Dark knights: Sleek trimarans surveil the seas

Epoxy-infused patrol boats outperform less nimble and more costly conventional naval craft.

A response to the changing needs of modern navies with greatly reduced acquisition and operations budgets, the Ocean Eagle 43 is a light ocean patrol vessel (OPV) that makes use of modern electronics for multiple missions — many of low intensity but high economic import, such as anti-piracy and surveillance of fishery, oil and gas and other maritime resources. Constructed of composites by Chantier Naval H2X (La Ciotat, France) for shipbuilder CMN (Paris and Cherbourg, France), the new 43.6m OPV benefits from CMN’s 68 years of surface-combatant craft experience and construction of hundreds of advanced vessel designs for 38 navies around the world. Part of the Ocean Eagle’s versatility comes from its sleek and fast trimaran hull, which also offers a beam (width) that can accommodate a landing platform for unmanned aerial vehicles. A renowned shipyard in its own right, H2X’s methods contribute to the trimaran’s favorable performance-to-price ratio and have earned its builder the record for the largest hull ever infused with epoxy resin in one shot.

Designing for efficiency

Conceived by legendary naval architect Nigel Irens, the Ocean Eagle 43 is a descendent of his multi-hull designs, which dominated international sailboat racing for decades. Predecessors include an Irens’ powered trimaran, the 21.3m iLAN Voyager, which still holds the record, set in 1988, for circumnavigating Great Britain without refueling (2,523 km at a fast average speed of 21.5 knots on only 2,000 liters of diesel). A decade later, Irens’ 35m trimaran, Cable & Wireless Adventurer, circumnavigated the globe, shaving 10 days off the 84-day record previously set by the U.S. Navy’s nuclear submarine, Triton.

“It’s taken many years for the world to warm up to this design for an efficient surveillance vessel,” notes Irens, “but it is a perfect application for a trimaran.” The long, slender main hull and diminutive outer hulls (called amas) provide exceptional stability but weigh less and experience less drag than other hull forms of comparable displacement, including twin-hulled catamarans. “The trimaran offers the greatest range … due to its very low wetted surface area,” he explains. “What you get is a top speed of 30 knots for Ocean Eagle, but more importantly, a very economical 20-knot cruise for a 4,828 km range.”

“The Ocean Eagle’s capability is to cruise efficiently for many hours, but then accelerate quickly and pursue,” observes H2X’s head of composites Pierre Lallemand. Its lightweight construction is key to its acceleration and long-range fuel efficiency. Rivoyre Ingenierie (Sophia Antipolis, France) assisted in completing the laminate design, which uses mainly glass fiber/epoxy sandwich construction. “Everything … is cored and infused,” says Lallemand, “except for monolithic areas near the bottom of the hull at the front of the boat.” Carbon fiber was used here as well as in high-load areas like stringer caps and in the arms that connect the amas to the main hull. “The composite structure is well proven,” says Irens, “and essentially uses unidirectional reinforcements along the top and bottom of the ‘shoebox’ formed by the hull and deck.” He adds that off-axis reinforcements (±45°) are used to handle the shear/torsion between the top and bottom.

Preparing for dark hulls

Destined for naval duty, the composite structure would be finished with standard dark gray paint, which reduces ship visibility on the horizon but also absorbs heat from sunlight. That made the glass transition temperature (Tg) of the resin a key concern. Here, H2X drew on its 20-year relationship with epoxy resin supplier Sicomin (Chateauneuf les Martigues, France) to define an appropriate matrix.

“The original Tg specified was 120°C to 140°C, a carry-over from the initial design which called for prepreg,” explains Sicomin’s export manager Marc Denjean. ”However, that would have doubled the cost of the resin and also increased the cost of tooling and postcure.” Fortunately, the design/build team switched to more economical resin infusion processing, for which Sicomin could suggest a system with a lower Tg of 90°C, based on its history with multiple dark-colored, epoxy-infused boat projects. Denjean points out that infusion epoxies with a Tg of 80°C are readily available, but he believes that is too low for dark hulls, risking not only print-through but a loss of mechanical properties over time that could result in laminate or structural failure.

Sicomin also gathered differential scanning calorimetry (DSC) and dynamic mechanical analysis (DMA) test data to support its confidence that a sufficiently high heat distortion temperature (HDT) would be achieved with the 90°C Tg resin, and that it would ensure that aging would not be a problem.

“With time, the Tg will decrease a little,” Denjean explains. “This is what we refer to as the wet Tg, and it must stay above 80°C.” Denjean recounts that Sicomin also asked H2X to make small samples per every batch of mixed resin during the actual infusion “which were then cured with the same history as the boat. These were tested using DSC and DMA to double-check Tg and ensure the mix ratio was respected.” This also provided complete traceability for the molding processes.

Taking no chances

Despite the main hull’s size, H2X did no flow modeling. “We don’t take too much risk when we infuse,” Denjean explains. “We use numerous feed points and short flow distances between them. But we did do a lot of infusion testing on a large glass table to ensure that all of the different cored laminates would infuse completely, without problems.”

Corecell foam core from Gurit (Wattwil, Switzerland) was used in densities from 80 to 200 kg/m3 and in thicknesses from 20 mm to 40 mm, optimized by location to save weight. “The glass table allowed us to see how the outside skin wet out and how the resin moved as well as the flow speed, which is a vital part of the resin mixing and feed-line arrangement calculations.”

Lallemand and his team tested all of the laminate schedules — for example, hulls vs. floors and junctions between these and the superstructure. “There were many changes we had to make based on this testing,” says Lallemand. “For example, some skins have 4,000g[/m2] of fiber and there were issues with infusing these, so we changed the laminate plan, altering the direction of the fiber to achieve the flow and wetout needed — of course, with designer and naval architect approval.” Here, too, Sicomin provided key assistance, developing 150-mm and 300-mm wide UD tapes especially for infusion of the critical arm structures. Stitching was designed to leave open paths that would encourage resin flow but was balanced to achieve sufficient fiber volume for the required mechanical properties. H2X used 10 layers of these tapes in the arms.

Tests also were run on the epoxy resin, Sicomin’s SR8100 infusion formulation. “We had to test the hardener to ensure that we had the right viscosity and gel time,” Lallemand recounts. “The goal is to have a viscosity low enough to permeate the laminate quickly, but not so quickly that you have dry spots. The gel time must be long enough to enable infusing the whole hull. But you don’t want a gel time so long that there is too much time between completion of wetout and beginning of gel.” This is because the team must still keep watch over the infused laminate under vacuum until gel is complete. Lallemand concludes that an excessively long gel time “wastes time and money and increases risk.”

The epoxy-infused structures also would have to be postcured to achieve full mechanical properties. “We made lots of tests for gel time and exothermic peak temperature to make sure that the postcure process was correct.” He notes that all of the above resin characteristics must be balanced but also must yield maximum mechanical properties and do so without postcuring at too high a temperature. Based on the testing, H2X elected to postcure at 60°C.

The Ocean Eagle 43 trimarans were certified by the French classification society Bureau Veritas (BV, Neuilly-sur-Seine, France) to ensure they met rigorous engineering and quality standards. BV reviews drawings and laminate calculations to make sure the boat structure can handle the loads at its 30-knot top speed in open-ocean conditions. It then performs mechanical property testing on panels supplied by H2X to confirm actual properties. Tests included tensile strength and modulus, porosity and four-point flexure of sandwich panels, among others. BV also visited H2X weekly to inspect construction quality.

Making massive molds

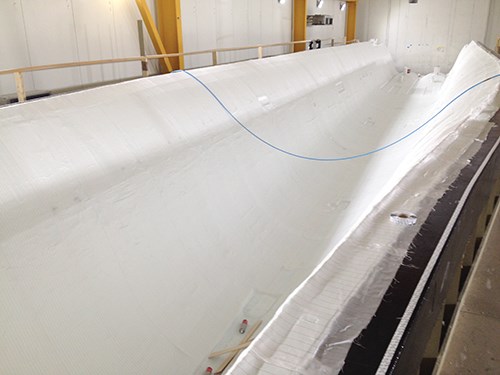

Because H2X had only 9 months to complete and deliver the first boat to CMN, testing work proceeded in parallel with mold fabrication. Although flat panels could be made on a table, the main hull, the amas, and the arms and other curved structures required shaped molds, nine in total. H2X made its own tooling, having the ability in-house to go from CAD drawings to CNC-machined plugs to infused tools. The molds for this project, however, were built differently, formed directly (without a plug) from CNC-cut wood panels that were sheathed with plywood and composite laminates, and then surfaced with tooling paste and sealant. One issue was to ensure the mold was airtight. For previous large, infused epoxy yachts, H2X had simply CNC-cut molds from epoxy tooling board and then coated the surface for vacuum integrity. However, because the main hull mold surface area totaled 300m2, H2X chose the more cost-effective wood construction, but had to adapt the surface treatment for the large size and then test it for airtightness. “We do this by putting the bare mold under vacuum and measure how much the vacuum level drops over 30 minutes.” When it was satisfied with the molds’ vacuum integrity, the team prepared for infusion.

Coordinating infusion

To keep overall construction time to a minimum, the hull, amas, arms and deck parts were layed up and infused in parallel. “We layup and infuse in a temperature- and humidity-controlled cleanroom,” says Lallemand. “For parts that would not fit here, we made temporary enclosures — ‘cocoons,’ which we could air condition and monitor.” Temperature control, he explains, kept resin viscosity low, but not so low that the resin moved too fast. This helped them to avoid resin cure before infusion was complete, and it prevented generation of too much exothermic heat.

Because core materials for the first boat’s main hull — the single largest infusion — were cut in-house, layup of its dry materials stack, including quadraxial and biaxial fabrics supplied by FORMAX (Leicester, U.K.) and SAERTEX (Saerbeck, Germany), took roughly three weeks. But core materials for the second and third main hulls were kitted by Gurit, reducing layup time by 20-30%. “We did not have enough time to do it elsewhere,” says Lallemand of kitting, “but in the future we will try to do this more because it saves us time in preparing the infusion.”

According to Lallemand, organizing such a large infusion — almost 4,000 kg of resin for the main hull — was a challenge. “We had to coordinate the people, how to mix and feed the resin and where the points for this would be.” Several mixing points were prepared along the main hull’s length, and 10 technicians were stationed inside the hull to control resin flow. “They do this by opening valves at feed points, and then when the resin reaches a set point, they close the previous feed valves,” Lallemand explains. “When they open the next feed valves, they check to make sure there are no leaks — which is the main issue — inspecting all of the feed line connections and ensuring there are no air bubbles.”

“The core has a big influence on the infusion,” Denjean contends. H2X used double-cut core, with very thin cuts on the top and bottom that help aid resin flow on both sides. They also used a micro-perforated release film, supplied by Cytec Industrial Materials (St. Jean, France) and distributor Diatex (Saint-Genis-Laval, France). “Thus, an infusion flow web is no longer needed,” says Denjean. “In effect, you combine the peel ply with the flow medium, which is easier to lay down and reduces consumables.” Sicomin supplied micro-perforated PVC foam, used for flat panels such as bulkheads, and provided the release agent used on all of the tools and molds.

The main hull was infused in 5 hours and vacuum was maintained for another 4 hours until gel was completed. This was followed by a 16-hour postcure in a 43m-long by 15m-wide oven at 60°C. The 11m-long amas were infused in two halves and then joined along the centerline. Other large structures included the main deck, the 6m by 15m helicopter deck, the pilothouse/bridge and the 5m-wide by 15m-long arms that connect the amas. “These two large parts are each essentially a box joining the main hull to the floats,” says Lallemand. “The top parts were very complicated and also form one of the most stressed areas in the boat’s structure, so quality here was critical.”

Enabling assembly consistency

Following infusion and cure, assembly began. “There are 106 parts to assemble, all composite,” says Lallemand. “It took several weeks to build all of the structure inside the main hull, including stringers, bulkheads, floors and decks.” Parts were joined by conventional wet layup tabbing, using glass reinforcements supplied by Sicomin, similar to the carbon fiber tapes provided for the arms. Sicomin also supplied the SR8500 hand laminating resin for tabbing and Isobond SR1170 for enhanced bonding in high-stress areas. All of the connections on the outside of the hull were vacuum-bag consolidated after wet layup to optimize impact and environmental resistance and reduce surface preparation for painting.

“We made tests to minimize this assembly weight,” notes Lallemand. “We asked laminators to make test joints and then we cut and tested these for weight and resin-to-fiber ratio.”

Although assembly of the hull, arms, amas, deck and superstructure took three months, H2X’s overall attention to process control paid dividends: The weights of the first and second boats’ main hulls differed by less than 5 kg — impressive for such a large structure. “Within 100 kg would have been good,” quips Lallemand, adding that each boat’s complete composite structure weighs less than 30 MT.

Delivering versatility

The first three Ocean Eagle 43s will be delivered to Mozambique in 2015. CMN has been so pleased with the design concept that it introduced a mine-hunter version of the Ocean Eagle 43 in Le Bourget, France, at the 24th International Naval, Defence & Maritime Exhibition (Euronaval, Oct. 27-31, 2014). The company says it now offers an “ideal” solution for navies seeking simple, modular and versatile platforms, which can be assigned not only to surveillance and minehunting, but a variety of other patrol missions.

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreComposites-reinforced concrete for sustainable data center construction

Metromont’s C-GRID-reinforced insulated precast concrete’s high strength, durability, light weight and ease of installation improve data center performance, construction time and sustainability.

Read MoreThermoset-thermoplastic joining, natural fibers enable sustainability-focused brake cover

Award-winning motorcycle brake disc cover showcases potential for KTM Technologies’ Conexus joining technology and flax fiber composites.

Read MoreRead Next

Plant tour: A&P, Cincinnati, OH

A&P has made a name for itself as a braider, but the depth and breadth of its technical aptitude comes into sharp focus with a peek behind usually closed doors.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreModeling and characterization of crushable composite structures

How the predictive tool “CZone” is applied to simulate the axial crushing response of composites, providing valuable insights into their use for motorsport applications.

Read More

%20sdm2.jpg;width=860)

.jpg;maxWidth=300;quality=90)