BMI and benzoxazine battle for future OOA aerocomposites

Offering weight, cost and process advantages, these “hot zone” resins are moving down the thermometer and into out-of-autoclave structural applications and autoclavable tooling now dominated by epoxies.

Share

Although autoclave cure isn’t going away, designers of composite aerostructures continue to beat the drum for matrix resins that can be processed out of the autoclave (OOA) by a number of means. Yet they’re also searching for superior resin performance, particularly in terms of damage tolerance. This quest has put the spotlight on bismaleimide (BMI) and benzoxazine resin systems. Each offers an attractive alternative to established epoxies.

BMI excels in high-temperature applications. However, much of its use on the F-35 Lightning II Joint Strike Fighter is due to its superior hot/wet performance at more moderate temperatures, which enables damage-tolerant structures at lower mass than can be achieved with epoxy. At a cost now comparable to high-performance epoxies, BMI is encroaching on epoxy’s recent gains in the OOA prepreg market. At a cost and performance level between standard epoxies and BMI, benzoxazine is increasingly viewed as a way to attack the cost of composite structures throughout the supply chain, not only because of its room-temperature stability and processing advantages, but because it also satisfies complex structural demands and meets supply, surface finish and health and safety requirements.

OOA BMI: Drivers and difficulties

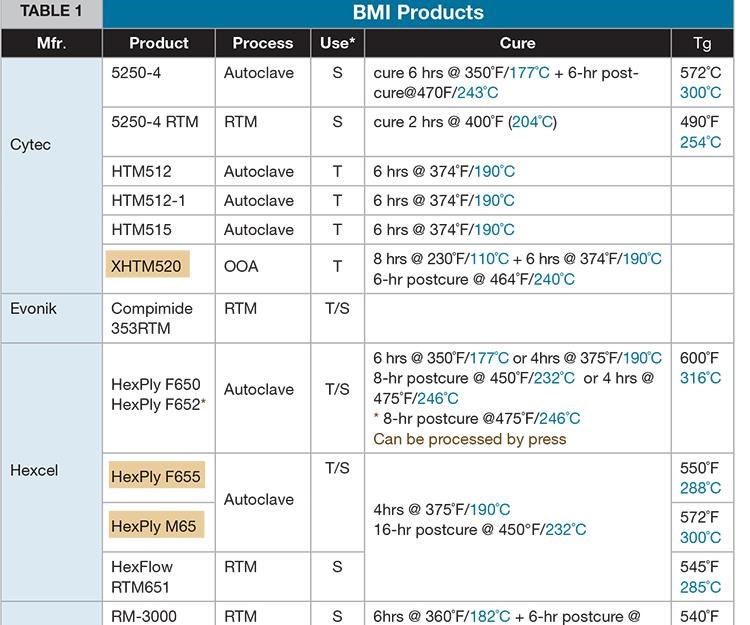

In January 2011, HPC reported the challenge from John Russell, then Manufacturing Science and Technology program manager at the Air Force Research Laboratory (AFRL, Wright-Patterson Air Force Base), that development of OOA BMI “needs to be a goal for everyone.” Three years later, four such systems are commercially available (see Table 1, at left). Dr. James K. Sutter, materials lead for large-scale composite structures at NASA Glenn Research Center (Cleveland, Ohio), has evaluated many OOA BMI systems, and presented the results at recent SAMPE Tech conferences and High Temple Workshops (see “High Temple Workshops" at the end of this article or click on its title under "Editor's Picks," at top right). “When I surveyed the industry with regard to BMI development in 2011, only three companies responded that they had an OOA system to meet our challenging requirements,” he reports. One was Stratton Composite Solutions (Marietta, Ga.), whose BMI-1 resin is now used in resin transfer molding (RTM) and vacuum-assisted RTM (VARTM) more than in prepreg. The company is developing a BMI foam for high-temperature tooling board. The other two suppliers, TenCate Advanced Composites (Nijverdal, The Netherlands, and Morgan Hill, Calif.) and Renegade Materials Corp. (Springsboro, Ohio), have since made significant product improvements as they’ve worked with NASA.

“OOA BMI is attractive because it enables affordable, lightweight tooling with excellent machinability and durability,” says Sutter. “The same tools made from Invar would be at least three times heavier and more costly, while epoxies cannot meet the temperatures or durability required.” NASA is also interested in the ability to make very large composite launch vehicle structures with higher service temperatures. Sutter explains, “For every 50°C [90°F] increase in Tg we can take out 1,000 lb [454 kg] in thermal protective system (TPS) weight.”

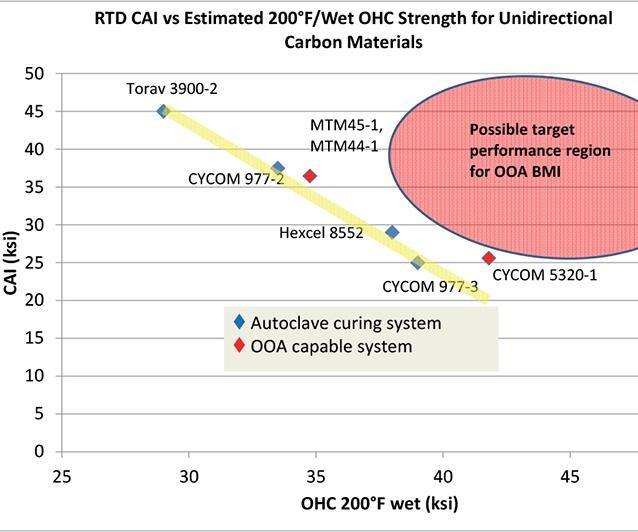

According to Chris Ridgard, associate technical fellow at advanced materials supplier Cytec Aerospace Materials (Tempe, Ariz.), the use of BMI is being driven not just by tooling and applications where service temperatures exceed 350°F/177°C, but also by the increasing use of composites in structures that need improved hot/wet and open-hole compression (OHC) performance at moderate temperatures, such as 80°C to 120°C (176°F to 248°F) (see graphic at left). Ridgard details, “Most of the BMI structures on the F-35 use it because it outperforms epoxy and enables stronger, lighter weight parts.” Stratton Composite’s owner, Bob Stratton, also touts BMI’s better resistance to fluid ingress and gives supporting data for its superior strength retention: “BMI can offer a room-temperature OHC of 52 ksi (359 MPa) and at 220°F (104°C) it is still 49 ksi (338 MPa), where a typical structural epoxy goes from 40 ksi to 30 ksi (276 MPa to 207 MPa) or below at the same temperatures.”

Previously, BMI was thought to be too expensive. “But now,” Stratton asserts, “BMI can be processed at the same cost as high-temperature epoxy resins.” NASA’s Sutter quotes $75/lb for carbon fiber/BMI prepreg, compared to $70/lb for intermediate-modulus (IM) carbon fiber/epoxy prepreg. Stratton cites BMI’s long cycle times on programs such as the U.S. F-22 jet fighter, an F-35 predecessor, as a significant cost issue that is now being addressed. “Cytec materials used on the F-22 required a 13-hour autoclave cycle because they had a six-hour cure,” he recalls. “However, we have demonstrated a cycle time of less than 3.5 hours using the OOA Quickstep process.”

OOA BMI for tooling

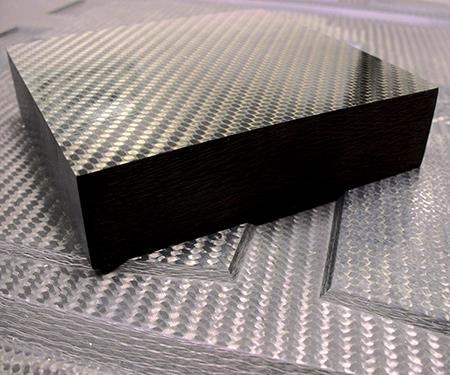

Cytec’s Industrial Materials business has released a new OOA BMI tooling system, HTM520, that features a standard 375°F/190°C cure and postcure options at higher temperatures, with good machinability. Having withstood more than 200 thermal cycles between 20°C/68°F and 177°C/350°F with no microcracking during tests, it also offers what is expected to be a long service life (see opening photo).

Ridgard discusses the difficulties in developing an OOA BMI system. “If you look at why BMIs don’t process as well out of autoclave, you see two factors,” he points out. “First, OOA epoxy prepregs have been designed with evacuation channels” — less than 100 percent impregnation provides dry fiber paths — “so that you can edge breathe the laminate, whereas BMIs tend to flow too much and close off such evacuation channels. Second, the high levels of vacuum used in the production of aircraft structures tend to volatize some of the resin components; thus, the volatiles in the resin must be controlled because there is no autoclave or RTM pressure to push them back into solution.” Ridgard says Cytec has achieved the necessary control of flow and volatiles in its HTM520 system, which also results in better cured-ply thickness control. “If you push the viscosity up, the system is more stable so that resin does not flow all over the place. The tighter rein on thickness can also result in significantly reduced shimming and assembly costs for structures.” Ridgard says it would not surprise him to see a flow-controlled structural BMI based on HTM520 used with an autoclave because it gives that much better part accuracy, which is critical for most aerospace structures.

But what about applications beyond tooling? Cytec’s BMI product manager, Mark Ostermeier, answers, “Cytec has a strong interest in using similar materials for structural applications. There has been huge growth in OOA epoxy materials, which are moving toward higher cure and service temperatures.” That said, Cytec has seen mixed industry interest, with some requesting BMI performance using vacuum-bag only processing while others want only significantly improved notched properties.

“These could go hand-in-hand,” Ostermeier allows, “but there is no specific program demanding such a product.”

A potential fifth source, Hexcel (Stamford, Conn.), is working to develop an OOA BMI prepreg with thermal, mechanical and automated-layup capabilities equivalent to its autoclave-cure M65 product, but with enhanced toughness, targeted primarily for aerospace primary structures but also for vacuum-bag only (VBO) tooling. “We can produce void-free OOA parts,” claims Hexcel chemist Bob Buyny. “Now, it’s a matter of fine-tuning for specific programs and being ready to scale up production.” Although Hexcel has definite program targets, there are, thus far, no set timelines for qualifications.

Benzoxazine: The contender

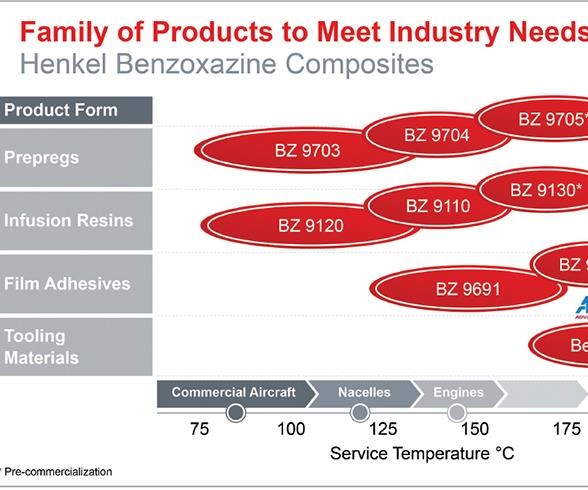

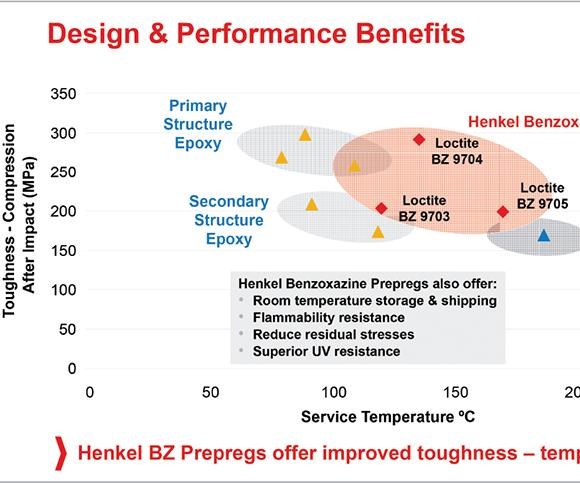

Benzoxazine was discovered in the 1940s. Huntsman Advanced Materials (Basel, Switzerland, and The Woodlands, Texas) began working with it in the late 1980s, and Henkel AG & Co. KGaA (Bay Point, Calif.) followed a decade later. Even though benzoxazine was qualified for printed-circuit boards (PCBs) very quickly in 2000 — it was one of the few readily available nonhalogenated materials that met all of the performance requirements — systems for structural composites weren’t commercialized until 2008. Huntsman sells benzoxazine building-block components to prepreggers, resin formulators and adhesives manufacturers, while Henkel offers a range of formulated prepregs, infusion resins and adhesives (see charts, at left).

“This market has been slower to develop,” explains Huntsman’s composites marketing manager, Carl Holt, “because of the conservative nature of commercial aerospace and the extensive background epoxies have, including material databases.” Another difficulty is that benzoxazine can require cure temperatures higher than the 350°F/177°C standard for aerostructures. Huntsman observes that benzoxazine processing temperatures and times can be varied widely using many different catalysts. Through its development of proprietary catalysts, only two of Henkel’s six benzoxazine systems — three for structural prepreg and three for structural infusion — require a cure over 200°C/392°F. The others cure at close to 177°C/350°F.

Formed by reacting phenol, formaldehyde and amine, the chemistry of benzoxazine is unique in that its additive reaction results in ring opening polymerization (ROP), which produces a high molecular weight polymer and imparts near-zero cure shrinkage and two other key features: (1) it creates a reactive site that makes benzoxazine an über-reactive polymer for hybridizing with other resins, including epoxy, phenolic and BMI; and (2) it enables benzoxazine to polymerize with itself (homopolymerize) to form polybenzoxazine thermoset networks very similar to phenolic. Roger Tietze, a senior scientist technologist for Huntsman, points out, “This is why you get phenolic type properties without the condensation reaction which makes phenolic so difficult to process.” David Leach, Henkel’s global composites segment manager, explains, “The processing is basically the same as epoxy, and you don’t have the issues with voids during cure that must be managed with phenolics. In addition, the heat of reaction is lower than epoxies.” Henkel claims that a 19-mm/0.75-inch thick, 150-ply laminate can be cured with a 5°C/min (9°F/min) ramp rate without an uncontrolled exotherm.

Between epoxy and BMI

“There is a lot of interest because of the material’s advantages,” says Holt. These include high stiffness, excellent thermal properties (high Tg), lower moisture absorption and better flammability resistance (high char yield) than epoxies. Leach points out that benzoxazine also has better resistance to ultraviolet (UV) radiation than epoxies, with cured resin showing no discoloration, chalking or degradation after 95 days in outdoor exposure.

Although reports from university studies show exotic benzoxazines with Tg as high as 300°C to 350°C (572°F to 662°F), Tietze says more common formulations exhibit a glass transition between 150°C and 250°C (302°F and 482°F). Like BMI, higher Tg systems have increased molecular weight and crosslinking, which gives them higher modulus and service temperature but also results in brittleness, so they need to be toughened to prevent microcracking. Leach explains that the benzoxazine formulation Henkel supplied to Airtech International Inc. (Huntington Beach, Calif.) for its Beta Prepreg tooling system is different than what Airtech offers in its structural products. “They were looking for long tooling life at elevated temperature, so we developed that system with a Tg of 250°C [482°F] for 200°C [392°F] continuous service, obtained via post-cure.” However, he notes that “the benzoxazine formulations we have now are starting to get into the BMI service temperatures.”

That is almost unavoidable because, just like BMI, Henkel’s benzoxazine products are targeted toward epoxy’s shortfall in hot/wet performance. Leach says most epoxies have a maximum hot/wet service temperature of 120°C/250°F. All of Henkel’s benzoxazine products have a continuous service temperature of 120°C or higher and claim excellent hot/wet properties. “Traditionally, designers have been more interested in improved retention of hot/wet properties at 250°F and below,” Leach explains, “but more are finding hot spots that demand higher service temps with the recent trend of increased composites in airframes. We see this as a big growth area in the future.”

Leach says the material cost of Henkel’s infusion benzoxazines is competitive with epoxy infusion resins, while for prepregs Henkel has calculated a $1.09/ft2 ($11.62/m2) advantage in finished part cost, including warehousing, handling, layup, autoclave processing, finishing and repair savings, but he notes that this figure is based on validated customer input and will obviously vary based on the part specifics and the expected production volumes.

Stratton claims that BMI chemistry is not inherently more expensive than epoxies. “Perhaps that’s true,” says Leach, “but that’s not been the experience in the industry, to date.” He notes that the amount of BMI actually flying is small compared to epoxies. Compared to BMI, Leach again cites savings with benzoxazine due to elimination of frozen storage and thawing, but he adds that “there are also process cycle time and ease of layup advantages for both manual and automated placement.”

BMI and benzoxazine in autoclave tooling

One of the most recent advances in BMI resin technology is nanosilica-modified prepreg for autoclave-cured tooling. Its proponents say it offers a longer service life at epoxy’s upper temperature limit — a timely development as manufacturers boost cure temperatures to shorten molding cycle times.

The product, 3M Advanced Materials Division (St. Paul, Minn.) Fortified Tooling Prepreg (FTP) BMI, is now distributed by TenCate as 3M BMI TC-44 Si (Si to denote its silica additive). Although it isn’t formulated for OOA processing, 3M’s BMI is designed to provide a bevy of potential cost-saving performance improvements. According to a paper presented at the 2013 SAMPE Tech conference (Oct. 21-24, Wichita, Kan.), a BMI system loaded 40 percent by weight with nanoscale silica particles showed homogeneous dispersion, even between 7-μm diameter carbon fibers, resulting in a range of enhanced properties. Compared to a similar autoclave-cure BMI prepreg without silica, its through-thickness coefficient of thermal expansion (CTE) was reduced by 15 percent, its linear CTE was reduced by 40 percent and its linear cure shrinkage was cut by 50 percent.

Together, these improvements reduce thermal stresses and part distortion and are expected to significantly limit springback (a material’s tendency to deviate from the molded shape due to cure shrinkage in the composite). A 47 percent increase in Barcol hardness reportedly offers enhanced tool surface scratch resistance and better part surface quality. And there’s more: a 40 percent reduction in exotherm per mass is said to provide improved thermal management, which is especially important for thick-part fabrication. The interlaminar shear strength is boosted 15 percent, while a 118 percent increase in fracture toughness promises reduced microcracking, and moisture uptake is cut by 32 percent. Although hardness is greatly increased, TenCate says machinability equal to that of other BMIs can be achieved with adapted materials and techniques, without lengthening the cycle time.

Meanwhile, nanosilica-enhanced systems that are still in development — described as suitable for both tooling and structures — will reportedly have the same 200 percent increase in tensile modulus but will yield an additional 20 to 50 percent increase in fracture toughness and 10 percent less cure shrinkage. Although these benefits will come with a 20 percent increase in resin density, James Nelson, senior product development specialist for 3M Advanced Composites, explains that the overall density increase in a carbon composite at 60 percent fiber volume is a mere 5 percent.

“Most designers have reconfigured composite structures to drop weight and still retain higher mechanicals with our systems,” Nelson says. When asked why this system was not being marketed as suitable for structures as well, he replied, “From a business standpoint, we decided to first get into markets with quick qualification timeframes — like sporting goods, CNG pressure vessels and composite tooling — vs. aerospace, but we do see aerostructures in our future as we grow.” Nelson claims the cost of these products is competitive with unfilled BMIs and that OOA systems may be developed if there is a significant demand.

Like BMIs, benzoxazines are also making a mark in autoclave tooling. The Henkel benzoxazine resin in Airtech’s Beta Prepreg tooling system reportedly exhibits performance improvements that are comparable to those achieved by 3M in its nanosilica-fortified BMI. Within months of its introduction in 2010, it won its first application at GKN Aerospace (Germany) for carbon fiber T-stringer support tools used in manufacturing the Airbus A350 inboard and outboard wing flaps.

Benzoxazine had already amassed in-service experience via Airtech’s Beta 8610 film adhesive, adopted by a major airframe manufacturer for bonding large BMI tooling assemblies, and Henkel’s qualification of a carbon fiber/benzoxazine prepreg with partner Toho Tenax Europe GmbH (Tokyo, Japan) for the Airbus A380 auxiliary power unit (APU) housing, replacing the original BMI. But the GKN T-stringer support tools, roughly 10-cm by 10-cm (about 4-inch by 4-inch) U-sections measuring 8m/26 ft in length, had to maintain tight dimensional tolerances through an autoclave cure at 180°C/356°F and 9 bar/131 psi of pressure, followed by precision machining on the nonmolded surfaces. They would also be used to meet targeted production rates and thus had to provide long service life without rebuilds or repairs. Henkel’s testing showed 90 percent retention of properties after exposure to 175°C/347°F for 10,000 hours and no evidence of microcracking after repeated autoclave cycling. Springback could not exceed the 1° seen with previous BMI tooling, and GKN was looking for a reduction. GKN’s trial molding of a U-section tool with Beta Prepreg showed a springback of only 0.3°. “Less springback also means you have to add less material as minimum for post-cure machining to tolerances, which reduces time and cost,” notes Jerry Jackson, technical services manager at Airtech.

To minimize impact on other production, GKN sought to autoclave cure more than 100 tools only on weekends. Here is where benzoxazine and BMI solutions differ: Beta Prepreg’s six-month outlife at room temperature met GKN’s flexibility requirements. “Smaller work crews could lay up the tools over a longer period,” says Jackson, “breaking away to do other jobs as necessary, without the prepreg becoming unworkable, and laminated tools could be parked until autoclave slots opened up.” Jackson says the benzoxazine system also enabled more efficient tool fabrication. “The Beta Prepreg had so much more tack, GKN found they were able to spend less time in layup and also reduce the number of debulks.”

Airtech describes Beta Prepreg as cost competitive with BMI but contends its performance and fabrication efficiency benefits can tip the scales in its favor. In addition, because tooling projects are typically completed within a six-month time frame, Beta Prepreg’s ambient storage life eliminates frozen storage requirements. Shipping costs are also reduced. Airtech sees a bright future for benzoxazine-based composites. “It is difficult for people in our industry to make changes in basic materials that are ‘tried and true’,” Jackson notes, “but the benefits of working with benzoxazine are quantifiable.” Meanwhile, Airtech has an OOA infusion Beta system in development.

Benzoxazine’s future

Although BMIs are clearly ahead developmentally and commercially, and some users caution that it has not yet attained the maturity of BMI and still requires development in several areas, including OOA processing, benzoxazines are coming on strong. Henkel has OOA benzoxazine systems for prepreg and infusion, and Huntsman has liquid benzoxazines in commercial development. Dave Nesbitt, president of Matrix Composites Inc. (Rockledge, Fla.), a specialist in the design, development and qualification of complex integrated composite structures, sees potential for benzoxazine. Matrix is working with several customers to put benzoxazine composites into production, but Nesbitt, too, sees a need for continued product development. “Benzoxazine offers a unique blend of properties — the burn resistance and smoke toxicity benefits of phenolic but with the strength and modulus of BMI,” he notes. “That opens a lot of doors.” Indeed, benzoxazine is said to offer the flame, smoke and toxicity (FST) performance of phenolic without its voids and processing difficulties. That has it poised to push large, integrated structures into aircraft and other transportation interiors (see “Benzoxazine: An alternative to phenolic for interior fire safety?" below or click on its title under "Editor's Picks").

However, Nesbitt cautions that those who use benzoxazine “must work through some of its processing challenges, as with any new material.” He adds, “We have had great success at high pressures (>100 psi) in both RTM and autoclave environments, but benzoxazine is more challenging to process at lower pressures typical of VARTM, infusion and VBO curing. These are manageable, though, when appropriate measures are taken to ‘vent’ the outgassing that occurs during cure at low pressure.” That said, Henkel presented its development of a void-free 48-ply OOA-cured laminate using its BZ prepreg and the Boeing-developed double vacuum bag debulk (DVD) process in its “Out of Autoclave Composite Repair” presentation at SAMPE 2013 (May 6-9, Long Beach, Calif.).

“The industry has a comfort level with BMI that is not there yet with benzoxazine,” says Cytec’s Ridgard. “It will be cautious in developing applications to make sure there are no hidden problems like cyanate ester showed with moisture.”

Huntsman’s Holt doesn’t entirely disagree: “It took the industry many years to develop epoxies to meet toughened properties and cure processing requirements.” Benzoxazine, he admits, must negotiate a similar transition, “but there is no reason why it can’t be developed to meet all of these needs.”

Indeed, benzoxazine is demonstrating a unique and almost limitless ability to react with other resins (e.g., epoxy, phenolic, BMI, thiol) and produce hybrid formulations with exceptional properties (see “Benzoxazine + BMI?” below or click on its title under "Editor's Picks"). The ability to truly tailor polymers per application could be revolutionary and afford the next degree of optimization as composites compete with light metals for future airframes.

Related Content

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreRead Next

Renegade Materials demonstrates OOA BMI in wing spar

Renegade Materials Corp. (Miamisburg, Ohio) has developed its RM-3004 out-of-autoclave (OOA) curable bismaleimide (BMI) prepreg for high-performance aerospace applications.

Read More

.jpg;maxWidth=300;quality=90)