sure give attendees a first-hand, up-close look at innovators and innovations that are shaping markets, inspiring solutions and shifting composites industry expectations.

The CAMX Award will make its debut this year, recognizing innovation that will significantly impact composites and advanced materials in the marketplace. In 2014, CAMX 2014 is celebrating visionary concepts and products by awarding two entries that show strength through collaboration and unsurpassed innovation.

ACMA, host to the long-standing Awards for Composites Excellence (ACE), is bringing this highly coveted awards program to CAMX. The six ACE awards recognize outstanding achievements in design, manufacturing and market growth.

Companies that win these awards join an elite group of leaders and visionaries within the composites and advanced materials community. Following is a look at some of the companies that are displaying their innovations at CAMX 2014.

Some entries appear in both competitions and are so marked. Winners will be announced at CAMX. Visit www.theCAMX.org for more information about the show and awards.

Blackbird Ukulele Made of Lingrove's Ekoa Flax/Bioresin Prepreg

ACE – Design Category: Innovation in Green Composites Design Award

Submitted by: Blackbird Guitars

Blackbird Clara is a concert-sized composite ukulele with the previously unobtainable combination of world-class sound, vintage look in a wood-free, worry-free and sustainable package. The high-performance hollow-neck, uni-body construction is free of the durability and weather stability issues suffered by wooden instruments, making Clara the perfect take-everywhere instrument. Clara is made of Ekoa, a lighter-than-carbon, renewable flax/bioresin prepreg developed by Blackbird and Lingrove. This new biobased solution is tuned to sound like a Stradivarius, but unusually strong and thus offering a wonderful alternative to cutting down old-growth trees.

Lingrove's Ekoa prepregs are made from renewable flax fibers and naturally derived resins. Clara's Ekoa construction has several ecological benefits that help reduce environmental footprint. Blackbird has dedicated several years of research and development to incorporating resonant eco-materials into advanced composite construction. The flax fabric is CO2 negative, requires no irrigation and very low energy to process, while the bioresin is derived in large part from industrial waste. Ekoa is more stable and resilient than wood, helping Clara live many generations and many times longer than a typical ukulele. Ekoa is a replacement material for the old-growth wood used by instrument manufacturers currently, which protects the rainforests — the biggest CO2 absorbers. Blackbird designed production around San Francisco manufacturing constraints, so each Clara requires minimal finishing. Consistency and material stability help improve manufacturing time and quality considerably. Machining Ekoa do not affect air quality, thus enabling a safe work environment.

Collapsible Aerodynamic Device for the Rear of a Semi Trailer

ACE – Design Category: Innovation in Green Composites Design Award

Submitted by: Ridge Corp.

This aerodynamic device provides fuel savings to the Class 8 truck and trailer market. The product saves nearly 5 percent in fuel consumption, and more 10 percent when coupled with other aerodynamic fairings. It is manufactured using a unique thermoforming process that shapes integral hinges and stiffening flanges into flat sheet, laminated, continuous fiber-reinforced, thermoplastic composite panels. Some of the 65 percent E-glass reinforced panels contain a scattered core, recycled from the edge trim and off-fall generated during the manufacturing processes for this and other weight-saving and fuel economy-improving products that Ridge Corp. fabricates.

The end use of the product is an aerodynamic device deployed on the rear end of a Class 8 trailer. The life expectancy of the product is 10 to 15 years. The device is deployed while the trailer doors are closed and the trailer is in mobile operation. When the trailer doors are opened and freight unloaded, the product collapses. The trailer doors swing towards the side of the trailer impacting and compressing the device about its hinges, collapsing the gas springs and folding completely to allow the doors to open completely. When the trailer is ready again for operations, the doors are closed and the device springs back open and into aerodynamic shape. The continuous fiber laminate provides weight savings over traditional material used in the trailer industry for aerodynamic devices, including HDPE and similar materials, aluminum-skinned HDPE-cored materials and other competing composite materials.

Lightweight Composite Air Cargo Container Lowers Lifecycle Costs

ACE – Market Growth Category: Composites Sustainability Award

Submitted by: Cargo Composites

The AeroBox is a light-weight 58-kg/123-lb air cargo container used in the belly of wide-body aircraft to transport baggage, mail and cargo. The low weight of this unit saves approximately $1,250 per year in fuel and 7,800 kg/17,196 lb of CO2 emissions compared to the 82-kg/181-kg aluminum container it replaces. The innovative thermoplastic composite honeycomb panels not only produce a lighter structure, but greatly improve durability. Repair rates of this material in this extremely rough handling environment are one-quarter those of aluminum, leading to a lower life cycle cost. The 100 percent recyclable panels are thermoformed at the edges to create a structural corner when assembled. This eliminates the need for damage-prone aluminum extrusions and greatly reduces the overall parts count. With more than 18,000 of these containers now flying in worldwide commercial airline fleets, the estimated annual total fuel savings is more than 25 million liters/6.6 million gal and CO2 savings are 1,476 metric tons/3.25 million lb.

Says Tom Pherson, president, Cargo Composites: "The most difficult aspect of this application was scaling up to the capability to produce more than 10,000 units per year in a cost-effective manner. This container is an FAA Class II flight critical device. All of our manufacturing procedures, materials and supply chain had to be coordinated in such a way to produce a high-quality, low-cost product. Part of this challenge was to convince customers that a purchase cost premium over aluminum containers would provide them the ROI [return on investment] from fuel and maintenance savings. During the early stages of this growth, orders came in fits and spurts creating very interesting supply challenges."

MTI Valve Perfects the Vacuum Infusion Process

ACE – Manufacturing Category: Equipment and Tooling Innovation Award

Submitted by: German Advanced Composites Inc.

One of the most important elements in producing high-quality vacuum infusion parts is to control the compaction of the preform during the infusion process in order to achieve an optimal fiber volume fraction. The MTI valve uses the physical laws of hydrodynamic and hydrostatic to control the in-bag pressure. When plugged into the resin inlet line, its internal mechanism automatically adjusts the pressure within the resin inlet tube by a defined value. This keeps the net compaction pressure of the layup in a range that is decisive to achieving an optimal fiber volume fraction.

Using the MTI Valve in conjunction with the MTI hose further creates a closed hydraulic system that is self-regulating in terms of resin flow management, leaving less room for failure and increasing the ability to repeatedly achieve void free laminates. The MTI valve, in conjunction with the MTI hose, eliminates the need to time the clamping of the evacuation and/or resin inlet line since the process regulates itself.

Says Juergen Schilden, president and CEO of German Advanced Composites Inc., "The MTI valve is not reusable. To be able to provide this item at a reasonable market price we had to find a smart design that does not use expensive or complex technical items. Controlling the system pressure by utilizing a preloaded spring that presses a ball in a spherical calotte was the simpliest and at the same time most effective solution."

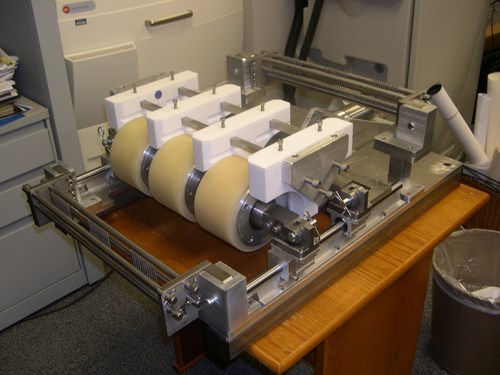

Near Dripless Resin Impregnation Applicator for Filament Winding Applications

ACE – Manufacturing Category: Equipment and Tooling Innovation Award

Submitted by: TSE Industries Inc.

TSE has pioneered the development of a brand new method of reinforcement (glass/carbon fiber) impregnation during filament winding. This method of impregnation not only minimizes process waste, but also maximizes the effective impregnation of reinforcement strands using minimal quantities of resin. TSE's patented technology ensures better laminate quality through consistent impregnation. Not only can the roving tension be automatically controlled, but also the ratio of reinforcement to resin (LOI) can be easily and consistently controlled. The near dripless applicator helps optimizes resin impregnation, consistently providing a 70 to 80 percent glass-to-resin ratio. The TSE applicator can be cleaned in place and put back in service in just 7 to 10 minutes.

Says Mark de Souza, director – R&D, TSE Industries, "Resin impregnation in glass has always been a gray area as conventional baths either dip strands into resin (W bath design) or let a film of resin be picked up from a roller. All of this is reliant on the chemistry of the glass coating (sizing) to ensure that all fiber strands in a tow are effectively coated with resin and thus form secondary bonds with the fiber. Our new patented applicator design force-infuses resin into the strand as the pass through the rotating elastomer coated rollers thus ensuring better impregnation. The most difficult aspect of this design was to ensure that limited quantities of resin are effectively used in the impregnation process at high speed, and also to ensure that cleanup of the applicator does not exceed conventional bath systems clean up times.

SUPERPILE — Pultruded Fiber-Reinforced Polyurethane Pipe Pile

ACE – Market Growth Category: Infinite Possibility for Market Growth Award

Sumitted by: Creative Pultrusions Inc.

SUPERPILE is a pultruded fiber-reinforced polyurethane pipe pile that is used for bridge and dock fendering, vessel mooring, guide and foundation piles. Markets include bridge pier protection, commercial and residential docks, vessel fueling piers and foundation piles. SUPERPILE is made with polyurethane resin and E-CR fiberglass in the form of roving, stitched fabrics and continuous filament mat. SUPERPILE has the capacity to absorb large amounts of energy when impacted by maritime vessels and exhibits lower embodied energy than traditional steel and concrete piles. SUPERPILE will not rot, rust or spall or succumb to marine borers.

Union Station Pavilion

ACE – Design Category: Most Creative Application Award

Submitted by: Studio Twenty Seven Architecture

The information and ticket pavilion for Union Station’s (Washington, D.C.) new intercity bus terminal achieves required functionality with a colorful, modern design, transforming a concrete parking deck into an inviting passenger waiting and transit area. Fiberglass and foam core sandwich panels enabled low-cost tooling and an extremely short 32-day timeline, providing both architects and contractor a solution not possible with traditional materials. Customized building skins that integrate structural, waterproofing and thermal functions, reducing total elements yet enabling unique textures and shapes offer huge market potential. The very creative, low-cost approach to texturing of facades showcases composites’ endless capacity for solutions.

The end-use market is construction and architecture. The product is used both as a building and as an artistic/architectural element to help redesign and re-purpose the existing train station/bus station space and structures. Composites enabled a very fast fabrication combined with significant customization of color (yellow and silver), shape (“inverted hull” ellipsoid) and texture (Morse Coded song lyrics translated into raised dots and dashes). Due to the myriad approaches possible with composites, low-cost “stick built” tooling was possible, saving hundreds of thousands of dollars vs. CNC-machined foam plugs and molds. Composites’ nearly endless molding process options allowed the Morse Code textures to be created very cost-effectively thru CNC-machined sheets of MDF (medium density fiberboard), gelcoating, standard fiberglass lamination and coring techniques, and an ingenious vacuum solution for releasing the composite panels from the densely dimpled MDF molds. The structure was shipped via truck and installed overnight, complying with schedule limitations from the station’s heavy use and traffic as well as the contractor’s need for no interruptions to its work on other parts of the overall renovation. The low mass of the structures made them easy to unload with a forklift (no crane required) and move into place using wheeled dollies.

Lightweight Multifunctional Conductive Composites – Antennas

ACE – Design Category: Most Creative Application Award

Submitted by: Conductive Composites

Conductive Composites bridges the capability gap between composites and metals by enabling electrical conductivity and electromagnetic performance through integrated multifunctional materials. Lightweight composite antennas show how advanced materials will enable the next class of applications for the composites industry. By using metal-composite hybrid constituents, the advantages of both materials are realized in a single integrated solution that provides the weight, structural, manufacturing and environmental advantages of composites with the conductivity and electromagnetic capabilities of metals.

One of the strongest value propositions of composite technology is in weight savings, strength, and environmental performance. One of the weaknesses of a typical composite is its very poor electrical conductivity. The company’s approach takes advantage of hybrid materials systems that can integrate the advantages of composites (weight, strength, corrosion resistance, etc.) with the advantages of metals (electrical conductivity and electromagnetic capabilities) into a single integrated materials system. There are no secondary processes, and no conductive coatings to scratch, peel, or corrode – all the functionality is provided by precisely coated nickel CVD-coated carbon fibers and scrims that can be used in many standard composites manufacturing processes. Whether for spacecraft, aircraft, shipboard, automotive or even mobile soldier, these significant weight savings translate into energy savings or improvements in mission capabilities. A broader advantage is that lightweight electromagnetic composite capabilities are now available that previously simply did not exist. This antenna is only one example of this disruptive composite technology.

The antenna was designed by VaporShaft and Antenna Product Corp. CVD-coated fibers and scrims were manufactured by Conductive Composites; prepreg was manufactured by Patz M&T; the tube was fabricated by North Fork Composites; the antenna was fabricated and assembled by VaporShaft; testing was done by Antenna Products Corp., Science Applied Research Associates, and DNB Engineering, under contract to the USAF. This effort combined small business, primes, government entities, independent test labs and the entire manufacturing supply chain for the product. These collaborations have resulted in a complete supply/validation chain that has vetted the product and is ready for production and market deliveries.

This product fits within a whole class of applications that are enabled by conductive composite materials, which also includes lightweight shielding cases, reflectors, cable shields, X-ray-translucent medical wiring, conductive thermoplastics and composite energy storage systems.

3-D Printing Continuous Carbon Fiber Composites

CAMX Awards

ACE – Manufacturing Category: Material and Process Innovation Award

Submitted by: MarkForged

Designed to overcome the strength limitations of traditional 3-D-printed materials, the Mark One 3-D printer is the first 3-D printer designed to print continuous carbon fiber, Kevlar and fiberglass. Using a patent-pending CFFTM (Composite Filament Fabrication) process, MarkForged’s blend of thermoplastics immediately hardens during printing. CFFTM offers the opportunity to dramatically shorten design cycles and enables high-resolution fiber placement. The system uses a proprietary thermoplastic matrix that also offers excellent interlayer adhesion and high impact resistance not found in thermosetting resins. Based on in-house three-point bending tests done on an Instron universal testing machine, Mark One carbon fiber CFF 3-D-printed beams have a higher strength-to-weight (specific modulus) than 6061 T6 aluminum. Further, the user can easily turn billet parts into sandwich panels with printed-in core material. This greatly increases strength-to-weight while adding the desired panel stiffness to external facing components.

NASA-Boeing Composite Cryotank

CAMX Awards

Submitted by: NASA Glenn Research

The NASA Composite Cryotank Technology Demonstration team successfully collaborated with Boeing (Huntington Beach, Calif. and Tukwila, Wash.) to design, fabricate and test an all-composite cryogenic fuel tank for launch vehicles, paving the way for lower-cost access to space. These designs achieved a 30 percent weight savings and a 25 percent cost savings, allowing insertion of higher mass payloads to low-earth orbit and beyond. A number of technology firsts included thin-ply fiber placement of a large test article (5.5m diameter) using out-of-autoclave (OOA) processing, and successful cure of a hybrid (thick and thin plies) laminate. Ultimately, the largest automated fiber placement (AFP), OOA, composite tank was fabricated as a result of this effort. It was also the first successful demonstration of an all-composite bolted sump/forward cover joint. NASA analytical capabilities facilitated the rapid development of models for AFP processes, and accurate prediction of structural response in a series of tests using liquid hydrogen (LH2) to thermally cycle the composite tank through various pressure ranges. OOA processing permitted as much as a 20 percent reduction in the power requirements compared to autoclave processing. The NASA Space Launch System (SLS) is being built and the use of composite cryotanks in the upper stage provides additional payload capacity. At the current SLS configuration of 8.4m, this warrants as much as 1,400 kg of added payload.

A composite cryogenic tank fabricated at Boeing by the NASA/Boeing team, containing several thousand gallons of liquid hydrogen, was tested through a series of pressure and three temperature cycles ranging from ambient down to -252°C. The sub-scale (2.4m) tank went through three thermal cycles, three pressure cycles to 135 psi, and an additional 19 pressure cycles to 100 psi. The strain gauge measurements for all cycles met the expectations of the NASA/Boeing analysis team. To realize weight savings, the design uses a 1-piece tank shell without belly band joint. The team also successfully demonstrated the use, breakdown and extraction of an all-composite breakdown tool.

Natural Gas Storage: Connecting Safe, Low Cost Energy to People Who Need it Most

CAMX Awards

Submitted by: Spencer Composites Corp.

Spencer Composites Corp. (SCC) teamed with Pangaea Energy Limited (PEL) to create a natural gas storage system for residential cooking and home heating that not only improves safety, but that significantly reduces fuel costs. Although natural gas is one of the cleanest burning and most abundant energy sources found in nature, it is greatly underused due to a lack of economical transportation, storage and utilization technologies in resource-restricted areas of the world. Until recently, no technology other than pipeline delivery enabled natural gas to be used in this sector. This innovative carbon fiber pressure cylinder, developed using absorbed natural gas (ANG) technology, operates at less than 600 psi and has the potential to enhance the lives of millions.

This portable natural gas cylinder is equivalent in energy content to a commercial 3-kg liquefied propane gas (LPG) cylinder and is about the same size. The Spencer vessel holds 125 scf of gas, which should be sufficient for one week’s usage by a household for its cooking needs. To fill this cylinder in the U.S. or Indonesia would cost about $1.00 to $1.40. This is approximately one-quarter the price of an equivalent amount of LPG. The composite container is similar in size, but lighter than an LPG cylinder, which is fabricated from steel. The composite container is more expensive, but quickly pays for itself in fuel cost savings.

The composite cylinder uses a polyethylene liner with a carbon fiber overwrap, which minimizes weight and maximizes strength. An outer shell protects the inner cylinder and provides a method of standing the cylinder upright, like an LPG container. The cylinder and outer shell are both filament wound using a common epoxy resin. An aluminum or brass boss is wound into the cylinder at one end. The second technology used for this system is ANG. ANG utilizes a process that accumulates gas on the surface of a solid, such as activated carbon material, which allows for the storage of natural gas at substantially higher volumetric capacities than pressurized storage using compressed natural gas (3,600 psi). Because ANG does not require cooling or high compression, the infrastructure for gas processing and loading has significantly lower capital and operating costs. Another benefit of the low pressure requirement of ANG is that it can be better used in residential applications. For example, a low-pressure ANG storage container can be filled with natural gas from a domestic pipeline using a small single-stage compressor.

Says Brian Spencer, Spencer Composites: "Since this product is intended for use by families in third world countries where available family income is low, we need to make this tank as low cost as possible — less than $30 (USD). We are working toward that goal with blowmolded PE liners and low-cost carbon fiber. We have not as of yet reached our ultimate cost goal, but we are close. We intend to provide the first production lot of these tanks for free to a small community in Indonesia (less than 1,000 households)."

Sustainable Upcycling of Waste and Scrap Prepreg for Commercial End-Products

CAMX Awards

ACE – Design Category: Innovation in Green Composites Design Award

Submitted by: M.C. Gill Composites Center, University of Southern California

Each week thousands of pounds of uncured scrap and waste prepreg from the aerospace industry are disposed in landfills. Researchers at USC have demonstrated a sustainable, commercially viable, and environmentally responsible process of converting this otherwise-landfilled material into dozens of innovative artistic and structural end-products spanning several industries such as consumer and sporting goods, automotive and aerospace components, construction material, shipping containers and medical devices. The raw material form comprised of this scrap, Infinipreg, and the associated portfolio of finished products, helps open up new markets to composite materials and drives down the cost for existing composites-based products.

Unlike recycling and fiber-reclamation efforts that are aimed towards end-of-life parts, which for an aircraft might be a 30-year lifespan, the issue of prepreg scrap reuse has to be dealt with immediately as it is continuously generated. Products made from this scrap prepreg can enter the market at very low price points because of the very low starting material cost and simple manufacturing routes compared to virgin prepreg composites and its associated manufacturing routes that are sometimes cost-prohibitive for certain applications. In this way, scrap prepreg based parts can penetrate and open up new markets and applications.

Scrap prepreg is first roughly sorted and then mechanically cut into consistent sized chips. The roll form of Infinipreg is created by compressing these scrap chips under controlled temperature and pressure to create a smooth and flat sheet. By strategically varying the chip geometry, orientation, composition and consolidation parameters, Infinipreg plies can be customized to target particular thicknesses, areal densities, and mechanical properties. Infinipreg plies are pliable and drapable. While Infinipreg can be consolidated via vacuum bagging and create parts that resemble VBO-processed laminates, it is best suited to open or closed compression molding, thereby eliminating the need for bagging consumables and the resulting waste stream. It brings to bear several other advantages. Lengthy room temperature vacuum holds and debulk cycles are not required, and temperature ramps at least an order of magnitude higher than manufacturer recommended values can be used leading to faster processing times. The scrap prepreg can be completely tack-free and well beyond its out-life and still result in excellent quality parts. Residual stresses and spring-in is less of an issue because of the mobility of the individual chips. Manufacturing with Infinipreg does not require skilled labor. Finally, Infinipreg based parts possess a very unique and aesthetic surface appearance by virtue of the varying chip orientation, with each chip reflecting light slightly differently.

Says Gaurav Nilakantan, Ph.D., senior research associate, Dept. of Chemical Engineering & Materials Science, University of Southern California: "While we have the requisite technical expertise and creative ideas as well as a long-term vision for this effort, the biggest barrier remains changing and steering the industry’s mindset towards necessitating re-use efforts and preventing landfilling. I believe that will happen slowly over time and with legislation and hopefully our showing at CAMX will help spur that along."

The VX-1 KittyHawk Blended Wing Aircraft

CAMX Awards

ACE – Design Category: Innovation in Green Composites Design Award

Submitted by: VX Aerospace

The VX-1 KittyHawk is an innovative new aircraft with looks and performance that will remake the light aircraft landscape, manned or unmanned. The aircraft has more usable internal volume and payload capacity and improved aerodynamic efficiency. A stellar advantage of the increase in internal volume is the ability to incorporate existing technology compressed natural gas (CNG) as a fuel source, which will reduce the operational fuel cost by a factor of three. Equally important is the structural efficiency. The basic airframe consists of just six components, and there are no highly stressed parts in the design.

One of the major advantages of advanced composites manufacturing is parts reduction. Reducing the number of discreet elements of any assembly decreases the time and cost to manufacture. The VX-1 KittyHawk has a radically low parts count. The basic airframe consists of 4 ribs, an upper skin and a lower skin. In fact, the aircraft does not use a wing spar as it is not necessary. The VX-1 also requires large-area unsupported panels. New material developments in this area are being implemented in the realization of the KittyHawk design. Most notable is the use of Chomarat's new thin-ply, non-crimp fabric, called C-Ply.

Abandoning the traditional quasi-isotropic lay-ups or “black aluminum,” C-Ply enables laminate designers to vary the fiber angles between plies and to take advantage, where appropriate, of low angles that can be more efficient in load sharing. Combine these features with the concept of thinner plies with evenly spread fibers and the benefit is increased toughness and lighter weight.

The VX-1 is in its flight testing phase of development. The first flight of the sub-scale aircraft took place on June 6, 2014. The second flight will be sometime in August or September. The test aircraft is fully instrumented and data logs just about every aerodynamic parameter conceivable. The data obtained from the first flight matches near perfectly with the data derived from the CFD (Computational Fluid Dynamics) and wind tunnel work at North Carolina State University. This is extremely important. Based on this, changes to the design can be accomplished virtually and their effect evaluated virtually with very high confidence. This fall, VX Aerospace will be doing just that. The goal is the final design configuration for full scale development. It is anticipated that full scale development will take about two years with flight demonstration of the full scale configuration in late 2016.

High-Performance Composite-Based Foundation Walls

CAMX Awards

ACE – Market Growth Category: Infinite Possibility for Market Growth Award

Submitted by: Composite Panel Systems LLC

Epitome Quality Foundation Walls are a high-performance composite-based improvement in lieu of current concrete residential foundations. The unique sandwich panel construction of Epitome foundation walls provides the homeowner with a warmer, drier and healthier living space (R-16.5 insulation value), as well as improved flexibility to modify or finish the basement at their leisure.

For the builder, Epitome foundation walls combine structure, integrated stud cavities for mechanicals, top plate and damp proofing into a single step. Further, the builder can now install a typical foundation in less than two hours with his own crew. Previously, builders could wait up to two weeks for a separate contractor to install a concrete basement. Moreover, Epitome foundation walls can withstand three times the backfill load of a standard concrete foundation wall. They don’t crack, they don’t leak and they provide a superior product at a price that is competitive to current residential building practices.

Epitome foundation walls leverage a number of composite technologies including pultruded connections, insulated foam core sandwich panel construction and leading edge fire retardant technology. EpitomeTM foundation walls also incorporate the first use of a stud cavity in a composite wall, which gives the wall superior structural performance and seamless integration into current residential building practices.

Ultra-lightweight Composite Towers for Floating Offshore Wind Turbines

CAMX Awards

ACE – Market Growth Category: Infinite Possibility for Market Growth Award

Submitted by: Ershigs, University of Maine

It is estimated that more than 2,500 GW of untapped wind resources exist off U.S. coastlines. In perspective, the current total US generating capacity for all sources is about 1,100 GW. Unfortunately, the majority of offshore wind resources exist in waters too deep (>200-ft) for ocean floor-anchored wind turbines. Thus, in order to capture deep water wind, a floating turbine system is required. Employing a composite tower in this application delivers two significant advantages over traditional steel towers: up to 50 percent weight reduction in tower weight resulting in substantial hull weight savings; extended service life via superior fatigue and corrosion resistance.

The 1:8 scale VolturnUS composite prototype deployed in June 2013 off the coast of Maine (and still in service) is the first grid-connected, offshore wind turbine in the Americas and the first turbine anywhere in the world (land-based or offshore) to employ a composite tower. A full-scale turbine/composite tower is currently being designed by the Maine Aqua Ventus team under a DOE grant for deployment off the coast of Maine by 2017. This design has already been awarded an “Approval in Principle” from the American Bureau of Shipping.

A typical 500-MW offshore wind farm (comparable to land-based farms) would employ approximately 100 utility scale turbines (4.5 to 6 MW each). With each turbine using a 275-ft tall composite tower comprised of some 300 tons of fiberglass laminate, the total mass of a typical offshore wind farm surpasses 30,000 tons of fiber-reinforced plastics (FRP)

Selection of composite materials for floating, offshore wind turbine systems will deliver a ~5 percent reduction in the Levelized Cost of Energy (LCOE) over a steel tower within a standard 20-year deployment period (maximum service life of a steel tower). This is accomplished via ~50 percent tower weight reduction/corresponding platform reduction (1 lb of tower reduction equals 2 to 3 lb of platform reduction) and marinization savings (corrosion resistance). Final fabrication of the composite tower sections near the deployment site results in additional transportation logistics savings associated with steel towers. Extensive fatigue testing also proves the composite tower could be re-deployed several times (up to 60 years of total service) with minimal maintenance.

From Steve Hettick, VP of manufacturing at Ershigs: "The most challenging aspect of the composite wind tower project has been overcoming the paradigm of carbon steel in tower applications. In order to overcome this with a composite solution, it has not only been necessary to demonstrate compelling value benefits, it has been essential to de-risk the technology. To this end, the emphasis of the composite tower project has been to develop robust designs, have these designs independently verified by respected third-party certification agencies, and most importantly to build numerous coupon and large-scale tower sections and perform exhaustive testing to prove the long-term integrity of the composite design. Through collaborative effort, the University of Maine and Ershigs were able to de-risk and validate the composite tower design theoretically and empirically, paving the way for a paradigm shift for composite wind towers.

Independent Rear Automotive Suspension Featuring Continuous Fiber-Reinforced Thermoplastic Composite Springs and Control Arms

CAMX Awards

Submitted by: Polystrand

This automotive suspension showcases the use of continuous fiber-reinforced thermoplastic springs and control arms. The concept can be easily adapted for use in OEM automotive applications and features lightweight, recyclable technology. The cantilever springs and control arms, made of continuous glass-reinforced nylon, can serve simultaneously as springs and structural components, saving weight and allowing consolidation of parts. Since the upper control arms are also flexible members, they are coupled together in this application to counteract body roll during cornering, while increasing roll-induced camber gain, which can be beneficial in this racing application. In passenger car applications, this technique can reduce body roll without adversely affecting straight line ride comfort.

The thermoplastic components displayed in this suspension system were manufactured using readily available equipment. Using a simple compression molding process, cycle times on the order of minutes or even less may be achieved, depending on part volume. Since traditional equipment and methods can be used to manufacture parts with these materials, the greatest challenge will come in educating prospective manufacturers in the development of the manufacturing process parameters (layup, time, temperature, pressure) as well as tooling design.

Says Jonathan Spiegel, senior engineer at Polystrand: 'I would have to say that the most difficult challenge was doing the design work remotely from Colorado while the fabrication was done in Michigan. Fortunately, the measurement and modeling tools that SANLUIS Rassini is equipped with allowed us to work with an accurate virtual model of the chassis here at Polystrand. As with any project, the devil is in the details, and we had our share of those, but we were able to go from design concept to an operating system installed in the vehicle in about eight weeks."

Related Content

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreMicrowave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)