Composites the clear choice in telecom tower rehabs

Tower permit difficulties spur repairs/upgrades of aging steel structures.

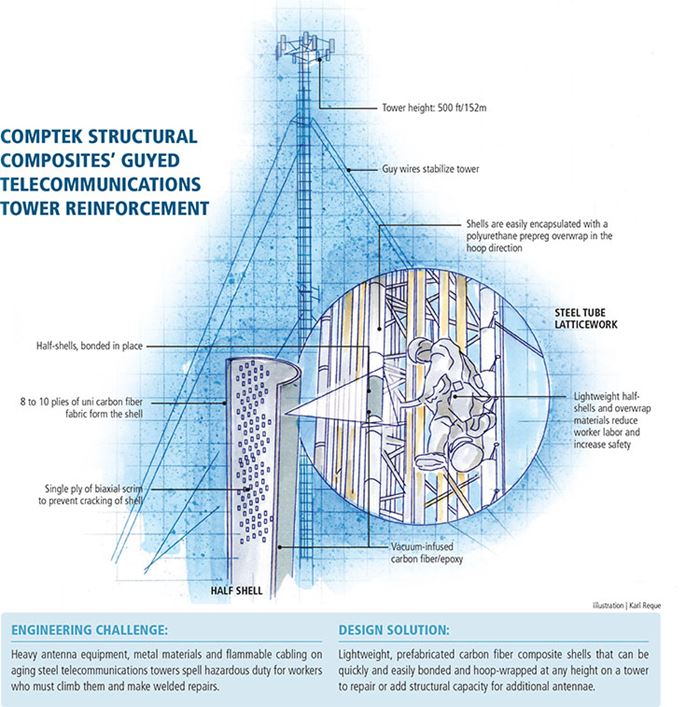

Engineering Challenge:

Heavy antenna equipment, metal materials and flammable cabling on aging steel telecommunications towers spell hazardous duty for workers who must climb them and make welded repairs.

Design Solution:

Lightweight, prefabricated carbon fiber composite shells that can be quickly and easily bonded and hoop-wrapped at any height on a tower to repair or add structural capacity for additional antennae.

More than 100,000 cellphone towers dot the landscape in the U.S. alone. Millions of people depend on their electromagnetic signals every day for communications, and estimates of the need for additional transmission capacity in the next decade run as high as five times the current capacity. However, no one wants a cell tower in their neighborhood. This “not in my back yard” attitude means that operators can’t easily erect new towers. Further, existing steel towers are aging and many are now in need of repair. Tower operators must not only repair towers to extend their service lives, but also strengthen them to carry new equipment as demand goes up among cell phone providers.

Repairs and upgrades, however, involve great risk. Galvanized steel towers support miles of flammable coaxial cables. When workers weld steel jackets or additional structural support high onto the existing structure, welding sparks and slag can ignite the cables, resulting in expensive fires. Plus, scaling the towers for any reason is hazardous, even deadly; many climbers have died in tower accidents.

Structural engineer Jim Lockwood, CEO of Comptek Structural Composites (Boulder, Colo.), knew there was a better way: “A telecommunications company saw an article I had written for the American Composites Manufacturers Assn. Market Development Alliance [now the Composites Growth Initiative], and contacted me. That was our opportunity to introduce composites for the tower repair market.” Twelve years later, Comptek and its spin-off design/build company, Aero Solutions LLC, have the corner on this specialized and successful market.

From monopoles to guyed towers

At first, Lockwood’s customers wanted a way to increase marginally the structural capacity of galvanized steel monopole towers, which are located, for the most part, in urban locations. The monopoles, hollow steel tubes up to 200 ft/61.5m tall, range from 3 to 5 ft (0.9m to 1.5m) in diameter. Comptek’s solution was to bond to the tower a precured pultruded carbon fiber laminate, using structural adhesive. Laminate locations were identified by modeling (described below). This eliminated the risk of igniting the heavy coaxial cables inside the pole and increased tower load capacity, which allowed tower operators to install additional cell phone transmission equipment. But as the work evolved over several years, and as customers demanded much greater structural capacities on their towers — an additional 50 to as much as 100 percent — the laminates had to be thicker, which added considerable cost due to the high volume of carbon needed to achieve the necessary stiffness. Today, Aero Solutions deploys carbon fiber solutions teamed with bolted-on steel plate, he relates, when the higher capacity is required.

Increasing the structural capacity of taller “guyed towers,” however, demanded a different approach. Usually erected in suburban locations, these skeletal structures (see photos, this page) feature slender steel-tube latticework that can soar to heights of 500 ft/154m, kept in place by guy cables. For guyed tower leg applications, Lockwood envisioned lightweight, vacuum-molded carbon fiber half shells to replace conventional split steel pipes that had to be welded onto the slender legs. The cured half shells would weigh only a few pounds and, therefore, could be carried easily by technicians as they climbed the towers, and then quickly bonded around a tower leg, eliminating the need for welding — all of which would enhance installation safety. The precured half-shells also proved to be a reliable repair solution for the steel legs, which can split over time due to freeze/thaw cycles when water enters weep holes. “Engineers at a very large U.S. tower company, Crown Castle [Houston, Texas], understood composites and adhesives, and what they could do for strengthening and repair, and really became a composites ‘champion’ for the tower industry and our approach,” Lockwood says.

Customized for compressive modulus

The primary load on guyed towers, as on monopoles, is wind load, which tends to cause buckling of the tall, thin structural legs. To add structural capacity, then, the carbon fibers must be aligned parallel to the steel legs, and the compressive modulus of the fiber and resin is the key design factor. Lockwood decided to precure a unidirectional laminate shell under controlled conditions to ensure consistent modulus. He designed a simple aluminum shell mold, in a half-pipe shape, and custom-molded carbon composite shells, approximately 20 ft/6.2m long, and 5 inches/125 mm edge to edge.

Actual half-pipe dimensions are customized for each tower. The shells are made with 8 to 10 plies of 9-oz unidirectional carbon fiber fabric supplied by Zoltek Corp. (St. Louis, Mo.) and several other suppliers. A single ply of biaxial scrim is the last ply down, adding off-angle fibers to support and strengthen the unidirectional fibers. The scrim prevents “pinching” or other damage during transport. The lay-up is then bagged, and infused with a toughened epoxy resin supplied by Gurit (USA) Inc. (Bristol, R.I.), and cured at room temperature.

On the tower, two shells are bonded together to enclose target sections of the tower leg using a structural epoxy adhesive fortified with thermoplastic fibers to minimize dripping. The epoxy bond line isolates the carbon from the steel tower, eliminating any galvanic corrosion, explains Lockwood. The final step is to hoop-wrap the joined carbon shells with a one-part, water-activated, polyurethane prepreg overwrap, developed inhouse by Comptek.

To prepare the proprietary wrap, E-glass fabric is prepregged at Comptek’s facility in a humidity-controlled room with the water-activated polyurethane resin, which contains an additive to inhibit ultraviolet degradation. The prepreg is cut and kitted and placed inside a vacuum-sealed bag for transport to the site. After the technician applies the wrap, he simply sprays it with water to initiate cure. The tough overwrap is designed to protect the uni carbon from damage during future equipment installations, and its surface is easily painted in the white/red color scheme mandated by the U.S. Federal Aviation Admin. “The prepreg provides full confinement to the shells,” Lockwood points out. “And it’s durable enough to withstand the clamping force of any future antenna brackets.” It also gives the repair a smooth, low-profile and aerodynamic surface, which cuts wind load — the inspiration, he notes, for the name Aero Solutions.

Game-changing design

To determine exactly where to apply the shells on a tower, a structural analysis is required, typically using tnxTower software from Tower Numerics (Lexington, Mass.), a common design tool for telecom towers. Aero Solutions applies its proprietary inhouse post-processing software, called AeroSoft, to the tnxTower program, to optimize shell placement. “This stiffness-based program tells us, for instance, where the tower is overstressed if a new antenna is going to be installed at the 200-ft [61m] level,” he explains. “The exact location is based on the new equipment and cabling, as well as any observed deterioration.”

The Comptek material solutions implemented by Aero Solutions reportedly have changed the landscape for tower operators. All the materials for a repair job can be transported to a project site in a pickup truck, and climbers can complete a major rehab in as little as one day — a far cry from the time necessary for steel-centric solutions. And, says Lockwood, “We’ve developed a carbon wrap system for repairing monopole tower foundations, where strengthening and repair is often needed. When more steel rods are drilled down into the existing caisson, cracks can occur, which the wrap addresses.”

For Lockwood, the outlook is positive, not only in tower rehab but other markets. “There is a lot of room for composite product development for infrastructure repair,” he points out, adding, “I started this company to create innovative repair solutions for oil and gas pipelines, for refineries, for bridges, and so much more.”

“The tower repair niche is a niche that makes you think of other niches!” he quips.

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

TV tower composite repair: High-rise in Hawaii

Boulder, Colo.-based Aero Solutions LLC performs repairs with composites on a 175-ft/54m tall television broadcasting tower atop a 42-story building in Honolulu, Hawaii.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)